Method for dyeing black cashmere fiber or fabric by using natural plant pigment

A technology of natural plant pigments and cashmere fibers, which is applied in the field of dyeing black cashmere fibers or fabrics with natural plant pigments, can solve the problems of dyeing cashmere fibers or fabrics into environmentally friendly black, and achieve the effect of high added value and less pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

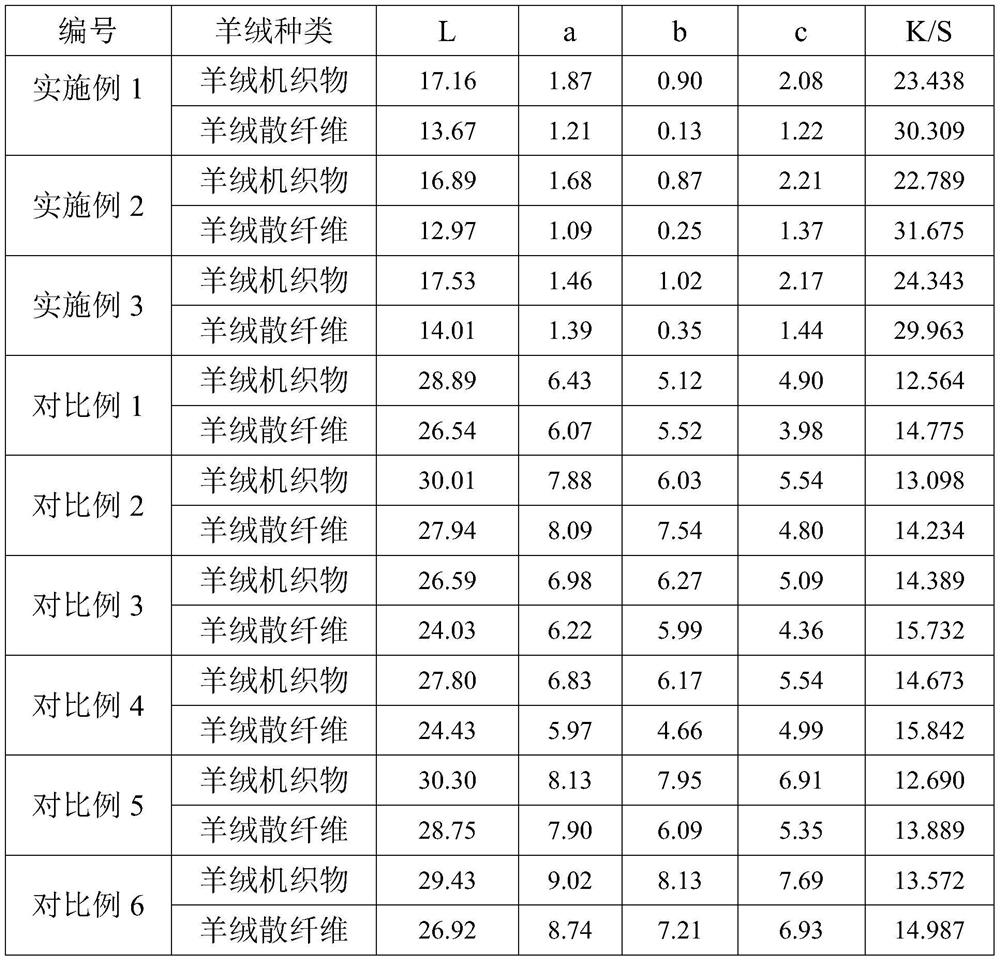

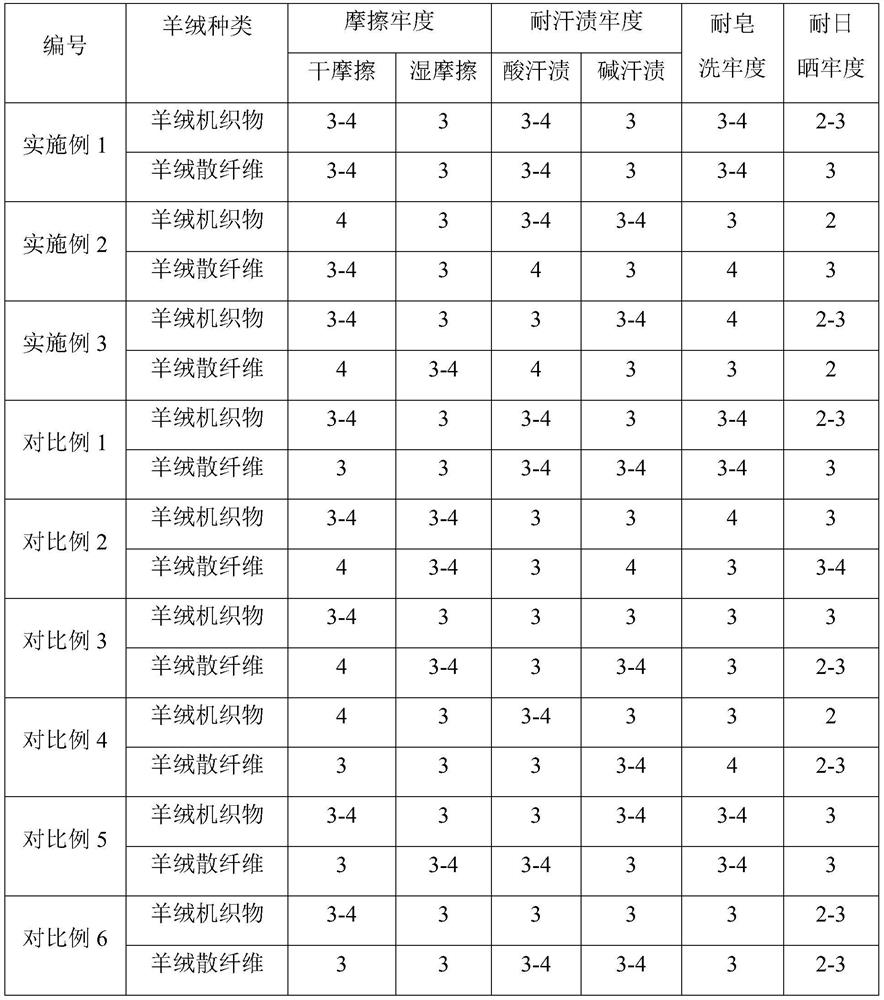

Examples

Embodiment 1

[0102](1) Extract walnut green peel pigment, gallnut pigment, yam yam pigment and green tea tea pigment respectively;

[0103] (2) Carry out pre-dyeing pretreatment to cashmere fiber or fabric by adopting pre-dyeing pre-treatment liquid, wherein, contain hydrogen peroxide solution, penetrant, acid protease and anionic surfactant in the pre-treatment liquid;

[0104] (3) According to the liquor ratio of 1:20, add walnut green skin pigment, gallnut pigment, yam pigment, green tea tea pigment, penetrating agent and non-ionic surfactant to the cashmere fiber or fabric after pre-dyeing pretreatment, carry out dyeing;

[0105] (4) Washing, soaping, washing and drying the dyed cashmere fibers or fabrics;

[0106] Wherein, the extracting method of walnut green peel pigment comprises the following steps:

[0107] A1. Peeling fresh walnuts to obtain fresh walnut green peels, drying the fresh walnut green peels at 98° C. and then pulverizing them to obtain walnut green peel powders;

...

Embodiment 2

[0135] (1) Extract walnut green peel pigment, gallnut pigment, yam yam pigment and green tea tea pigment respectively;

[0136] (2) Carry out pre-dyeing pretreatment to cashmere fiber or fabric by adopting pre-dyeing pre-treatment liquid, wherein, contain hydrogen peroxide solution, penetrant, acid protease and anionic surfactant in the pre-treatment liquid;

[0137] (3) According to the liquor ratio of 1:15, add walnut green skin pigment, gallnut pigment, yam pigment, green tea tea pigment, penetrating agent and non-ionic surfactant to the cashmere fiber or fabric after pre-dyeing pretreatment, carry out dyeing;

[0138] (4) Washing, soaping, washing and drying the dyed cashmere fibers or fabrics;

[0139] Wherein, the extracting method of walnut green peel pigment comprises the following steps:

[0140] A1. Peeling fresh walnuts to obtain fresh walnut green peels, drying the fresh walnut green peels at 103° C. and then pulverizing them to obtain walnut green peel powders; ...

Embodiment 3

[0168] (1) Extract walnut green peel pigment, gallnut pigment, yam yam pigment and green tea tea pigment respectively;

[0169] (2) Carry out pre-dyeing pretreatment to cashmere fiber or fabric by adopting pre-dyeing pre-treatment liquid, wherein, contain hydrogen peroxide solution, penetrant, acid protease and anionic surfactant in the pre-treatment liquid;

[0170] (3) According to the bath ratio of 1:10, add walnut green skin pigment, gallnut pigment, yam pigment, green tea tea pigment, penetrating agent and nonionic surfactant to the cashmere fiber or fabric after dyeing pretreatment, carry out dyeing;

[0171] (4) Washing, soaping, washing and drying the dyed cashmere fibers or fabrics;

[0172] Wherein, the extracting method of walnut green peel pigment comprises the following steps:

[0173] A1. Peeling fresh walnuts to obtain fresh walnut green peels, drying the fresh walnut green peels at 95° C. and then pulverizing them to obtain walnut green peel powders;

[0174...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com