Coating and application system and method for seed fertilizer and pesticide

A coating and hanger technology is applied in the fields of botanical equipment and methods, seed coating/seed dressing, layering/coating fertilizer, etc. Slow release of fertilizer and pesticide coating and automatic intelligent and precise control to ensure stability and effectiveness, quantitative and precise application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

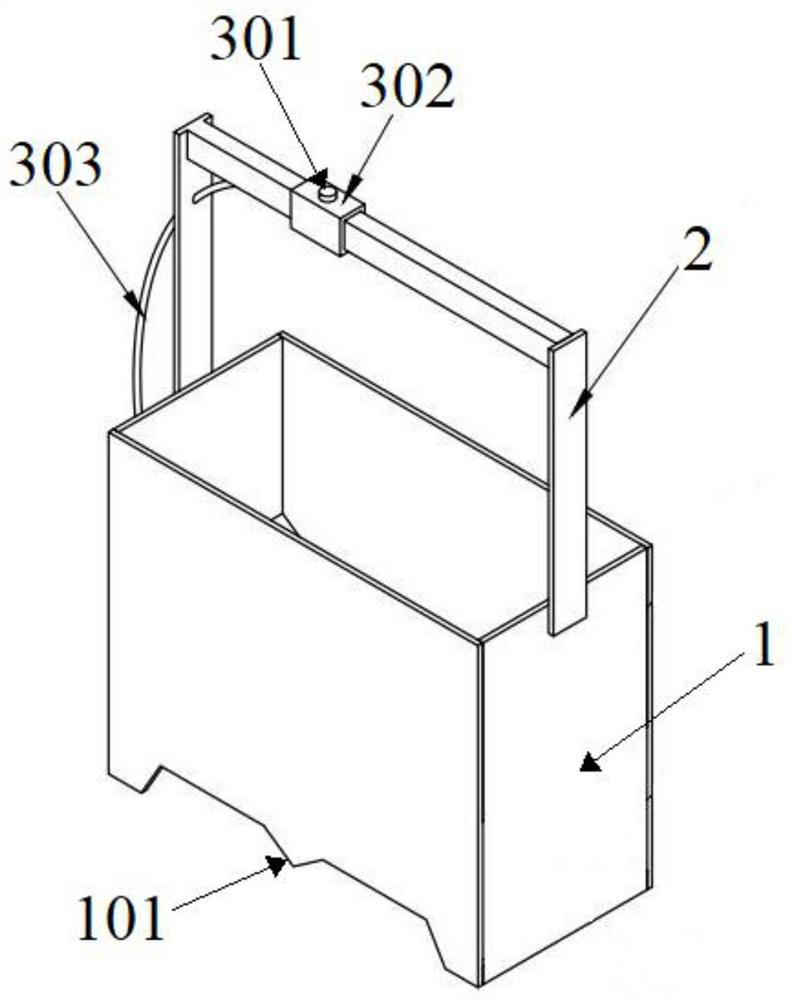

[0098] Such as Figure 1-2 As shown, a kind of fertilizer coating and application system, the system includes a box body 1 and a handle 2 arranged at the upper end of the box body 1 . The inner cavity of the box body 1 is provided with a feed box 5 , a roll-on coating device 6 and a discharge box 8 sequentially from top to bottom. The discharge port of the feed box 5 communicates with the feed port of the roll-on coating device 6 . The discharge port of the roll coating device 6 communicates with the feed port of the discharge box 8 . A control feeder 7 is also provided at the discharge port of the discharge box 8 .

Embodiment 2

[0100]Embodiment 1 is repeated, except that the system further includes a power supply device 3 . The power supply device 3 includes a power button 301 , a power supply 302 and a connection line 303 . The power button 301 is arranged on the handle 2 . The power supply 302 is arranged on the box body 1 or the handle 2 . The power supply 302 is independently connected to the feed box 5 , the roll-on coating device 6 , and the control discharge device 7 through the connection line 303 . That is, the power supply 302 independently controls the start and stop of the feed box 5 , the roll-up coating device 6 , the discharge device 7 and the opening and closing of their respective inlet and outlet ports through the connection line 303 .

Embodiment 3

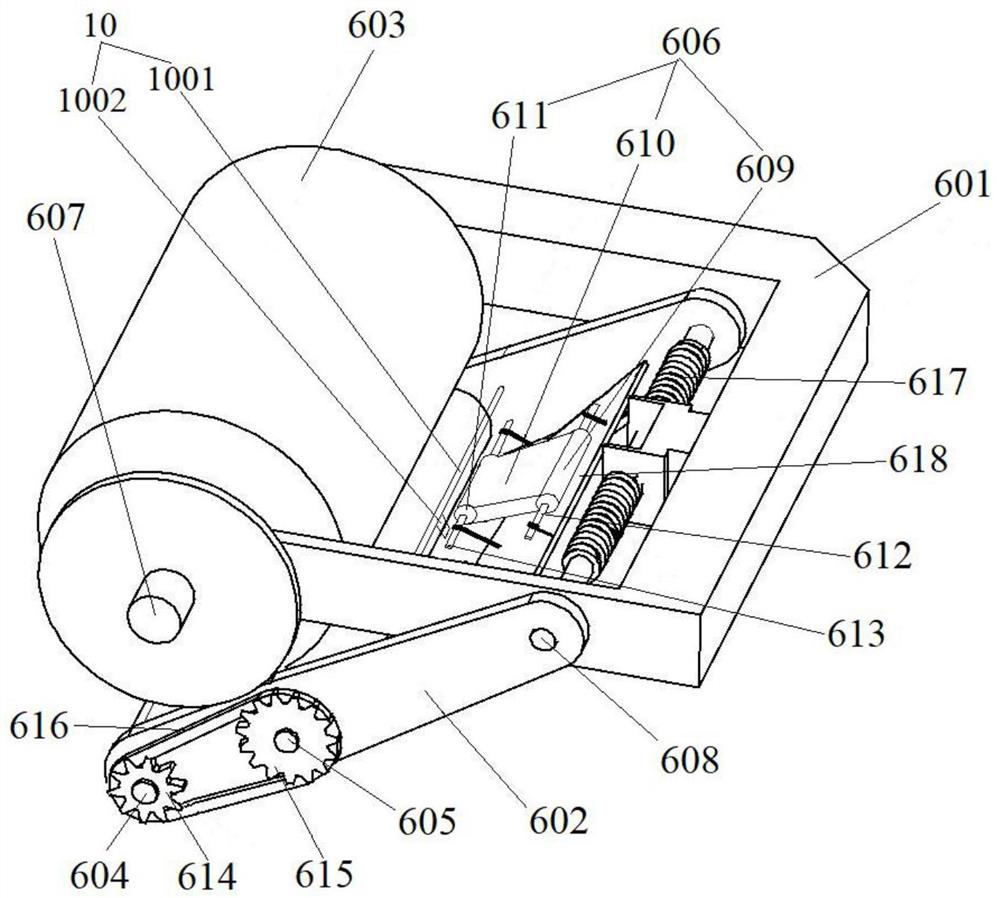

[0102] Repeat Example 2, such as image 3 As shown, only the rolling coating device 6 includes a clothes roll rack 601 , a clothes guide rack 602 , a clothes roll 603 , a first clothes guide shaft 604 , a second clothes guide shaft 605 and a material guide belt conveyor 606 . The top of the clothes guide rack 602 is movably connected with one end of the clothes roll rack 601 . The clothes roll 603 is arranged at the other end of the clothes roll rack 601 . The first clothes guiding shaft 604 is arranged at the bottom of the clothes guiding rack 602 . The second clothes guiding shaft 605 is arranged on the clothes guiding rack 602 and is located on the upper side of the first clothes guiding shaft 604 . The material guide belt conveyor 606 is arranged on the clothes guide rack 602 and is located on the upper side of the second clothes guide shaft 605 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com