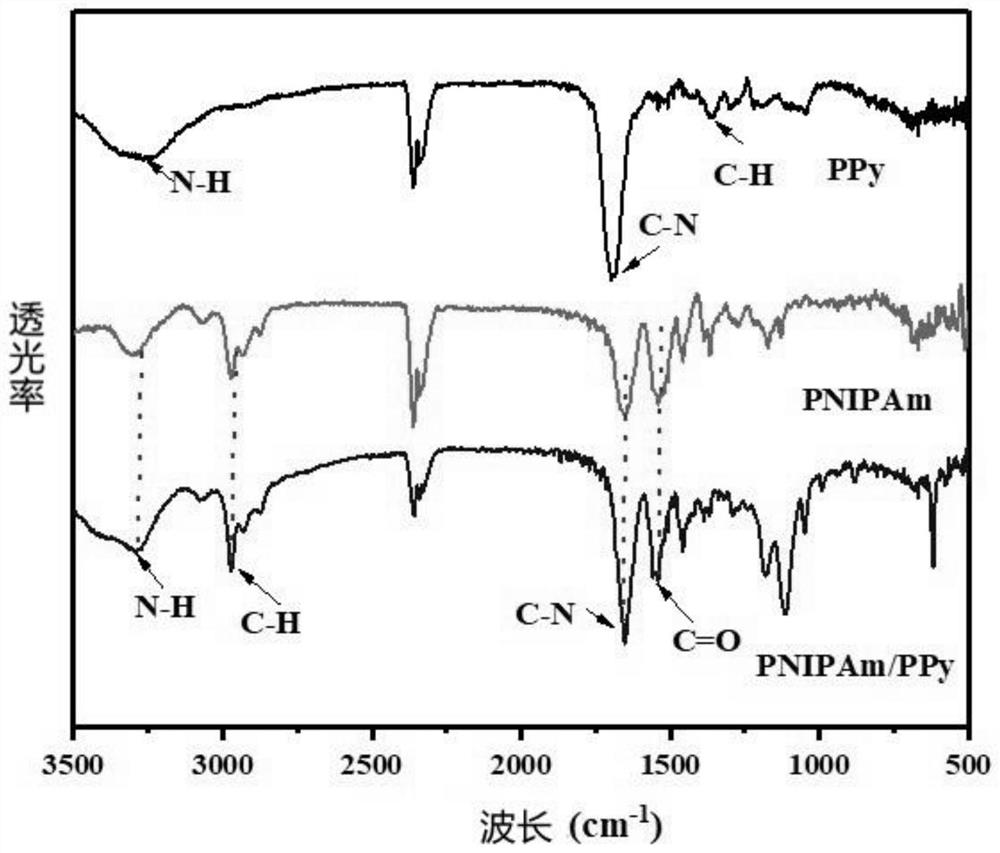

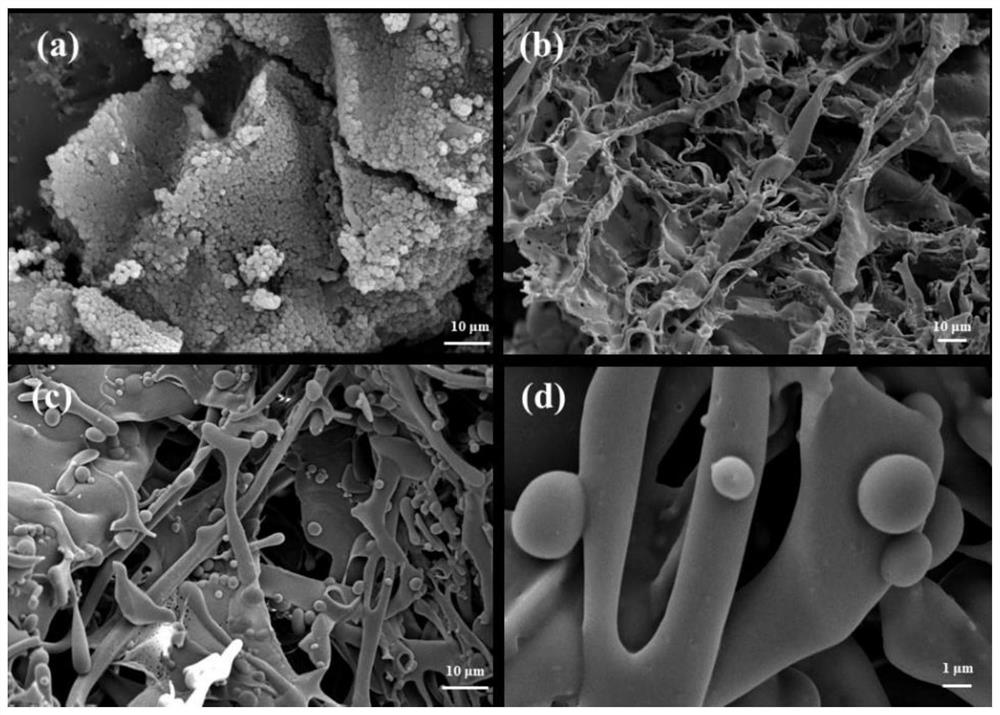

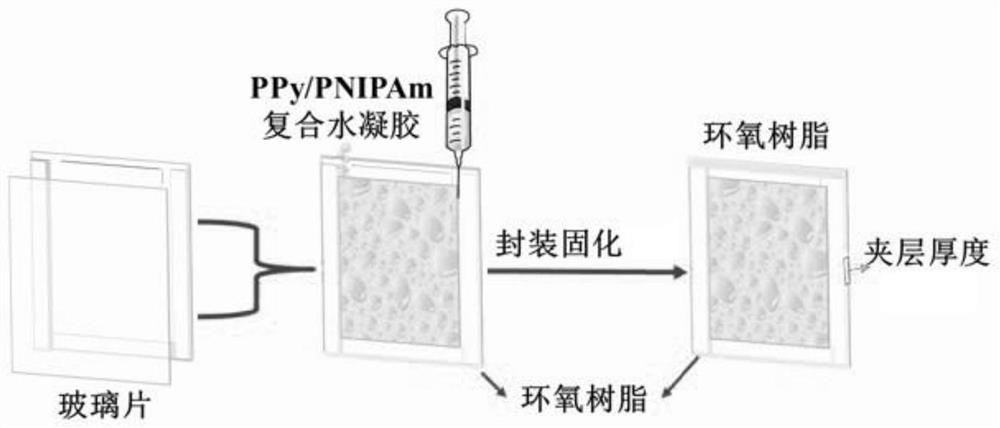

PNIPAm/PPy composite hydrogel as well as preparation method and application thereof

A composite hydrogel and hydrogel technology, applied in chemical instruments and methods, color-changing fluorescent materials, etc., can solve the problems of affecting application, slow response speed, etc., and achieve the effect of low cost, good stability, and excellent light amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of PNIPAm hydrogel:

[0030] Dissolve 0.02 g of polyvinylpyrrolidone (PVP) with a molecular weight of 58000 in 50 mL of pure water, transfer to a 250 mL three-neck flask, stir at 35 °C for 60 min to form stable micelles, and stir at 60 °C under an inert atmosphere Add 1g of PNIPAm and 0.01g of cross-linking agent N, N'-methylenebis(acrylamide) (BIS), stir evenly, raise the temperature to 60°C, and add 0.02g of initiator potassium persulfate (KPS) after the temperature stabilizes, After stirring at 60°C for 4 h, the PNIPAm hydrogel was obtained by natural cooling to room temperature, and the solid PNIPAm hydrogel was obtained by vacuum freeze-drying.

[0031] (2) Preparation of soluble PPy solution:

[0032] Dissolve 0.2 g of PVP with a molecular weight of 58,000 into 50 mL of pure water, stir evenly to form micelles, transfer to a 250 mL single-necked flask, add 0.69 mL of pyrrole and 2.7 g of KPS to the PVP solution, and place in an ice-water bath (<5 ...

Embodiment 2

[0039] (1) Dissolve 0.05 g of PVP with a molecular weight of 58,000 into 50 mL of pure water, stir at 40°C for 30 min to form stable micelles, and stir at 65°C under N 2 Add 0.8 g of PNIPAm and 0.016 g of cross-linking agent BIS under the atmosphere, stir evenly, heat up to 60°C, add 0.032 g of initiator KPS after the temperature is stable, heat and stir at 60°C for 6 h, stop the reaction, and cool naturally To room temperature to obtain PNIPAm hydrogel, vacuum freeze-drying to obtain solid PNIPAm;

[0040] (2) Dissolve 0.5 g of PVP with a molecular weight of 58,000 into 50 mL of pure water, stir evenly to form micelles, add 0.69 mL of pyrrole and 2.25 g of KPS to the mixed solution, and react in an ice-water bath (<5°C) for 3 After h, the soluble PPy solution was obtained, and the PPy powder was obtained by vacuum freeze-drying.

[0041] (3) Add 10 mL of the PPy solution prepared in step (2) to 50 mL of the PNIPAm hydrogel obtained in step (1), stir ultrasonically for 0.5 h ...

Embodiment 3

[0044] (1) Dissolve 0.1 g of PVP with a molecular weight of 58,000 into 50 mL of pure water, stir at 50°C for 30 min to form stable micelles, and stir at 70°C under N 2 Add 0.5 g NIPAm and 0.005 g cross-linking agent BIS under the atmosphere, stir evenly, raise the temperature to 70°C, add 0.02g initiator KPS after the temperature stabilizes, heat and stir at 70°C for 5 hours, stop the reaction, and cool naturally The PNIPAm hydrogel was obtained at room temperature, and the solid PNIPAm was obtained by vacuum freeze-drying. ;

[0045] (2) Dissolve 0.8 g of PVP with a molecular weight of 58,000 into 50 mL of pure water, stir evenly to form micelles, add 0.35 mL of pyrrole and 1.85 g of KPS, and react in an ice-water bath (<5°C) for 1 h to obtain a soluble PPy solution , vacuum freeze-drying to obtain PPy powder;

[0046] (3) Add 10 mL of the PPy solution prepared in step (2) to 100 mL of the PNIPAm hydrogel obtained in step (1), stir ultrasonically for 1 h at low temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com