Multilayer thick-film ceramic-based circuit board and preparation process thereof

A preparation process and ceramic substrate technology, which is applied in the direction of printed circuit manufacturing, printed circuit, circuit heating device, etc., can solve the problem that the heat conduction effect of ceramic substrate is not particularly ideal, so as to avoid mechanical or laser drilling, facilitate heat dissipation, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

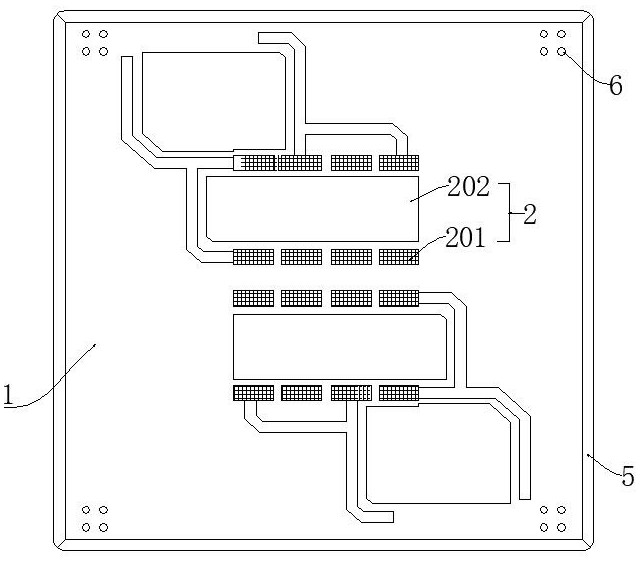

[0036] like Figure 1~Figure 4 As shown, this solution discloses a ceramic substrate 1 , a copper clad layer 2 , and a cladding layer that are laminated sequentially from bottom to top by a multilayer thick-film ceramic-based circuit board.

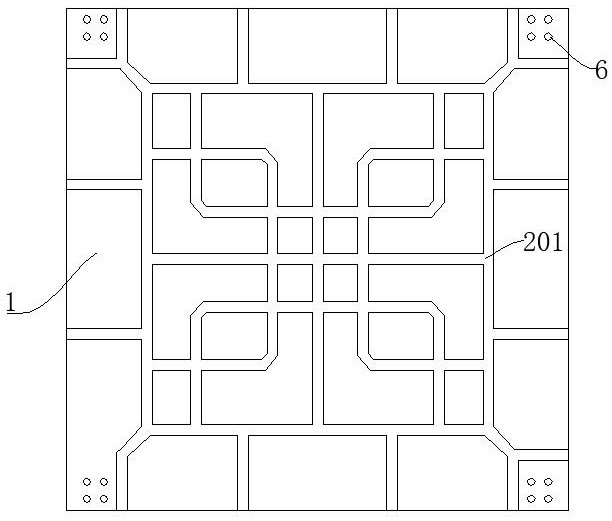

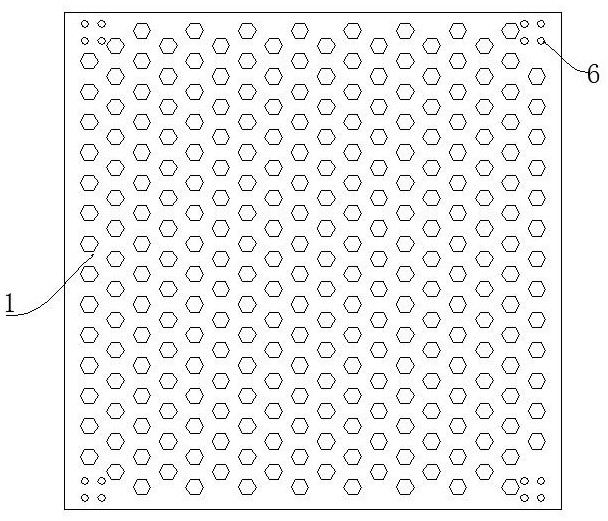

[0037] In this solution, the ceramic substrate 1 includes a ceramic plate A3 and a ceramic plate B4, the ceramic plate A3 is in the shape of a grid, the ceramic plate B4 is in the shape of a whole plate, and two ceramic plates B4 clamp and bond the ceramic plate A3. In this way, heat dissipation holes are formed between the mesh holes.

[0038] In this solution, the copper clad layer 2 is bonded to the surface of the ceramic board B4, after which a printed circuit line 201 and a heat dissipation copper area 202 are formed. The heat diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com