Corrosion prevention arrangement structure and method of heating surface of waste incineration boiler

A technology of waste incineration and layout structure, which is applied in the combustion method, incinerator, combustion type, etc., can solve the problems of poor surface flatness, large consumption of nickel-based alloys, and high cost of anti-corrosion layer layout, and achieves accelerated work. The effect of quality circulation, improving anti-corrosion performance, economical and effective anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

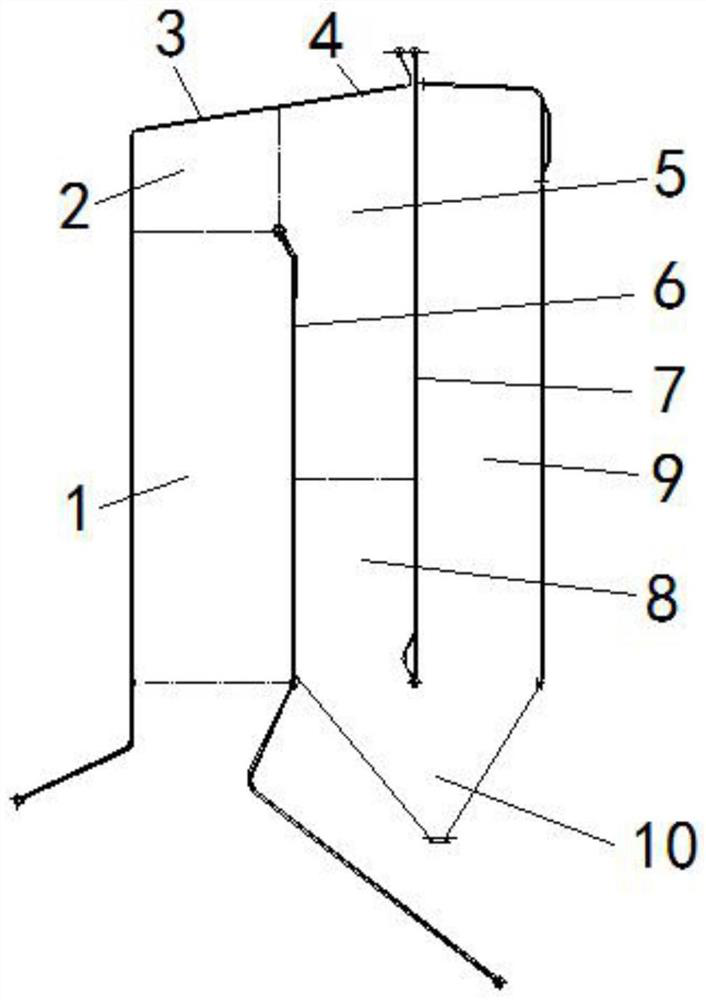

[0049] This embodiment provides an anti-corrosion layout structure of the heating surface of the waste incineration boiler, the structure of the boiler flue is as follows figure 1 As shown, it includes a flue, a second flue and a third flue arranged in sequence along the flue gas flow direction, the flue gas flows from bottom to top along the first flue, and flows from top to bottom along the second flue, It flows from bottom to top along the three flues, and the bottom of the second flue and the third flue communicate with the ash hopper (10); the anti-corrosion layout structure of the heating surface of the boiler is specifically as follows:

[0050] A refractory pouring anticorrosion layer is arranged on the heating surface of the lower part (1) of the flue;

[0051] The heating surface of the upper part of the first flue (2) and the heating surface of the side wall of the second flue (5) where the smoke temperature is higher than 750°C are arranged with a surfacing anti-co...

Embodiment 2

[0057] The surfacing, laser cladding and micro-fusion welding techniques implemented in Example 1 are compared and analyzed, and the results are shown in Table 1:

[0058] Table 1 Comparison of three anti-corrosion coating technologies

[0059]

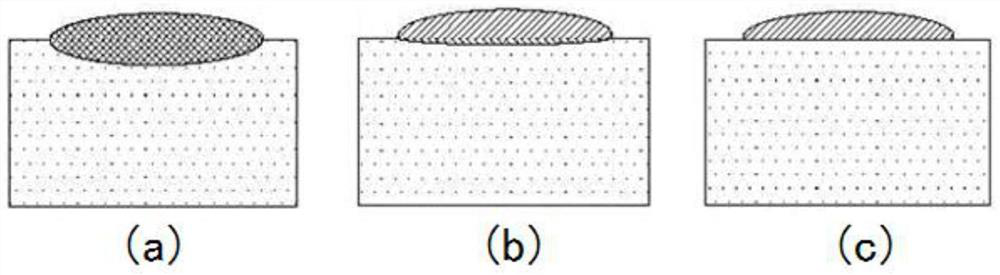

[0060] When surfacing welding, laser cladding and micro-fusion welding technologies are used to arrange the anti-corrosion layer, its penetration on the base material is as follows: figure 2 as shown, figure 2 It is a schematic diagram of the structure of the anti-corrosion layer formed by surfacing, laser cladding and micro-fusion welding provided by the embodiment of the present invention, wherein (a) is surfacing welding, (b) is laser cladding, and (c) is micro-fusion welding form. It can be seen that the penetration depth of the alloy layer in the form of surfacing welding is the largest, the penetration depth of the alloy layer in the form of micro-fusion welding is the smallest, and the penetration depth of the alloy laye...

Embodiment 3

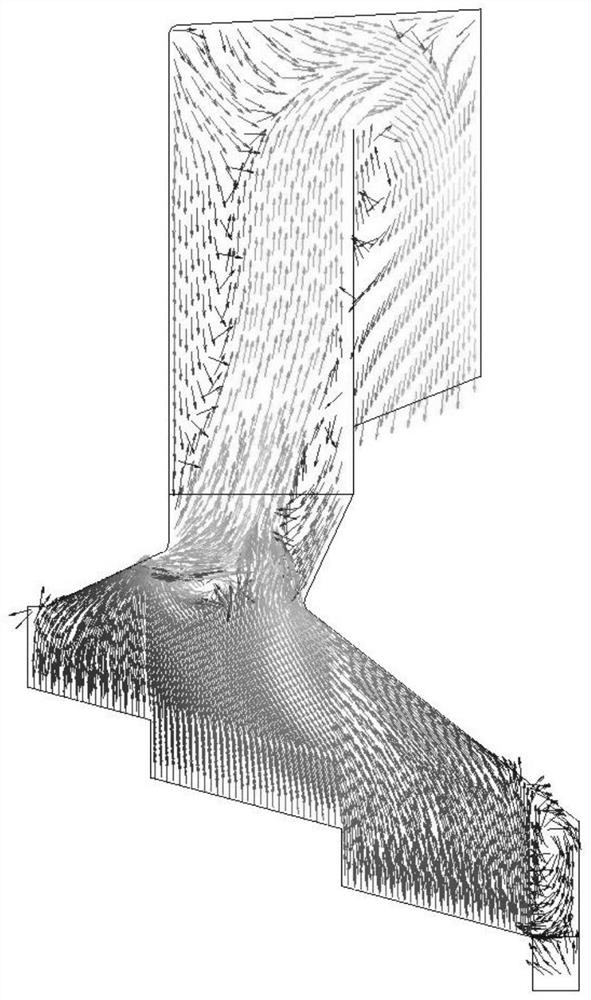

[0063] The flue gas flow field in the water wall area of the waste incineration boiler in embodiment 1 is simulated, and the results are as follows image 3 as shown, image 3 It is the vector diagram of the flue gas flow field in the water wall area of the waste incineration boiler provided by the embodiment of the present invention. pass image 3 It can be clearly seen that the erosion of flue gas on the ceiling of the first flue, the ceiling of the second flue and the back wall of the second flue is the most serious.

[0064] According to the simulation results of the above-mentioned flue gas flow field, for the upper part of the first flue, the ceiling of the first flue, the ceiling of the second flue, the area where the smoke temperature of the side wall of the second flue is higher than 750 ° C, and the area where the smoke temperature of the front wall of the second flue is higher than 750 ° C For the anticorrosion layer on the heating surface in the area where th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com