Equipment and technique for automatically grinding tooth profile fillet of precision gear by robot

A technology of robots and gear teeth, applied in the field of automatic processing of industrial robots, can solve the problems of high noise, long working hours, and more dust, and achieve the effect of saving costs and avoiding processing quality problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

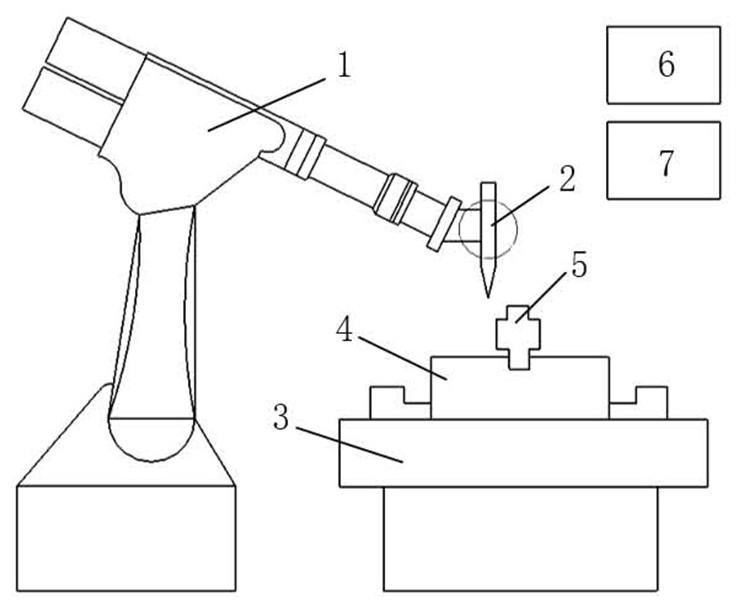

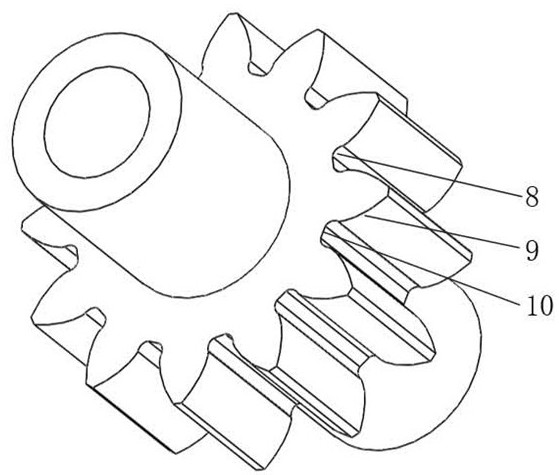

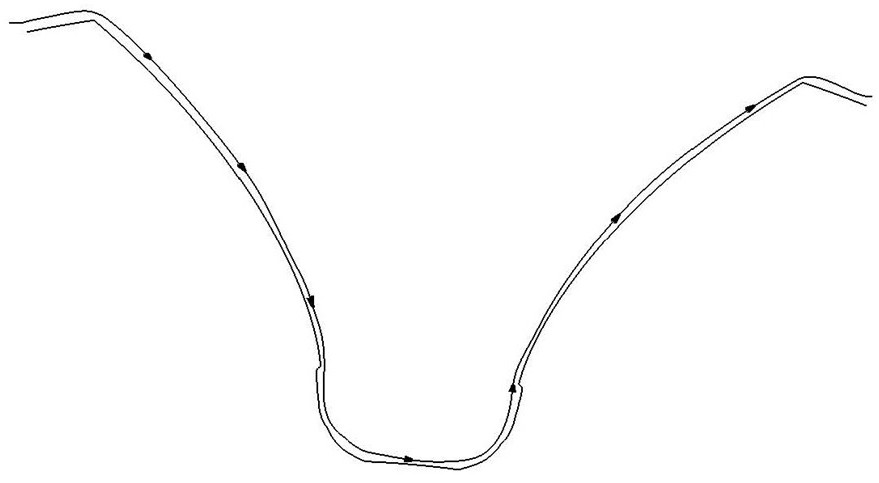

[0041] Such as figure 1As shown, the present invention provides a kind of equipment for automatically grinding precision gear tooth profile fillets by robots, including: robot module 1, grinding tool module 2, workbench module 3, positioner module 4, which are used to carry gears The positioner module 4 of the workpiece 5 is installed on the workbench module 3, the robot module 1 is arranged on one side of the workbench module 3, and the grinding tool module 2 is installed on the end effector of the robot module 1; the grinding tool module 2 Including pneumatic engraving machine 21, forming tool 22, master model 23, tool setting instrument 24, XY-horizontal slide table 25, cylinder 26, first L-shaped connecting plate 27, second L-shaped connecting plate 28 and connecting plate 29 , the front end of the pneumatic engraving machine 21 is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com