Intercalation type hydrotalcite flame-retardant smoke suppressant and preparation method thereof

A hydrotalcite and smoke suppressant technology, applied in the field of flame retardants, can solve the problem of reducing the flame retardant and smoke suppression efficiency of hydrotalcite, it is difficult for flame retardants to have high flame retardant and smoke suppression and effective enhancement modification, and poor polymer compatibility and other problems, to achieve the effect of reducing secondary pollution, good effect of flame retardant and smoke suppression, and improvement of compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

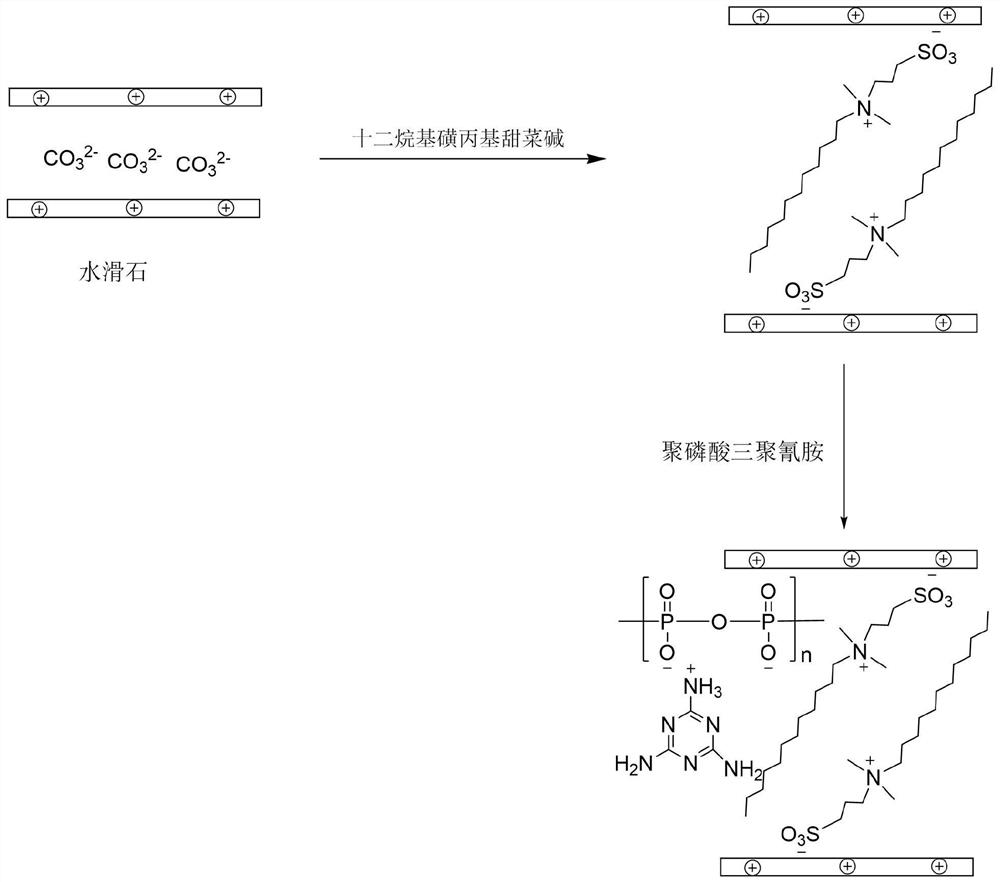

[0028] Add 1L of distilled water and 100g of hydrotalcite into a stainless steel reaction kettle, ultrasonically disperse for 30 minutes, add 6g of dodecyl sulfopropyl betaine, stir and react at 60°C for 15 hours, and wash the filtered product with distilled water several times. The obtained solid is blast-dried to constant weight to obtain hydrotalcite treated with dodecyl sulfopropyl betaine surface organic treatment.

[0029] Add 100 g of the above-mentioned dodecyl sulfopropyl betaine surface organically treated hydrotalcite into 1 L of distilled water, ultrasonically disperse it for 30 minutes, then transfer it to a three-necked flask equipped with a mechanical stirrer, a thermometer, and a reflux condenser, and add dropwise 3g melamine polyphosphate / hydrochloric acid solution, the pH value is 5.0, stirred and reacted at 25°C for 8 hours, then filtered the suspension obtained by the reaction, washed three times with distilled water, and dried in an oven at 100°C for 24 hou...

Embodiment 2

[0031] Add 1L of distilled water and 100g of hydrotalcite into a stainless steel reactor, ultrasonically disperse for 30 minutes, add 20g of dodecyl sulfopropyl betaine, stir and react at 90°C for 4 hours, wash the filtered product with distilled water several times, The obtained solid is blast-dried to constant weight to obtain hydrotalcite treated with dodecyl sulfopropyl betaine surface organic treatment.

[0032] Add 100 g of the above-mentioned dodecyl sulfopropyl betaine surface organically treated hydrotalcite into 1 L of distilled water, ultrasonically disperse it for 30 minutes, then transfer it to a three-necked flask equipped with a mechanical stirrer, a thermometer, and a reflux condenser, and add dropwise 15g melamine polyphosphate / hydrochloric acid solution, the pH value is 3.0, stirred and reacted at 60°C for 2 hours, then filtered the suspension obtained by the reaction, washed three times with distilled water, and dried in an oven at 100°C for 24 hours to obtai...

Embodiment 3

[0034] Add 1L of distilled water and 100g of hydrotalcite into a stainless steel reaction kettle, ultrasonically disperse for 30 minutes, add 15g of dodecyl sulfopropyl betaine, stir and react at 70°C for 6 hours, and wash the filtered product with distilled water several times. The obtained solid is blast-dried to constant weight to obtain hydrotalcite treated with dodecyl sulfopropyl betaine surface organic treatment.

[0035] Add 100 g of the above-mentioned dodecyl sulfopropyl betaine surface organically treated hydrotalcite into 1 L of distilled water, ultrasonically disperse it for 30 minutes, then transfer it to a three-necked flask equipped with a mechanical stirrer, a thermometer, and a reflux condenser, and add dropwise 8g melamine polyphosphate / hydrochloric acid solution, the pH value is 4.5, stirred and reacted at 45°C for 3 hours, then filtered the suspension obtained by the reaction, washed three times with distilled water, and dried in an oven at 100°C for 24 hou...

PUM

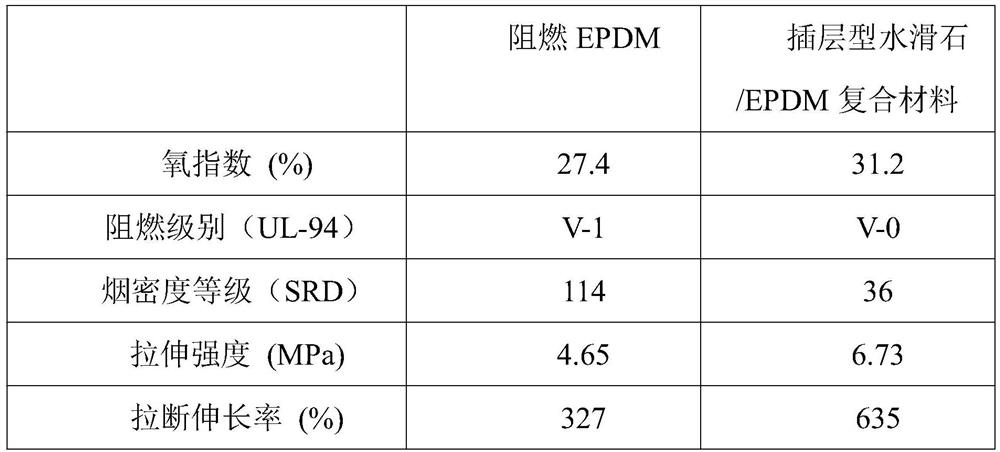

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com