Hydrothermal reaction device and system and hydrothermal treatment method

A technology of hydrothermal reaction and heat, applied in water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost and large energy consumption, and reduce the occupied area , extended reaction pathway, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

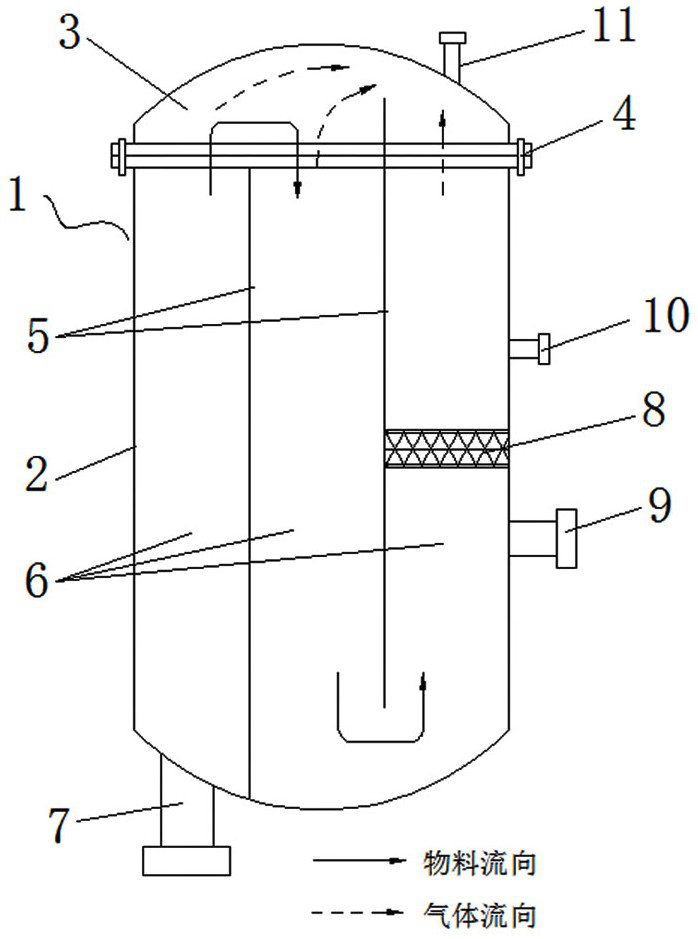

[0036] Embodiment 1: as figure 1 As shown, according to an exemplary embodiment of the present invention, the hydrothermal reaction device includes a housing 1, and the housing 1 includes a cylinder body 2 and a head 3. In this embodiment, the cylinder body 2 and the head 3 are detachable through a flange 4 The two partitions 5 are arranged in the shell 1, and the two partitions 5 separate the three material channels 6 in the shell, in order to meet the needs of the hydrothermal reaction , the number of partitions 5 inside the housing 1 can be selected according to actual needs; there is a gap for the passage of gas between the top of the partitions 5 and the top of the housing 1; a filter member 8 is arranged in the last channel, which is selected in this embodiment The filter part 8 is a filter screen, and the thick liquid outlet 9 and the clear liquid outlet 10 are respectively arranged on the wall of the housing 1 before and after the filter screen; the material inlet 7 is...

Embodiment 2

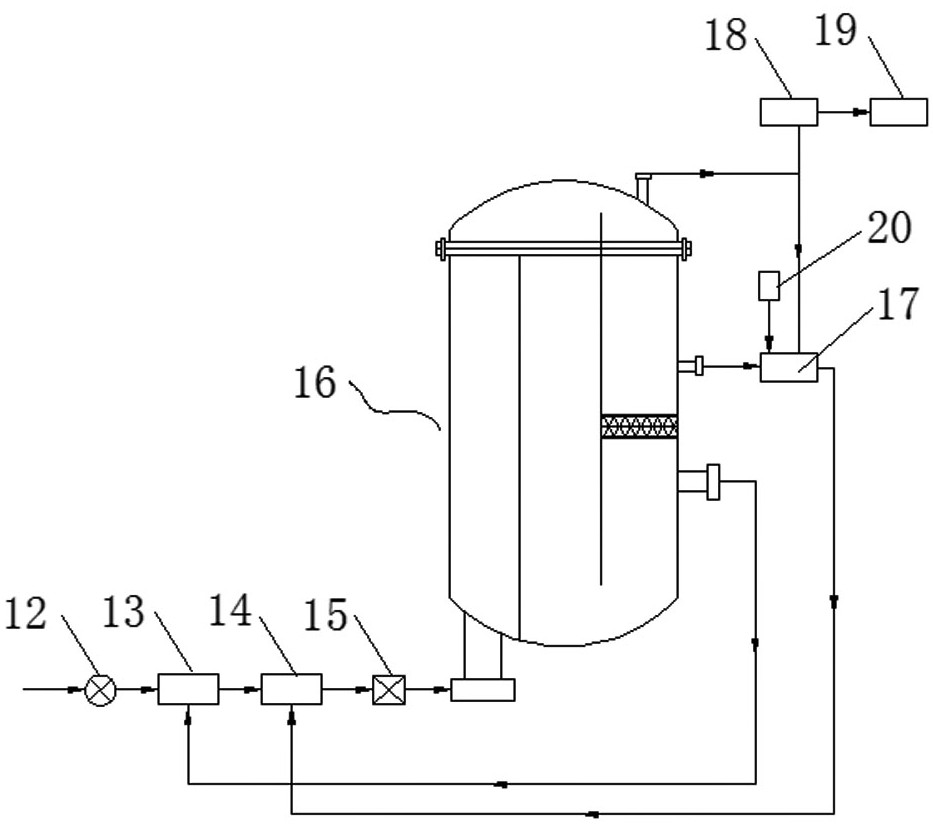

[0038] Embodiment 2: as figure 2 As shown, according to an exemplary embodiment of the present invention, the hydrothermal reaction system includes:

[0039] The material pump 12 is used to provide the power and pressure required for the material to flow in the hydrothermal reaction system;

[0040] The heat exchanger group is used to recover the heat of the liquid discharged from the hydrothermal reaction device 16 to heat the material supplied from the material pump 12; the heat exchanger group includes a first heat exchanger 13, a second heat exchanger 14 and an electric heater 15 , wherein the first heat exchanger 13 uses the heat of the concentrated liquid discharged from the hydrothermal reaction device 16 to heat the material supplied by the material pump; the second heat exchanger 14 utilizes the clear liquid discharged from the hydrothermal reaction device 16 to produce The heat of the liquid is used to heat the material heated by the first heat exchanger; the elect...

Embodiment 3

[0044] Embodiment 3: in combination with figure 1 , 2 As shown, a hydrothermal treatment method is processed by a hydrothermal reaction device and a hydrothermal reaction system. The specific method includes the following steps:

[0045] The external material enters the heat exchanger group through the material pump 12 for heating;

[0046] The heated material enters the hydrothermal reaction device 16 through the material inlet 7 to undergo a hydrothermal reaction, and the material flows through the multiple channels 6 separated by the partition plate 5 in sequence, and the organic components in the material are hydrolyzed; the material passes through the filter unit 8. The filtered clear liquid is discharged from the housing through the clear liquid outlet 10, and the concentrated liquid is discharged from the housing through the concentrated liquid outlet 9; the generated gas passes through the gap between the top of the partition and the top of the housing and then passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com