Sensitivity matrix ultrasonic inversion method for coating surface and interface integrity parameters

A sensitivity matrix, surface interface technology, applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, processing detection response signals, etc., can solve ill-posed, non-unique, coating ultrasonics Detect problems such as non-linearity, achieve great economic benefits, wide application range, and high quantitative accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

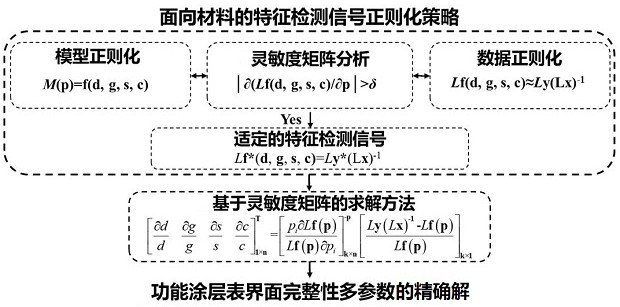

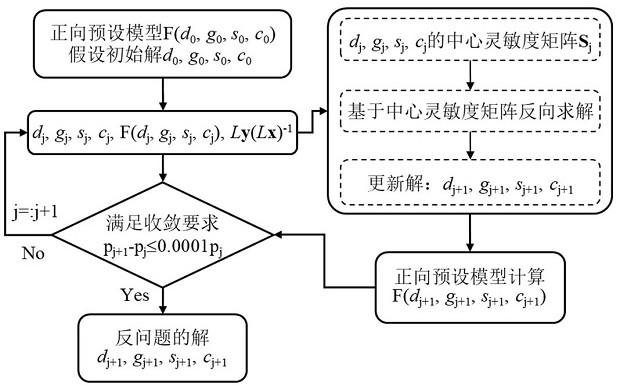

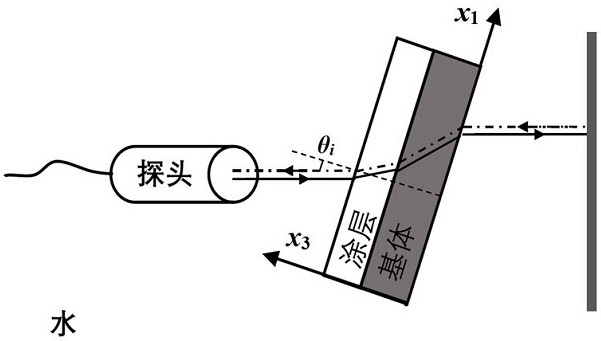

[0025] figure 1 , 2 A schematic diagram and flow chart of a sensitivity matrix ultrasonic inversion method for the integrity parameters of the coating surface and interface are shown. The sensitivity matrix-based multi-parameter ultrasonic inversion method for surface and interface integrity of functional coatings in the figure includes model regularization, sensitivity matrix analysis, data regularization, and sensitivity matrix-based inversion, combined with model regularization, data regularization and Based on the sensitivity matrix analysis and inversion, the precise solution of the multi-parameters of the surface and interface integrity of the functional coating is obtained. Al by plasma spraying 2 o 3 The ultrasonic detection of multiple unknown elastic constants of the coating is taken as an example to illustrate the application effect of the multi-parameter ultrasonic inversion method for the surface and interface integrity of functional coatings based on the sens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com