Method for homogeneous synthesis of di (2-ethylhexyl) terephthalate

A technology of terephthalic acid and tetrabutyl titanate, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of human carcinogenesis and high energy consumption in the reaction process, and achieve improved efficiency, The effect of shortening the reaction time and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 homogeneously prepares the method for DOTP

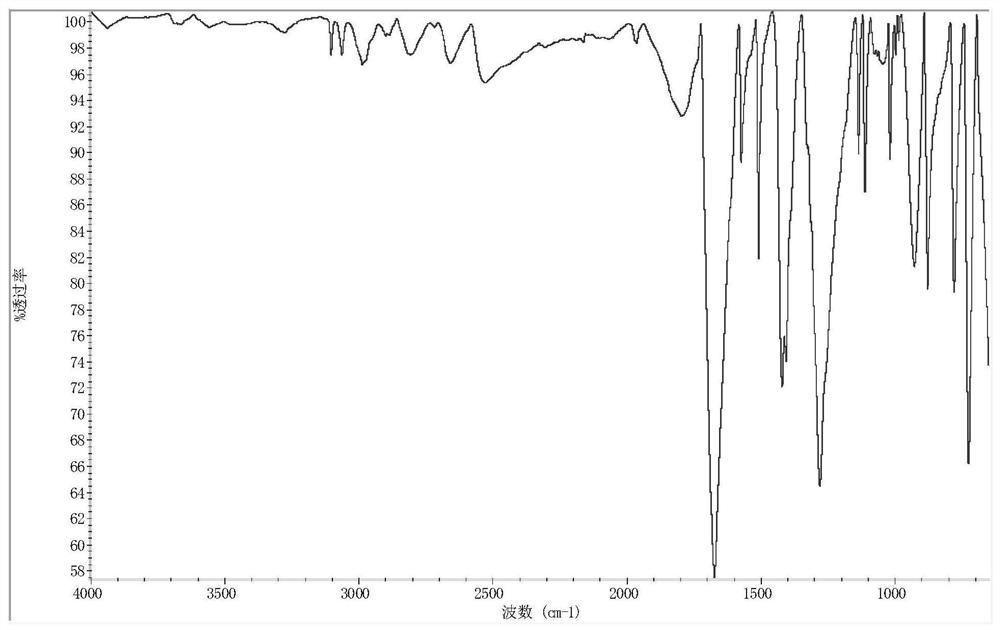

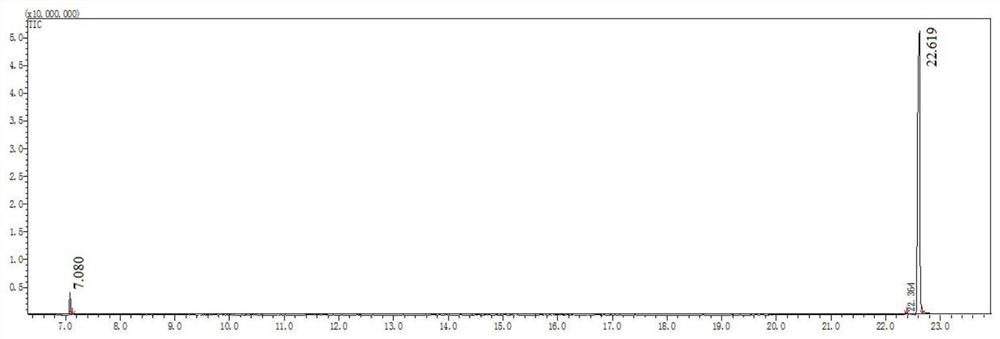

[0027] In a three-necked flask equipped with stirring, condensation and a thermometer, add 0.1mol (16.6g) of PTA, NMP 0.6mol (59.48g), 0.3mol of isooctyl alcohol, and add acid alcohol total mass 1wt% when the temperature rises to 180°C The tetrabutyl titanate was kept warm for 0.5h, and then the temperature was raised to 220°C for reaction. After 4h of reaction, the acid value of the system no longer decreased, and the reaction was stopped at this time. After cooling and centrifuging, the crude product is washed and neutralized with 5% aqueous sodium bicarbonate solution; finally, vacuum distillation is carried out at -0.1Mpa, 160°C, and 5% activated carbon is added for decolorization at -0.1Mpa, 70°C to obtain the final product. The esterification rate of the product obtained is 99.6%.

Embodiment 2

[0029] Referring to Example 1, using the amounts of NMP shown in Table 1 respectively, and other conditions unchanged, corresponding esterification was carried out. The results are shown in Table 1.

[0030] Table 1

[0031] PTA: NMP (molar ratio) Esterification rate 1:1 99.82 1:2 99.86 1:3 99.79 1:4 97.11 1:5 98.95 1:6 99.60

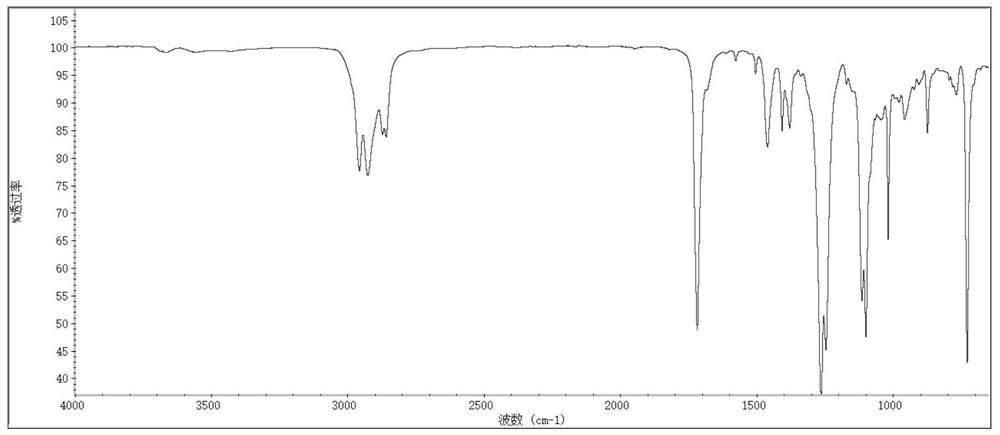

[0032] The method for comparative example 1 heterogeneous phase preparation DOTP

[0033] Esterification in a solid-liquid heterogeneous system: In a three-necked flask equipped with stirring, condensation and a thermometer, add 0.1 mol of PTA, 0.3 mol of iso-octanol, and add 1% of the total mass of titanic acid when the temperature rises to 180°C Tetrabutyl ester was kept warm for 0.5h, and then the temperature was raised to 220°C for reaction. After 8h of reaction, the acid value of the system no longer decreased, and the reaction was stopped at this time. After cooling and centrifuging, washing and neu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com