A method for synthesizing uniform spherical nano-cerium oxide material at low temperature

A nano-cerium oxide, spherical technology, applied in the direction of cerium oxide/cerium hydroxide, lanthanide oxides/hydroxides, rare earth metal oxides/hydroxides, etc., can solve the problem of uneven particle size of products, Achieve uniform particle size and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

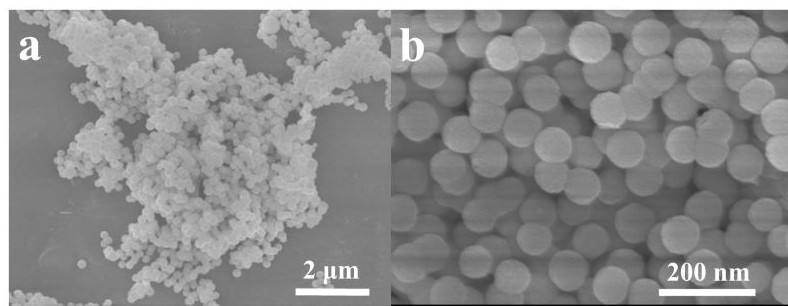

[0021] (1) Accurately weigh 2.17 g Ce(NO3)•6H2O, 3.60 g urea, and 1.00 g PVP-K30, respectively add deionized water and stir to dissolve, mix the solutions and stir for 20 minutes;

[0022] (2) Transfer the mixed solution into a polytetrafluoroethylene-lined stainless steel autoclave, raise the temperature to 100 °C, and react for 9 hours to obtain a white precipitate;

[0023] (3) After natural cooling, centrifuge the white precipitate, wash it alternately with deionized water and absolute ethanol several times, and dry it at 80 °C;

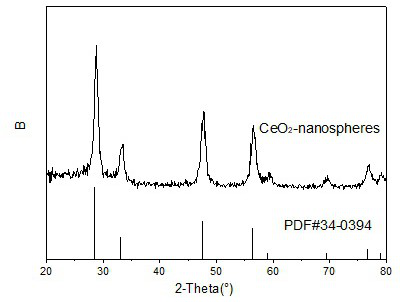

[0024] (4) The dried product was calcined at 450 °C for 4 hours to obtain a light yellow solid powder.

Embodiment 2

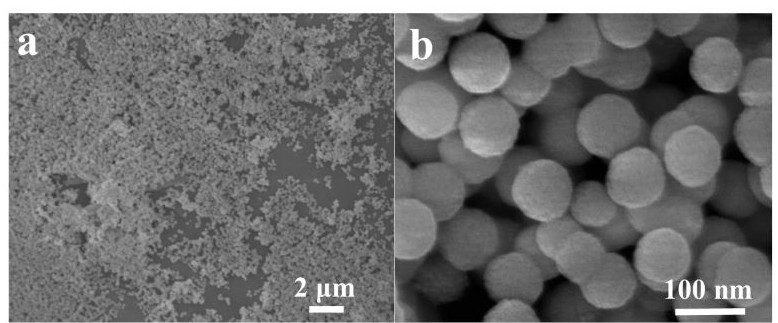

[0026] (1) Accurately weigh 2.17g Ce(NO3)•6H2O, 3.60g urea, and 1.00g PVP-K30, add deionized water and stir to dissolve, mix the solutions and stir for 20 minutes;

[0027] (2) Transfer the mixed solution into a polytetrafluoroethylene-lined stainless steel autoclave, heat up to 100 °C, and react for 10 hours to obtain a white precipitate;

[0028] (3) After natural cooling, centrifuge the white precipitate, wash it alternately with deionized water and absolute ethanol several times, and dry it at 80 °C;

[0029] (4) The dried product was calcined at 450 °C for 4 hours to obtain a light yellow solid powder.

Embodiment 3

[0031] (1) Accurately weigh 2.17 g Ce(NO3)•6H2O, 3.60 g urea, and 0.80 g PVP-K30, respectively add deionized water and stir to dissolve, mix the solutions and stir for 20 minutes;

[0032] (2) Transfer the mixed solution into a polytetrafluoroethylene-lined stainless steel autoclave, heat up to 100 °C, and react for 10 hours to obtain a white precipitate;

[0033] (3) After natural cooling, centrifuge the white precipitate, wash it alternately with deionized water and absolute ethanol several times, and dry it at 80 °C;

[0034] (4) The dried product was calcined at 450 °C for 4 hours to obtain a light yellow solid powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com