Mineral wool production device and method for plasma hazardous waste ash melting system

A production device and production method technology, applied in glass production, furnace type, induction heating, etc., can solve the problems of high energy consumption, poor process stability, high raw material cost, etc., to achieve increased output, improved operating efficiency, and improved controllable dimensions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

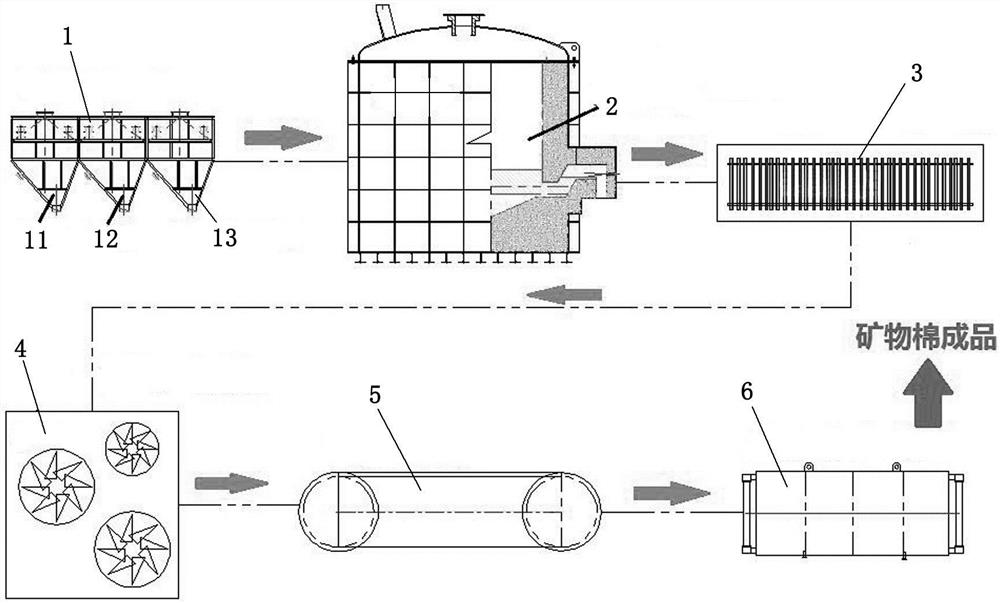

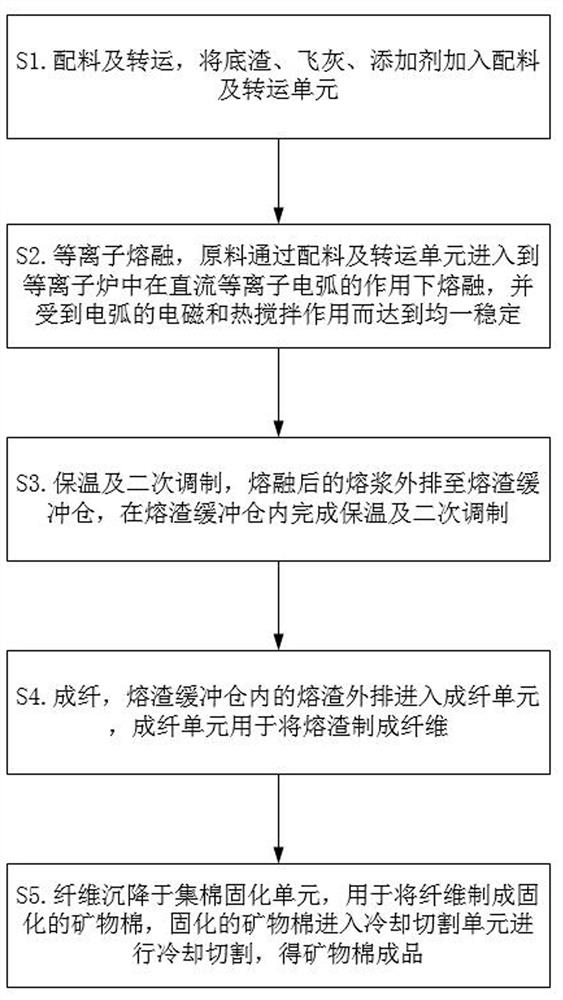

[0032] A mineral wool production device for a plasma hazardous waste ash melting system, see figure 1 , the mineral wool production device includes a sequentially connected batching and transfer unit 1, a plasma furnace 2 (plasma hazardous waste ash melting furnace), a slag buffer bin 3, a fiber forming unit 4, and a cotton collection and solidification unit 5 from upstream to downstream And the cooling and cutting unit 6, the batching and transfer unit 1 is used to transfer the fly ash 11, bottom slag 12 and additive 13 to the inlet of the plasma furnace 2, and the molten slurry at the outlet of the plasma furnace 2 is discharged to the slag buffer Warehouse 3, the molten slurry is kept warm and re-modulated in the slag buffer warehouse 3, the slag in the slag buffer warehouse 3 is discharged into the fiber forming unit 4, and the fiber forming unit 4 is used to make the slag into fibers, The fibers are settled in the cotton collecting and solidifying unit 5 for making the fi...

Embodiment 2

[0045] A mineral wool production device used in a plasma hazardous waste ash melting system, the mineral wool production device includes a sequentially connected batching and transfer unit 1, a plasma furnace 2, a slag buffer bin 3, and a fiber forming unit from upstream to downstream 4. Cotton collection and solidification unit 5 and cooling and cutting unit 6. The batching and transfer unit 1 is used to transfer fly ash 11, bottom slag 12 and additive 13 to the feed port of plasma furnace 2, and the melting process at the discharge port of plasma furnace 2. The slurry is discharged to the slag buffer bin 3, where the molten slurry is kept warm and re-modulated in the slag buffer bin 3, and the slag in the slag buffer bin 3 is discharged into the fiber forming unit 4, and the fiber forming unit 4 is used for The slag is made into fibers, and the fibers are settled in the cotton collection and solidification unit 5 for making the fibers into solidified mineral wool, and the sol...

Embodiment 3

[0053] A mineral wool production device used in a plasma hazardous waste ash melting system, the mineral wool production device includes a sequentially connected batching and transfer unit 1, a plasma furnace 2, a slag buffer bin 3, and a fiber forming unit from upstream to downstream 4. Cotton collection and solidification unit 5 and cooling and cutting unit 6. The batching and transfer unit 1 is used to transfer fly ash 11, bottom slag 12 and additive 13 to the feed port of plasma furnace 2, and the melting process at the discharge port of plasma furnace 2. The slurry is discharged to the slag buffer bin 3, where the molten slurry is kept warm and re-modulated in the slag buffer bin 3, and the slag in the slag buffer bin 3 is discharged into the fiber forming unit 4, and the fiber forming unit 4 is used for The slag is made into fibers, and the fibers are settled in the cotton collection and solidification unit 5 for making the fibers into solidified mineral wool, and the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com