Online automatic monitoring method and device for residual concentration of hydrogen peroxide

A hydrogen peroxide, automatic monitoring technology, applied in measurement devices, color/spectral characteristic measurement, material analysis by optical means, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

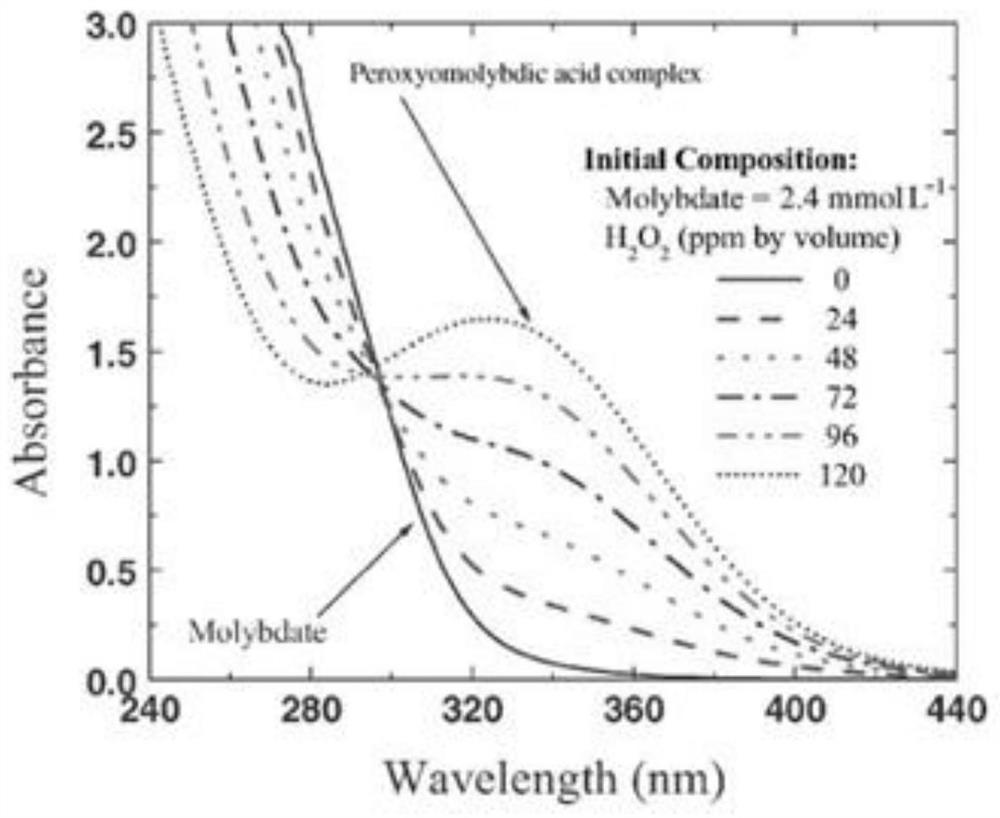

Method used

Image

Examples

Embodiment 1

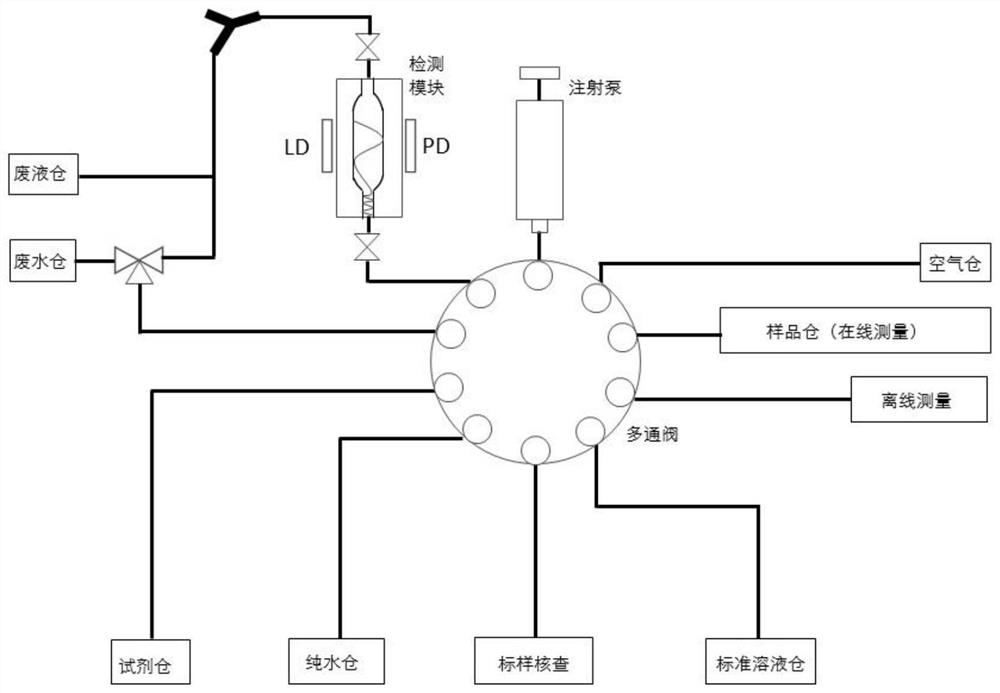

[0045] figure 2 It is the online automatic monitoring flow diagram of hydrogen peroxide residual concentration in the embodiment of the present invention;

[0046] See figure 2 , the online automatic monitoring method of hydrogen peroxide residual concentration in the raffinate of the embodiment of the present invention, comprises the following steps:

[0047] S1. Preparations before measurement

[0048] (1) Check before measurement to confirm that the remaining amount of reagents in the online analyzer is sufficient, the connections of each pipeline are correct and firm, and the parameter settings are correct;

[0049] (2) Start the on-line analyzer, use the syringe pump to extract the liquid to be tested in the sample bin and the corresponding pipeline for rinsing, and drain the waste liquid after rinsing to the waste liquid bin;

[0050] (3) Extract 1.5ml of raffinate from the sample chamber through the syringe pump, automatically calculate and inject 1ml of raffinate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com