Monatomic catalytic material for removing refractory organic pollutants and preparation method of monatomic catalytic material

A technology of organic pollutants and catalytic materials, applied in the field of single-atom catalytic materials and their preparation, can solve the problems of narrow optimum pH range, easy to produce a large amount of iron sludge, low rate constant, etc., and achieve short preparation cycle and good repeatability Ease of use and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

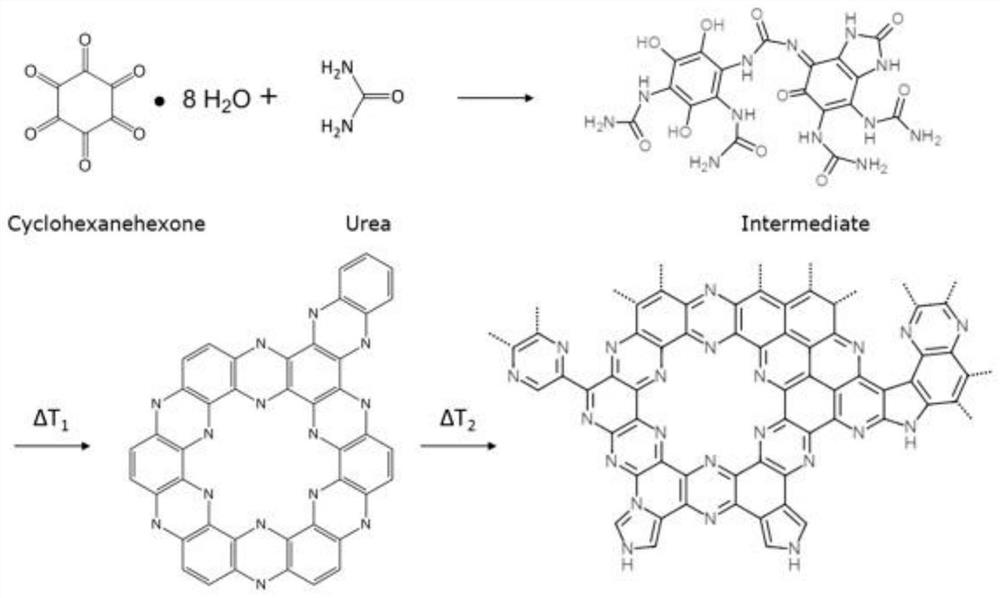

[0037] The invention provides a method for preparing a single-atom catalytic material for the removal of refractory organic pollutants, comprising the following steps:

[0038]S1: put a certain quality of C 6 o 6 and CH 4 N 2 After O is ground and mixed for a certain period of time, it is placed in a quartz crucible and heated at a low temperature to form a eutectic mixture.

[0039] Further, in an optional embodiment of the present invention, C 6 o 6 and CH 4 N 2 The mass ratio of O is 1:0.5-5; preferably, C 6 o 6 and CH 4 N 2 The mass ratio of O is 1:0.5-2; preferably, C 6 o 6 and CH 4 N 2 The mass to mass ratio of O is 1:1.

[0040] Further, in an optional embodiment of the present invention, the temperature of low-temperature heating is 60-150°C.

[0041] S2: After the eutectic mixture is cooled to room temperature, it is further ground and mixed with a certain quality of chloride salt, and the mixture is heated under the protection of nitrogen atmosphere. ...

Embodiment 1

[0059] A method for preparing a single-atom catalytic material for the removal of refractory organic pollutants, comprising the following steps:

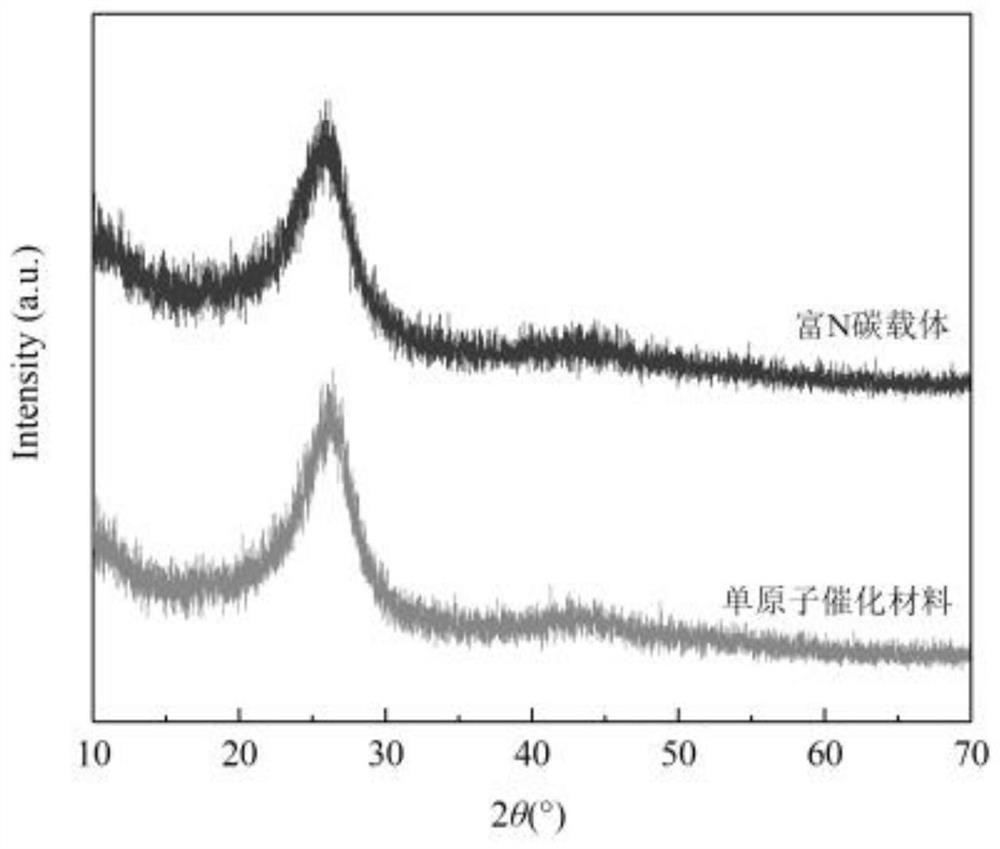

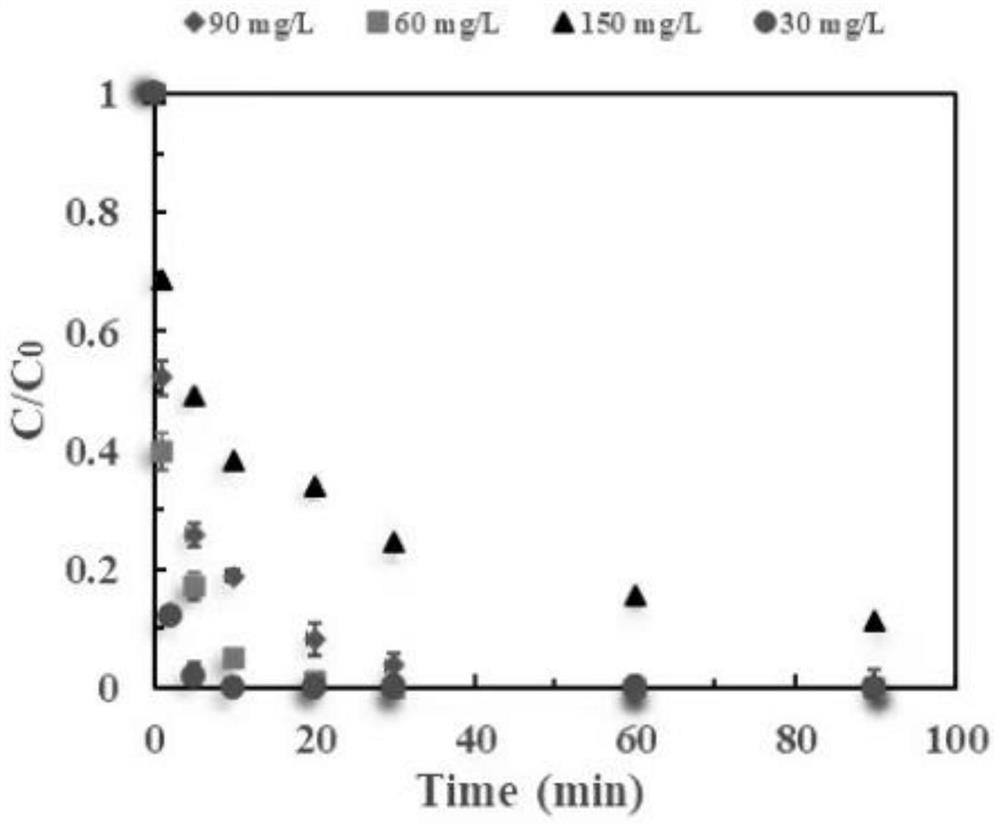

[0060] 2.5gC 6 o 6 with equal mass of CH 4 N 2 O mix well and grind for 10 minutes. The resulting mixture was placed in a quartz crucible and heated at 90 °C for 1 h to form a eutectic mixture. After the product is cooled to room temperature, it is further mixed with 10.0g ZnCl 2 Mix and grind for 15 minutes. Further, the eutectic mixture was heated to 600° C. under a nitrogen atmosphere at a heating rate of 2.5° C. / min for 1 hour. Thereafter, the resulting product was rinsed with deionized water to remove residual ZnCl 2 , and placed in a vacuum oven for drying. 0.2mol / LFeCl 3 ·6H 2 The O solution was mixed with 0.2 g of N-rich carbon material to obtain a suspension, and then the water in the mixture was removed by a rotary evaporator, and the traditional H 2 The reduction method further uniformly disperses Fe atoms on t...

Embodiment 2

[0062] A method for preparing a single-atom catalytic material for the removal of refractory organic pollutants, comprising the following steps:

[0063] 2.5gC 6 o 6 with equal mass of CH 4 N 2 O mix well and grind for 10 minutes. The resulting mixture was placed in a quartz crucible and heated at 90 °C for 1 h to form a eutectic mixture. After the product is cooled to room temperature, it is further mixed with 10.0g ZnCl 2 Mix and grind for 15 minutes. Further, the eutectic mixture was heated to 600° C. under a nitrogen atmosphere at a heating rate of 2.5° C. / min for 1 hour. Thereafter, the resulting product was rinsed with deionized water to remove residual ZnCl 2 , and placed in a vacuum oven for drying. 0.2mol / LFeCl 3 ·6H 2 The O solution was mixed with 0.2 g of N-rich carbon material to obtain a suspension, and then the water in the mixture was removed by a rotary evaporator, and the traditional H 2 The reduction method further uniformly disperses Fe atoms on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com