Anti-corrosion etching method for single-chip wet cleaning machine

A wet cleaning and machine technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as increasing the risk of fragmentation, reducing etching uniformity, and low fault tolerance. Achieve the effect of reducing the risk of fragmentation, ensuring the uniformity of etching, and improving the fault tolerance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

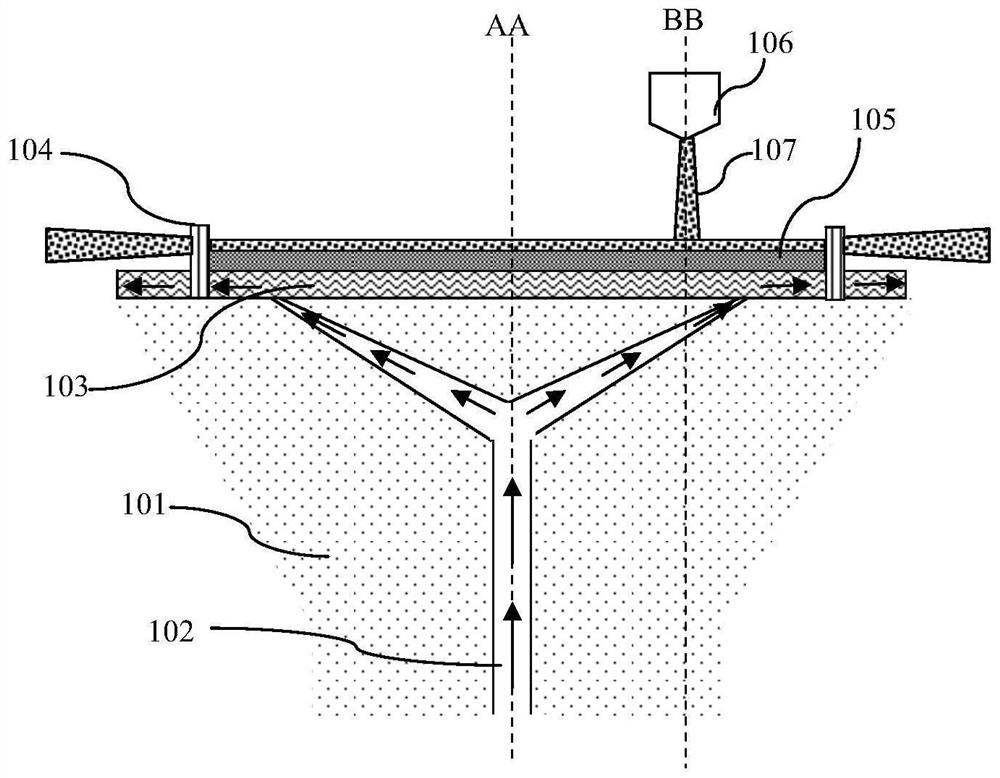

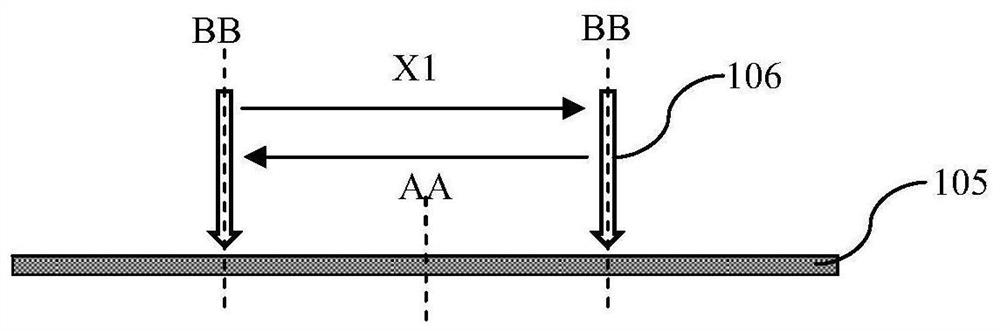

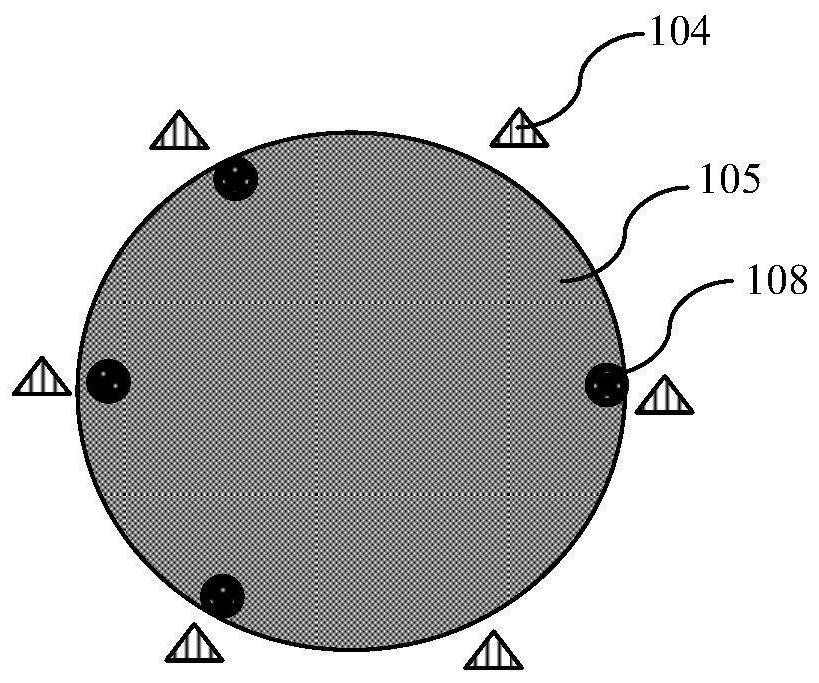

[0068] like Figure 5 Shown is the flow chart of the etching method for anti-corrosion of the monolithic wet cleaning machine platform of the embodiment of the present invention; Figure 6 As shown, it is a schematic cross-sectional structure diagram of the clamping device 101 in the etching method for anti-corrosion of the single-chip wet cleaning machine according to the embodiment of the present invention; Figure 7 As shown, it is a schematic diagram of the injection position of the liquid supply nozzle 106 in the etching method for anti-corrosion of the single-chip wet cleaning machine of the embodiment of the present invention; the anti-corrosion of the single-chip wet cleaning machine of the embodiment of the present invention The etching method comprises the following steps:

[0069] Step 1. Fix the wafer 105 on the clamping device 101 of the single-chip wet cleaning machine, the edge of the wafer 105 is in contact with the thimble 104 on the clamping device 101, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com