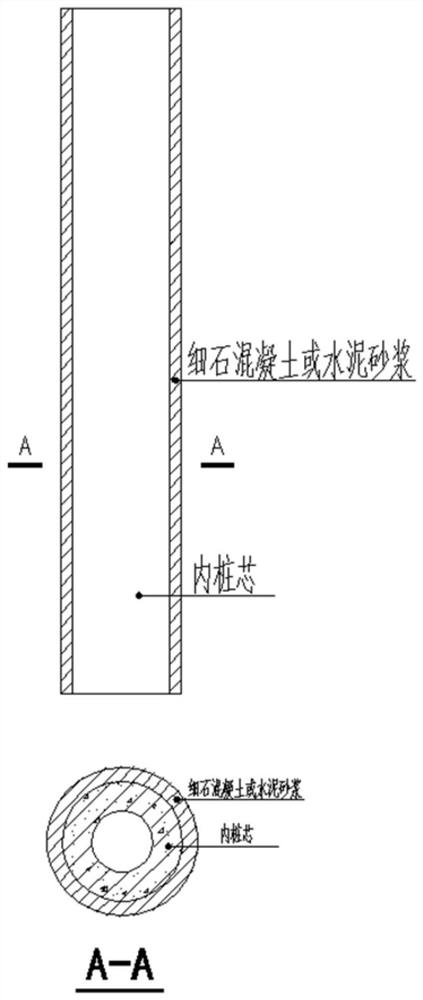

Stiff composite pile construction process

A construction technique and composite pile technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as difficult to meet requirements and large impact, and achieve the effects of reliable quality, convenient construction, and fast pile formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

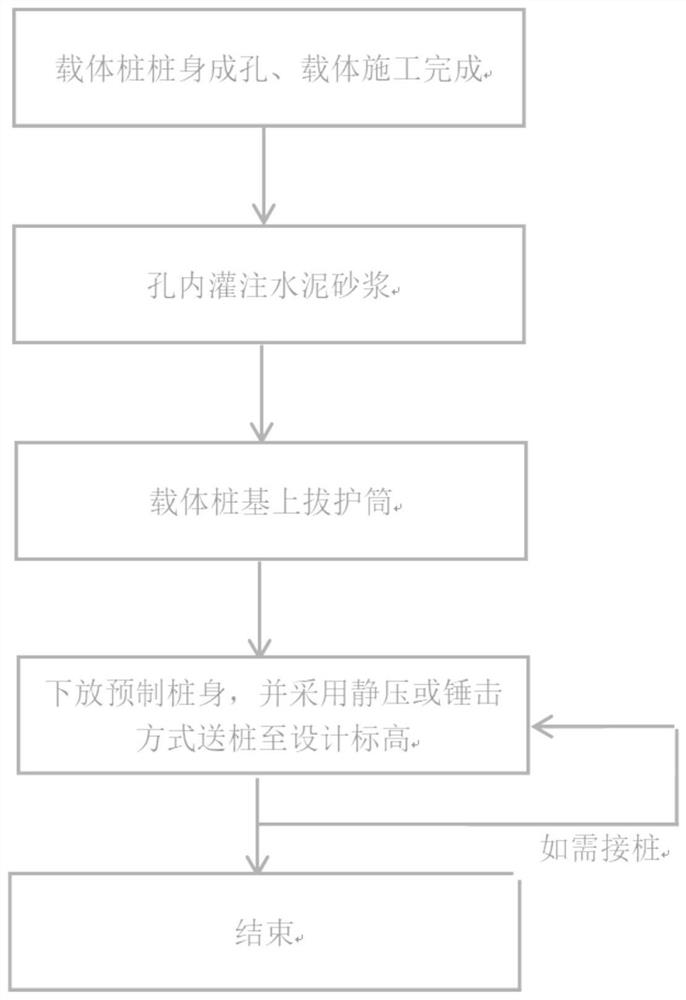

[0031] S1: Carrier pile construction

[0032] a. The carrier pile adopts φ500mm cement-soil mixing pile, and the full casing follows the impact to form a hole. The hole is filled with cement mortar. The cement mixing amount in the empty drilling area is 9%, and the cement mixing amount in the effective pile length area is 17%;

[0033] b. The carrier construction is completed and the pile driver is in place.

[0034] S2: Carrier pile driver pulls up the casing

[0035] S3: Lower the prefabricated pile body, and send the pile to the design elevation by static pressure or hammering

[0036] a. The prefabricated pile body adopts prestressed concrete pipe pile, the effective pile length is 42m, and the prefabricated pile body is constructed within 6 hours after the carrier construction is completed;

[0037] b. After the stirring pile machine moves the machine to construct the next carrier pile, the static press is positioned and straightened, and the center error of the positio...

Embodiment 2

[0046] S1: Carrier pile construction

[0047] a. The carrier pile adopts φ700mm cement-soil mixing pile, and the full casing follows the impact to form a hole. The hole is filled with cement mortar. The cement mixing amount in the empty drilling area is 10%, and the cement mixing amount in the effective pile length area is 19%;

[0048] b. The carrier construction is completed and the pile driver is in place.

[0049] S2: Carrier pile driver pulls up the casing

[0050] S3: Lower the prefabricated pile body, and send the pile to the design elevation by static pressure or hammering

[0051] a. The prefabricated pile body adopts prestressed concrete pipe pile, the effective pile length is 42m, and the prefabricated pile body is constructed within 6 hours after the carrier construction is completed;

[0052] b. After the stirring pile machine moves the machine to construct the next carrier pile, the static press is positioned and straightened, and the center error of the positi...

Embodiment 3

[0061] S1: Carrier pile construction

[0062] a. The carrier pile adopts φ900mm cement-soil mixing pile, and the full casing follows the impact to form a hole. The hole is poured with fine stone concrete. The cement mixing amount in the empty drilling area is 9-11%, and the cement mixing amount in the effective pile length area is twenty one%;

[0063] b. The carrier construction is completed and the pile driver is in place.

[0064] S2: Carrier pile driver pulls up the casing

[0065] S3: Lower the prefabricated pile body, and send the pile to the design elevation by static pressure or hammering

[0066] a. The prefabricated pile body adopts prestressed concrete pipe pile, the effective pile length is 42m, and the prefabricated pile body is constructed within 6 hours after the carrier construction is completed;

[0067] b. After the stirring pile machine moves the machine to construct the next carrier pile, the static press is positioned and straightened, and the center er...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com