Medium-carbon boron-containing steel and controlled rolling and controlled cooling method for online normalizing treatment

A technology of normalizing treatment, controlled rolling and controlled cooling, which is applied in the direction of heat treatment process control, heat treatment furnace, heat treatment equipment, etc., can solve the problems of restricting mass production and application of products, increasing production costs, and low production efficiency, so as to improve product competition The effect of speeding up the production cycle and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The cross-sectional size of the selected billet is 240mm×240mm; according to the mass percentage, the chemical composition of the billet of the medium-carbon boron-containing steel includes: C 0.38%; Si 0.25%; Mn 0.86%; Al 0.032%; B 0.0017%; Ti 0.047% ; P0.013%; S 0.005%; Cr 0.14%; Ni 0.03%; Mo 0.02%; Cu 0.02%;

[0044] Heating step: the heating temperature of the billet entering the heating furnace is 1140-1160°C, and the total heating time is 142min;

[0045] Rough rolling step: the inlet temperature of the rough rolling unit is 1038°C;

[0046] Finishing step: use the reducing and sizing finishing mill, and the inlet temperature of the finishing mill is 795°C;

[0047] Water-piercing cooling step: The finished steel rolled by the reducing and sizing finishing mill is cut by flying shear and then sprayed with water to cool the finished steel.

[0048] Cooling bed slow cooling step: carried out in a step-by-step cooling bed, the cooling rate of the finished steel is ...

Embodiment 2

[0052] According to mass percentage, the chemical composition of the medium-carbon boron-containing steel billet includes: C 0.38%; Si 0.25%; Mn0.84%; Al 0.028%; B 0.0020%; Ti 0.045%; P 0.012%; S 0.008%; Cr 0.12%; Ni0.02%; Mo 0.03%; Cu 0.03%; the rest is Fe and unavoidable impurities; the cross-sectional size of the selected billet is 240mm×240mm.

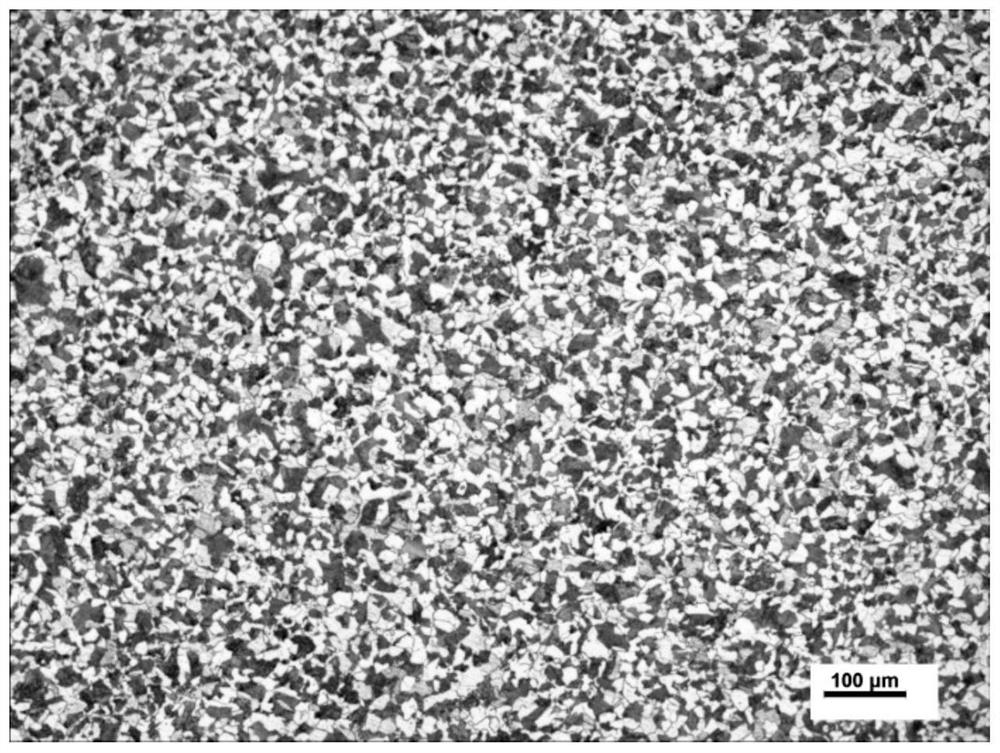

[0053] The steps of the controlled rolling and controlled cooling method suitable for on-line normalizing treatment of medium-carbon boron-containing steel are as in Example 1, wherein the parameters of each step of the controlled-rolling and controlled-cooling method suitable for on-line normalizing treatment of medium-carbon boron-containing steel are shown in Table 1. The finished product steel section 1 / 2 place hardness after the step of embodiment 2 is processed is 212 / 215HBW; Actual grain size is 9 grades; figure 2 As shown, the banded structure is grade 1.5.

[0054] Table 1 is each step parameter of embodiment 1 and embod...

Embodiment 3-5

[0057] The chemical composition of the medium-carbon boron-containing steel slabs of Examples 3-5 is the same as that of Example 1.

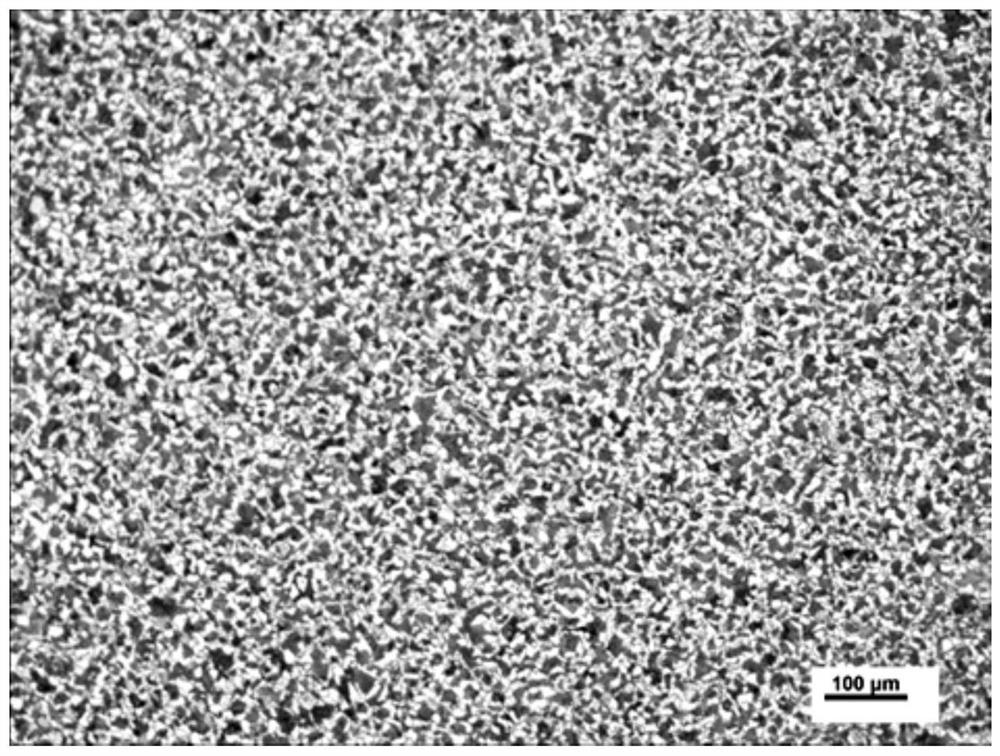

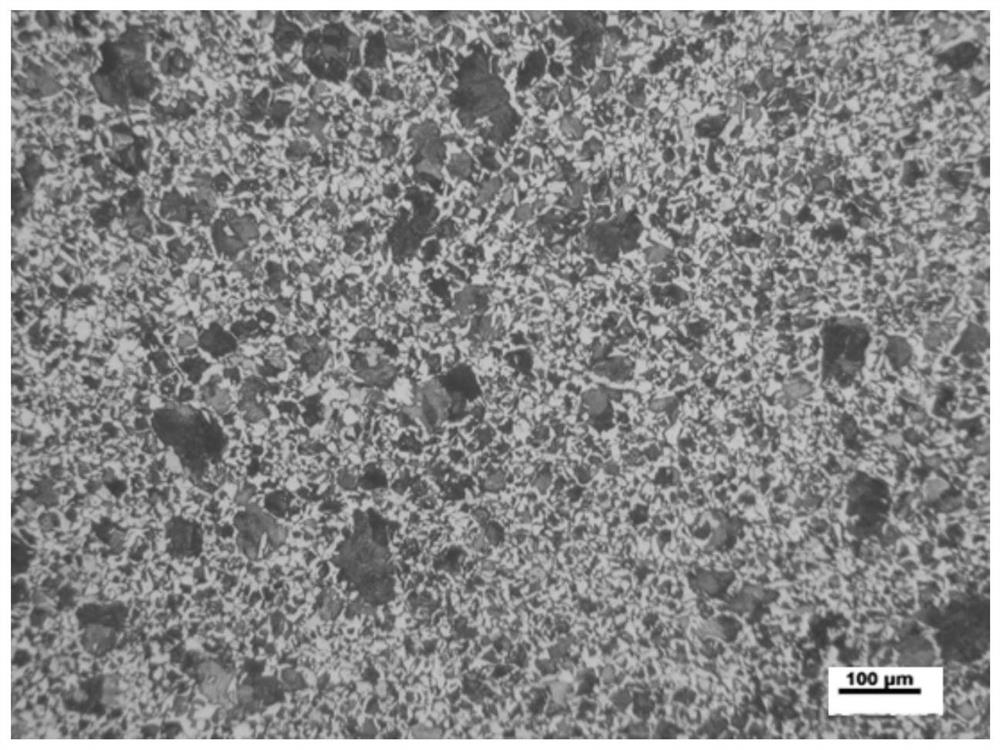

[0058] Heating in embodiment 3-5, rough rolling, finishing rolling, piercing water cooling, the parameters of cooling bed slow cooling each step are as shown in table 2, the performance of finished steel comprises hardness at 1 / 2R place, grain size and strip shape The organizational level is also shown in Table 2.

[0059] Table 2 is each step parameter of embodiment 3-5 and the performance of gained steel

[0060]

[0061]

[0062] It can be known from Table 2 that the hardness at 1 / 2R of the steel obtained in Examples 3-5 is 202-214HBW, the grain size is 8-8.5, and the band structure is 1.5-2.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com