Detection method for rapidly detecting beta-stimulant and paper-based immunosensor

An immune sensor and stimulant technology, which is applied in the direction of material analysis, instruments, and measuring devices through observation of the impact on chemical indicators, can solve the problems of unsuitable real-time monitoring, time-consuming and labor-intensive detection process, and achieve easy promotion and application. Simple operation and use, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

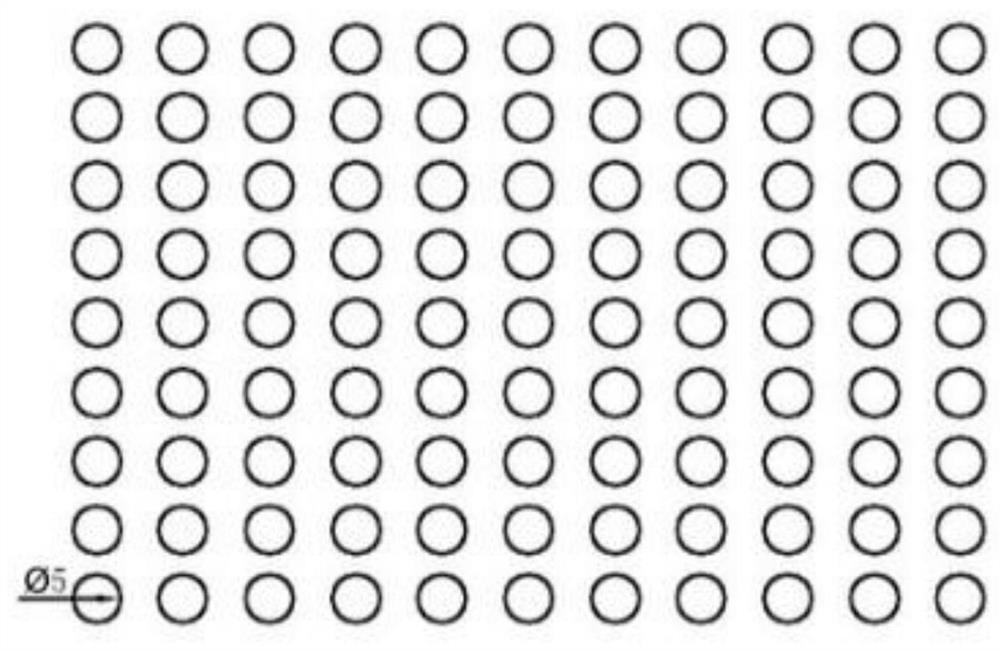

[0039] S1. Preparation of paper-based microporous plate: design the orifice plate model with drawing software, and the shape and size of the orifice plate model can be changed according to requirements;

[0040] Then, use a color printer to print out the previously designed orifice plate model with hydrophobic wax on cellulose-rich filter paper,

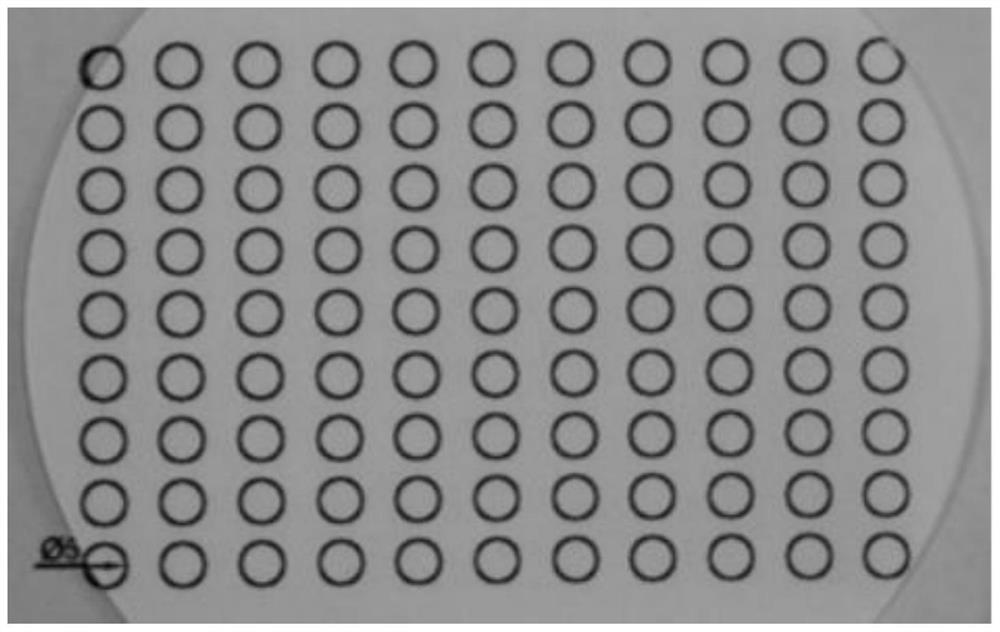

[0041] Place the filter paper with the printed orifice plate model on a magnetic heater, heat at 110-130°C for 2 minutes, so that the hydrophobic wax melts and penetrates into the filter paper, forming a hydrophobic boundary and a circular reaction area, and cools down to room temperature. It is a paper-based microporous plate;

[0042] S2. Preparation of paper-based sensors: Add 3 μL of β-agonist coating source to each circular reaction area of the paper-based microporous plate, then put the paper-based microporous plate in a constant temperature box, and heat temperature, place it for 8-12min, and wait for it to dry, wherein, th...

Embodiment 1

[0057] Embodiment 1: A paper-based immunosensor for rapid detection of clenbuterol hydrochloride, including a paper-based sensor;

[0058] The manufacturing method of the paper-based sensor is as follows:

[0059] S1. Preparation of paper-based microporous plate: use CAD drawing software to design a 96-well plate model with a pore size of 5mm, and then use a Xerox Phaser 8560N model color printer to print out the front design with hydrophobic wax on Whatman No.1 filter paper For the 96-well plate model, place the filter paper printed with the 96-well plate model on a magnetic heater, heat it at 120°C for 2 minutes, and melt the hydrophobic wax into the filter paper to form a hydrophobic boundary and a circular reaction area , cooled to room temperature, that is, a paper-based microporous plate;

[0060] S2. Preparation of paper-based sensors: Add 3 μL of β-agonist coating source to each circular reaction area of the paper-based microporous plate, and then put the paper-base...

Embodiment 2

[0073] Embodiment 2: A paper-based immunosensor for rapid detection of ractopamine, including a paper-based sensor;

[0074] The manufacturing method of the paper-based sensor is as follows:

[0075] S1. Preparation of paper-based microporous plate: use CAD drawing software to design a 96-well plate model with a pore size of 5mm, and then use a Xerox Phaser 8560N model color printer to print out the front design with hydrophobic wax on Whatman No.1 filter paper For the 96-well plate model, place the filter paper printed with the 96-well plate model on a magnetic heater, heat it at 120°C for 2 minutes, and melt the hydrophobic wax into the filter paper to form a hydrophobic boundary and a circular reaction area , cooled to room temperature, that is, a paper-based microporous plate;

[0076] S2. Preparation of paper-based sensors: Add 3 μL of ractopamine-coated raw material to each circular reaction area of the paper-based microporous plate, then put the paper-based microporo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com