Static TBMEPB cutter wear back analysis method based on beam-spring unit

A spring unit, tool wear technology, applied in instrumentation, geometric CAD, design optimization/simulation, etc., can solve problems such as complex rock mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Embodiment, a kind of static TBM&EPB tool wear back analysis method based on beam-spring unit, comprises the following steps:

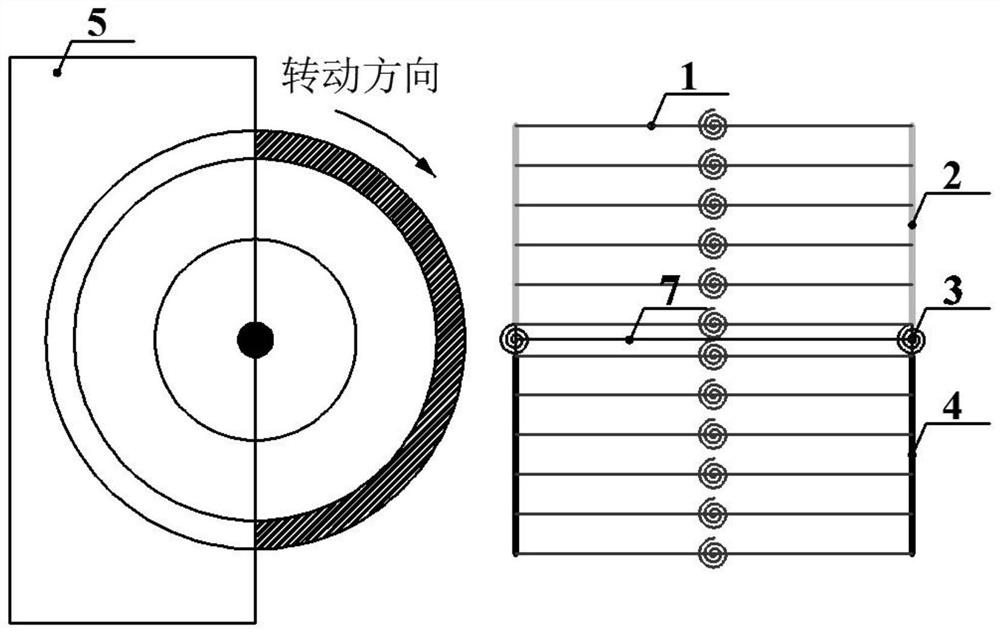

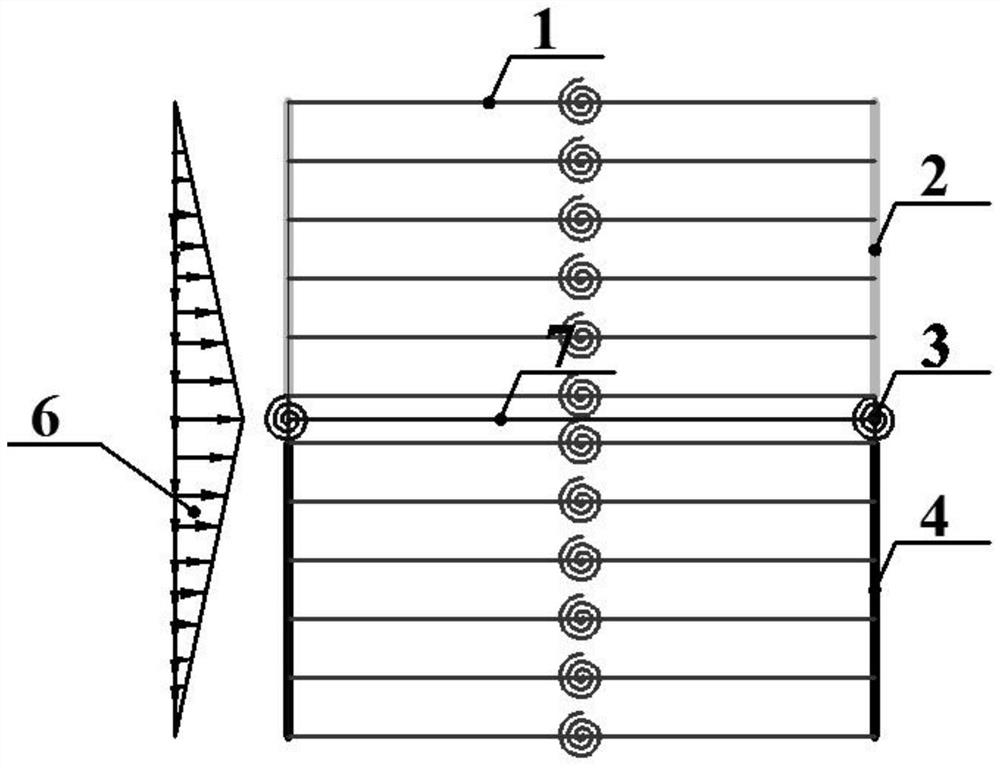

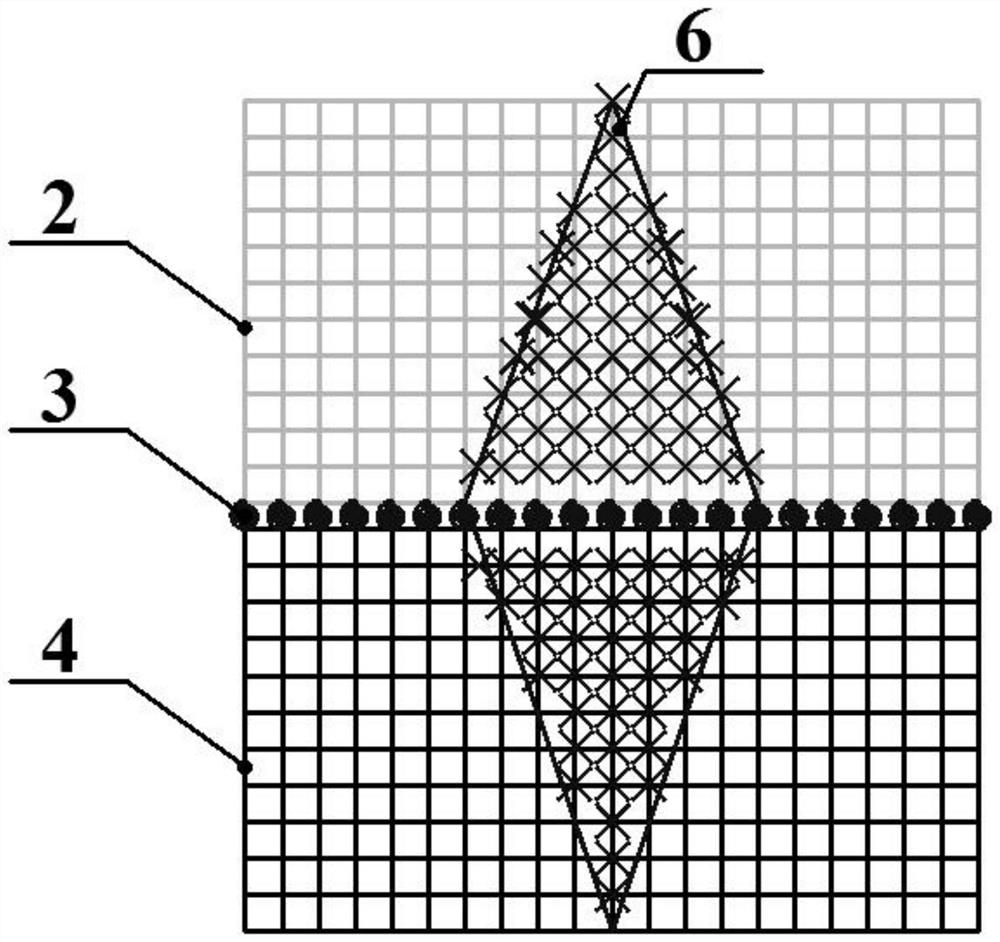

[0026] Step A. Construct a beam-spring calculation model: restore the surface of the cut rock mass through a beam unit with better mechanical properties, and at the same time connect the surface of the rock mass adjacent to the two layers through the connecting spring and the interlayer spring to simulate and restore the shear and deformation of the rock mass during the cutting process;

[0027] Step B, applying curved surface springs and reasonable boundaries on the basis of the beam-spring calculation model constructed above, and then applying the cutting stress of the tool acting on the rock mass to the beam-spring calculation model;

[0028] Step C, based on the nonlinear analysis of finite element, calculate the axial stress, shear stress, torsional stress, displacement, deformation, rock reaction force and a series of factors generated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com