Heat dissipation device based on graphene heating chip

A heating chip and heat dissipation device technology, which is applied in the direction of cooling/ventilation/heating transformation, modification through conduction heat transfer, etc., can solve the problems of poor heat dissipation effect and easy deformation of the heating chip, and achieve improved heat conduction effect, convenient operation, and difficult deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

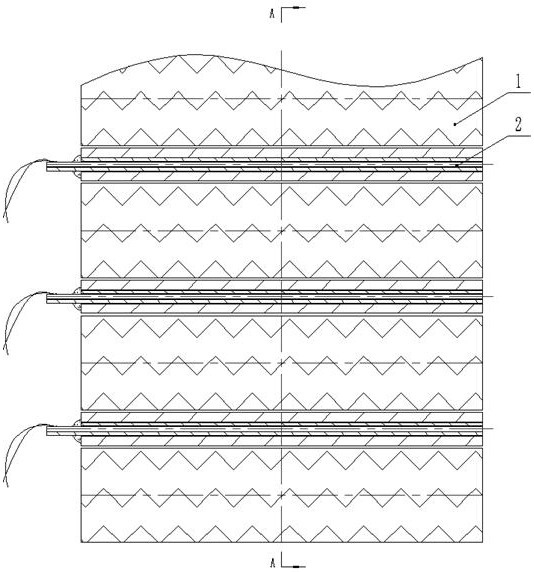

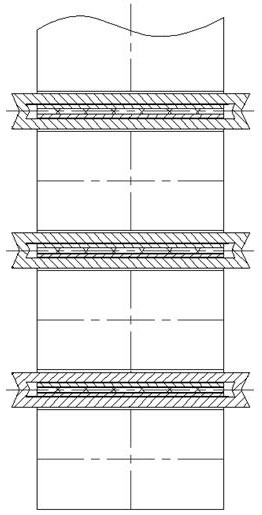

[0023] Such as figure 1 Shown is a heat dissipation device based on a graphene heating chip, comprising a support, several layers of radiators 1 arranged in sequence from top to bottom, and a graphene heater 2 arranged between adjacent two layers of radiators, radiator and The graphene heating body is fixedly connected with the support to form a whole radiator. The heat sink in this embodiment is a corrugated heat dissipation aluminum strip to ensure smooth heat conduction. In practical applications, different numbers of heat dissipation aluminum strips are selected to form heat sinks with different powers as required.

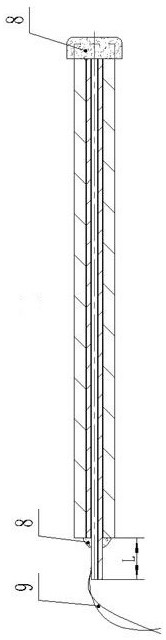

[0024] The graphene heating body includes a heat conduction shell 3 which is in contact with the radiator, and a graphene chip 7 fixed in the heat conduction shell, and the contacts of the graphene chip ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com