A technology for improving the service life of etching solution

A chemical solution and life-span technology, applied in the field of etching, can solve the problems of reduced filling factor, increased dark current, reduced etching efficiency, etc., and achieves the effect of ensuring etching uniformity, prolonging service life, and increasing solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

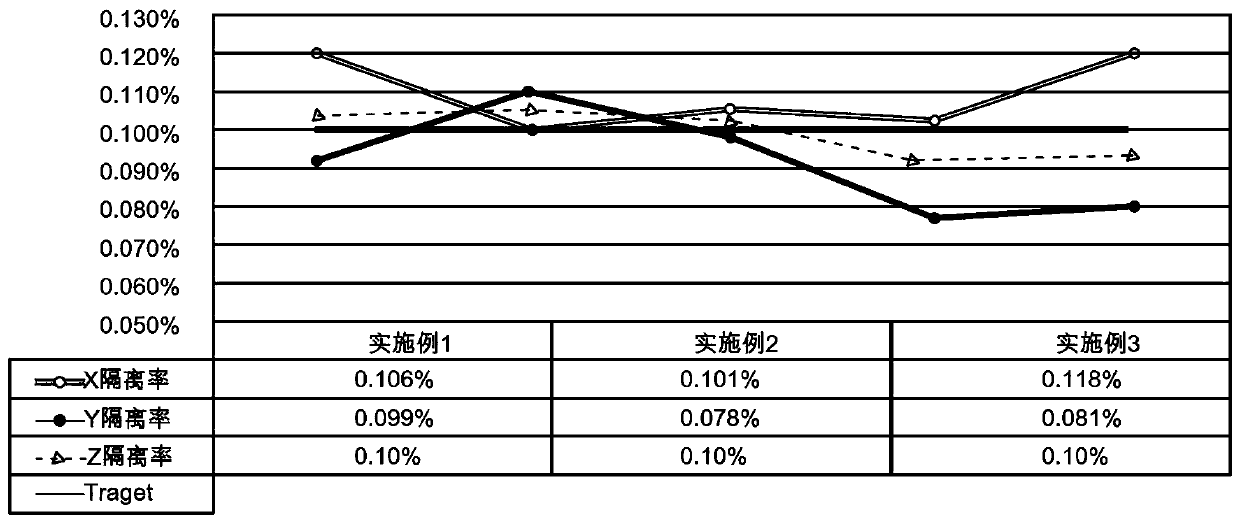

Embodiment 1

[0026] A process for improving the service life of etching liquid, comprising the following steps:

[0027] Step 1): Add 2% by mass neutral salt to the etching liquid with low chemical activity, and simultaneously add 13‰ ethoxylate, mix and stir evenly;

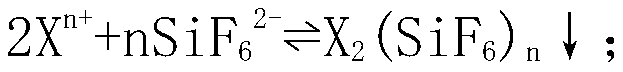

[0028] SiF in the etching solution 6 2- The general formula for the reaction of anion and magnetic cation for neutral salt hydrolysis is as follows:

[0029] H in etching solution + The general formula for the reaction of cations and anions in neutral salt hydrolysis is as follows:

[0030] Step 2): The mixed solution after stirring is 20kHz cavitation through the magnetic field strength, and then the precipitate in the solution after cavitation (X 2 ) (SiF 6 ) n Filter out, filter out the precipitate (X 2 ) (SiF 6 ) n After the solution passes through ion exchange resin again, obtains filtrate;

[0031] Step 3): adding deionized water to the filtrate in step 2) to form a new solution, keeping the pH value at...

Embodiment 2

[0037] A process for improving the service life of etching liquid, comprising the following steps:

[0038] Step 1): Add 9% by mass of neutral salt to the etching liquid with low activity of the liquid, and at the same time add ethoxylates with a mass of 25‰, mix and stir evenly;

[0039] SiF in the etching solution 6 2- The general formula for the reaction of anion and magnetic cation for neutral salt hydrolysis is as follows:

[0040] H in etching solution + The general formula for the reaction of cations and anions in neutral salt hydrolysis is as follows:

[0041]Step 2): it is 30kHz cavitation that the mixed solution after stirring is passed through the magnetic field intensity, and then the precipitate in the solution after cavitation (X 2 ) (SiF 6 ) n Filter out, filter out the precipitate (X 2 ) (SiF 6 ) n After the solution passes through ion exchange resin again, obtains filtrate;

[0042] Step 3): adding deionized water to the filtrate in step 2) to ...

Embodiment 3

[0047] A process for improving the service life of etching liquid, comprising the following steps:

[0048] Step 1): Add 15% by mass neutral salt to the etching solution with low activity of the solution, and simultaneously add 40‰ of ethoxylate, mix and stir evenly;

[0049] SiF in the etching solution 6 2- The general formula for the reaction of anion and magnetic cation for neutral salt hydrolysis is as follows:

[0050] H in etching solution + The general formula for the reaction of cations and anions in neutral salt hydrolysis is as follows:

[0051] Step 2): The mixed solution after stirring is subjected to cavitation with a magnetic field strength of 20 to 40 kHz, and then the precipitate in the solution after cavitation (X 2 ) (SiF 6 ) n Filter out, filter out the precipitate (X 2 ) (SiF 6 ) n After the solution passes through ion exchange resin again, obtains filtrate;

[0052] Step 3): adding deionized water to the filtrate in step 2) to form a new so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com