Synthetic furnace base with temperature control protection and automatic cleaning functions

A technology of automatic cleaning and temperature control protection, applied in chemical instruments and methods, control/regulation processes, chemical/physical/physical-chemical processes, etc. Strong thermal shock ability and good overall structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

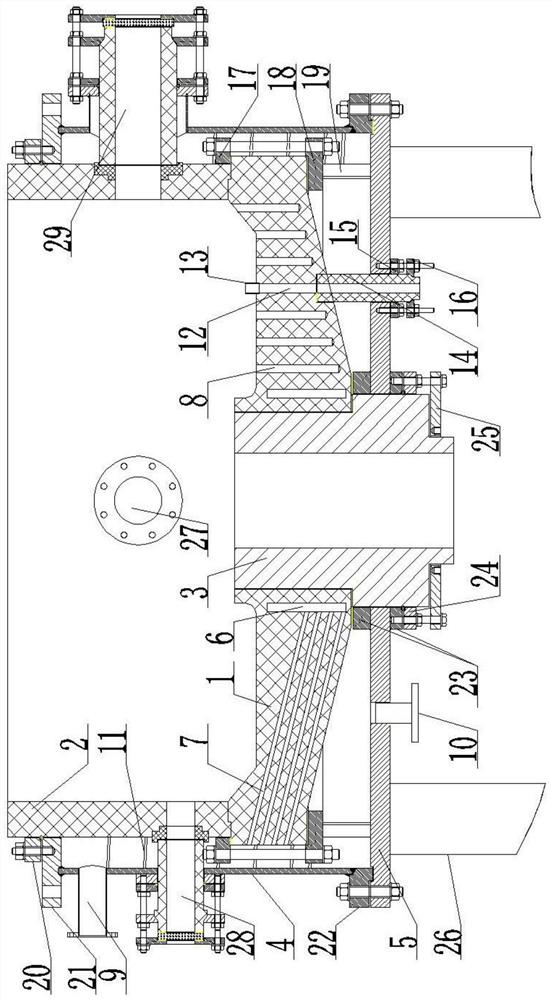

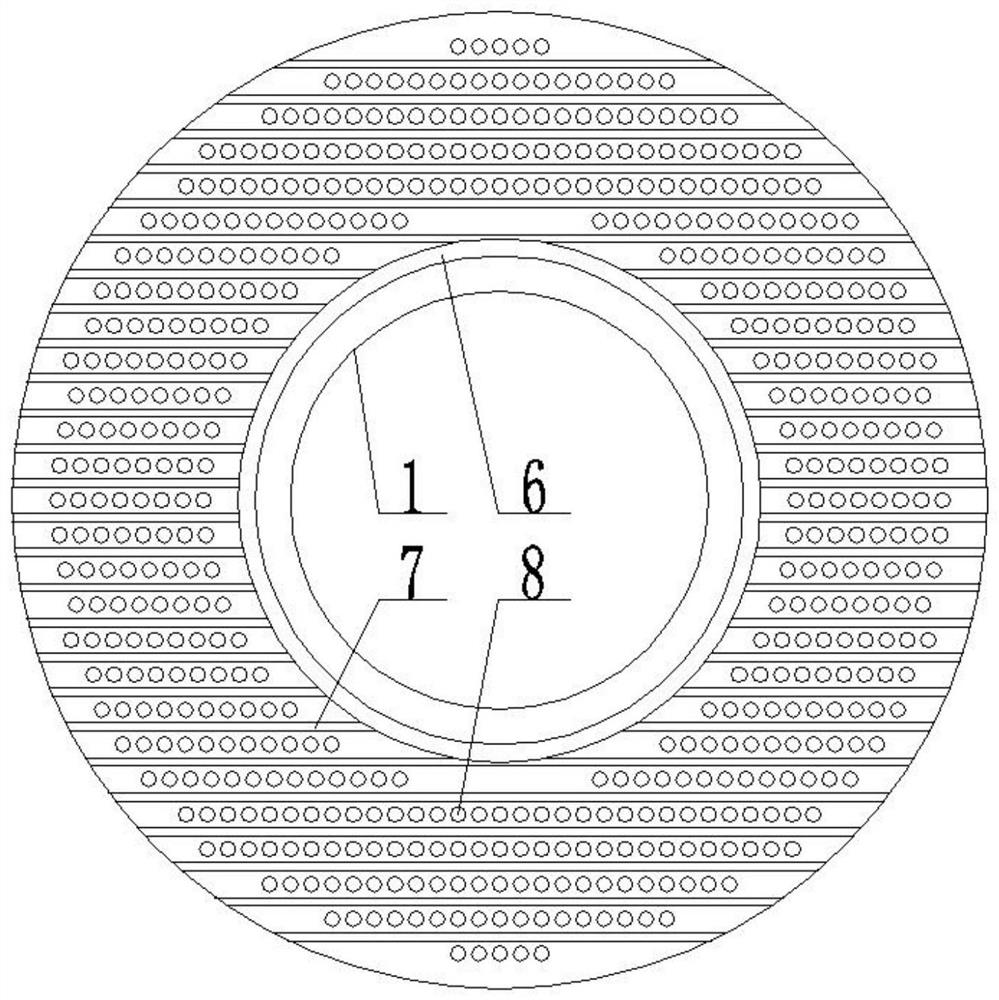

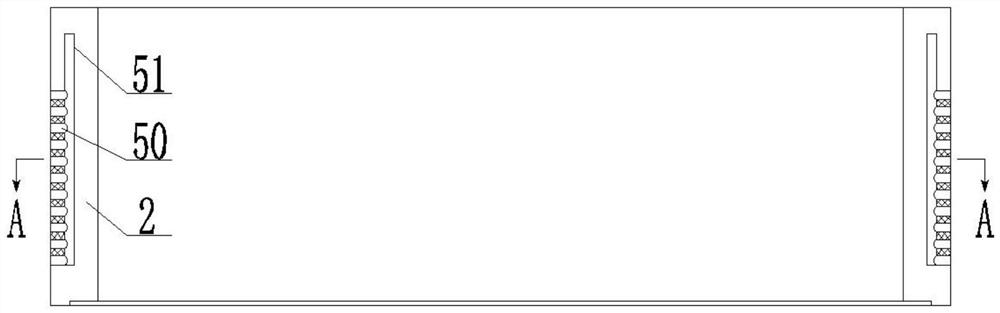

[0040] Embodiment of the present invention: a synthesis furnace base with temperature control protection and automatic cleaning function, as attached Figure 1-7 As shown, it includes a butterfly-shaped graphite head 1, a graphite cylinder 2 coaxially placed on the top of the butterfly-shaped graphite head 1, a concentric graphite manhole casing 3 built into the butterfly-shaped graphite head 1, and a butterfly-shaped graphite head 1 and The graphite cylinder 2 is inserted into the metal cylinder 4, the top of the metal cylinder 4 is sealed and connected with the outer wall above the graphite cylinder 2, the bottom of the metal cylinder 4 is fixedly connected with the metal cover 5, and the metal cover 5 is fixedly sleeved on the metal On the outer wall of cylinder 4.

[0041] During use, the nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com