Coating device

A coating device and coating technology, which are applied to spray devices, devices for coating liquid on surfaces, coatings, etc., can solve the problem of difficulty in achieving uniform and stable thickness of insulating coatings, and insufficient precision in liquid volume control and liquid film control. , it is difficult to ensure the complete coverage of the liquid film, etc., to achieve the effect of simple structure, complete and uniform liquid film, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

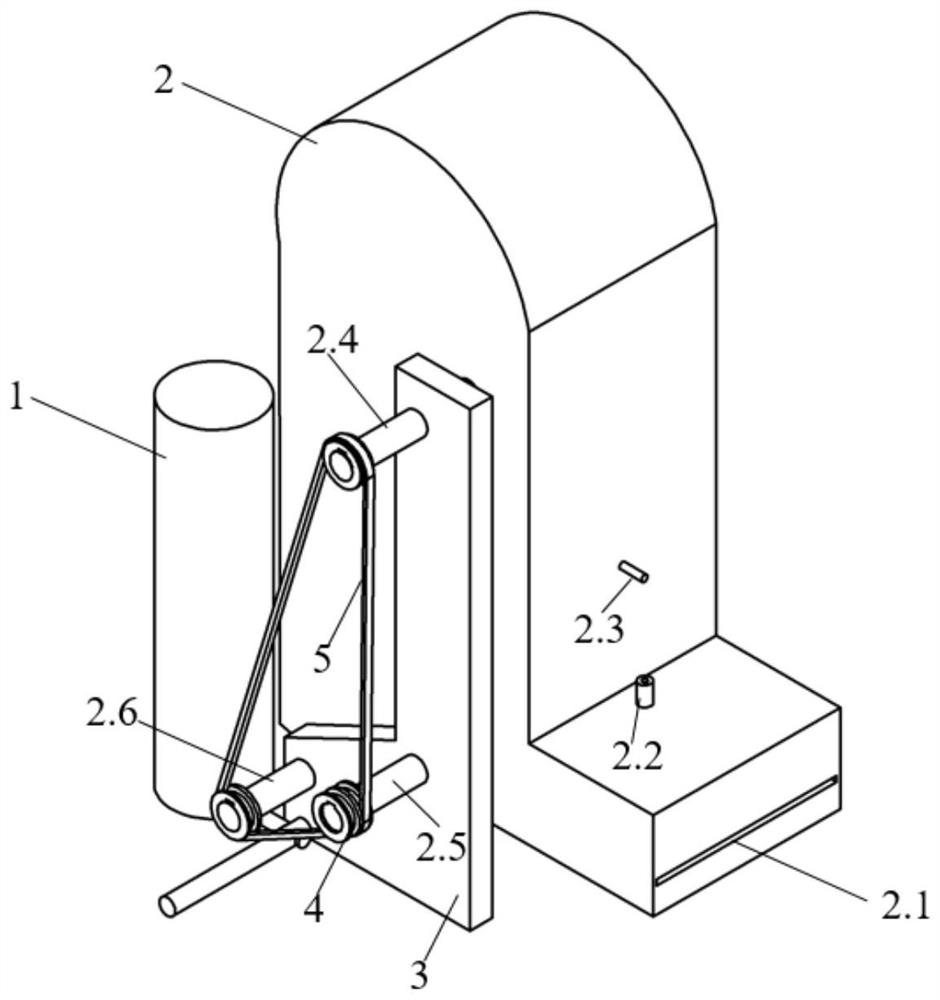

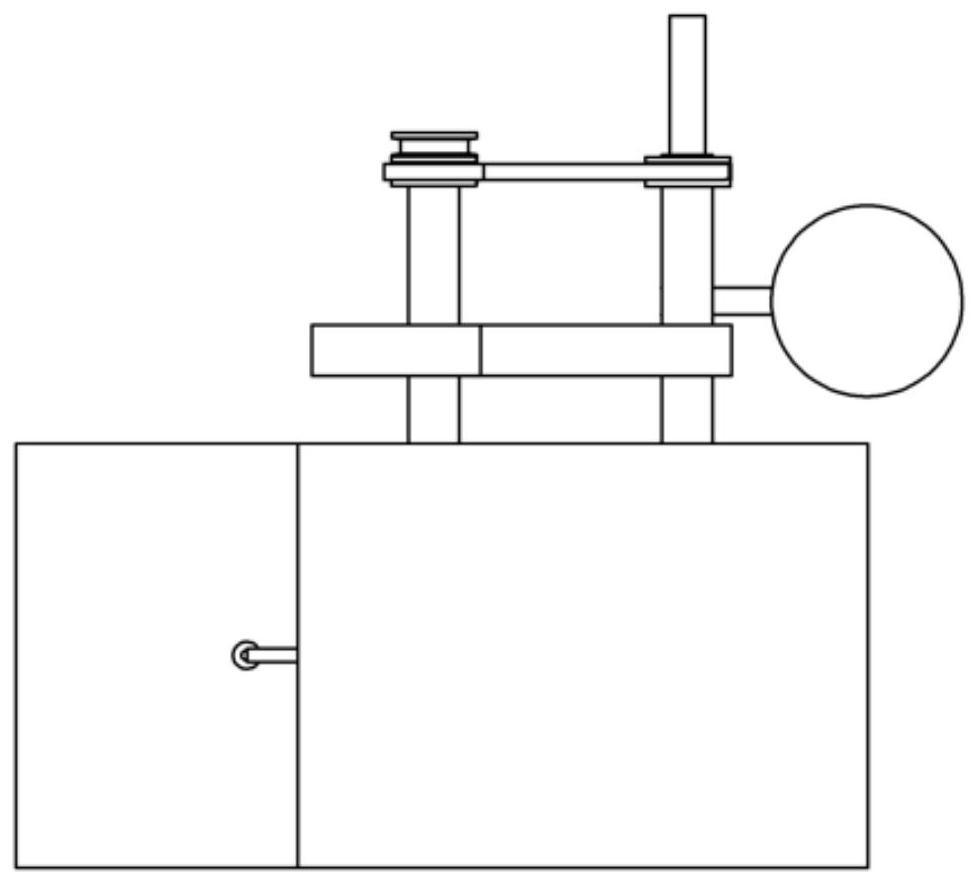

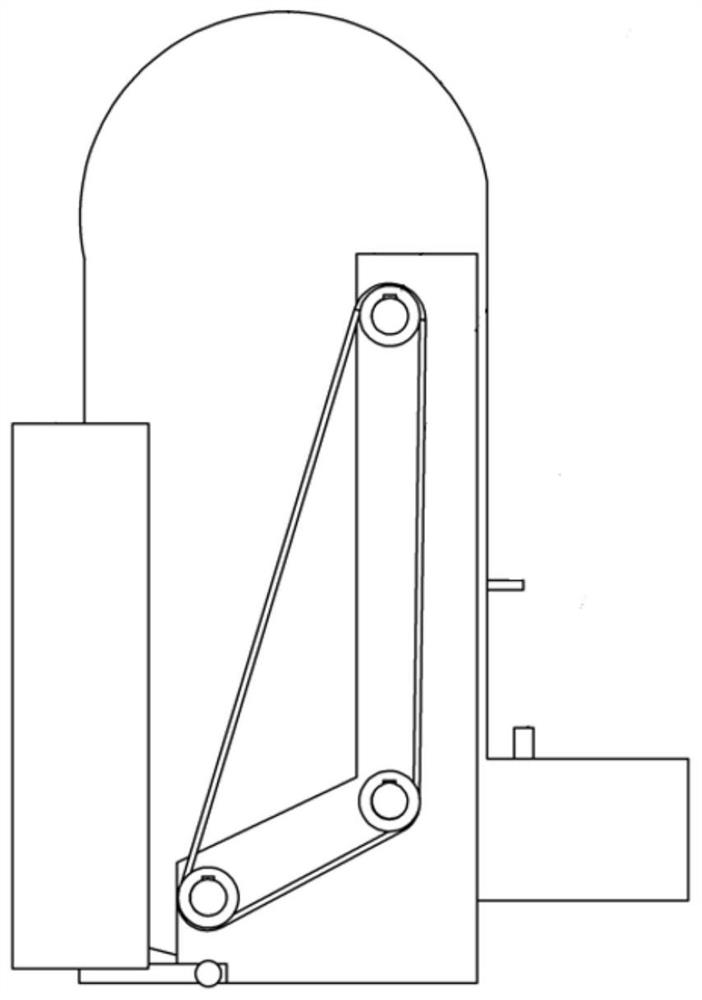

[0058] The coating operation of the nanoside coil polysilitase solution was used to use the coating apparatus of the present invention. Image 6 The sprayed manner, the strip is from the feed port 2.2 into the coating chamber 2, the nozzle 2.2 spray the insulating material solution, by passing from the lower side of the fourth rotating roller 2.8, spraying the surface of the strip through the spray head 2.2 The subsequent strip passes from the bottom of the fifth rotating roller 2.9 and is bonded to the coating belt 2.7, and the direction of movement of the strip is opposite to the motion of the coating tape 2.7, which is designed to remove excess coatings on the back of the strip. Subsequently, the strip is moved in the direction of the discharge port 2.12 to the top of the first rotational roller 2.4 and the sixth rotational roller 2.10. The coating atmosphere is nitrogen, the first rotating roller 2.4, the second rotation roller 2.5, and the third rotation roller 2.6 are 60 mm, ...

Embodiment 2

[0061] The coating operation of nano-strip modified silica sol using the coating apparatus of the present invention is selected. Figure 7 The brushing method, the insulating substance solution does not have a portion of the third rotating roller 2.6, by the first rotational roller 2.4, the second rotation roller 2.5, the third rotation roller 2.7, can be taken 2.7 itself Liquid; the strip is from the feed port 2.1 into the coating chamber 2. The strip sequentially passes below the fourth rotating roller 2.8, and the bottom of the fifth rotation roller 2.7 is fitted with the coating belt 2.7, the direction of the strip and coating In contrast to the direction of movement of 2.7, the strip is separated by the strip and the coated belt 2.7, and then the strip is above the upper side of the first rotational roller 2.4, from above the sixth rotational roller 2.10, the discharge port 2.12. Directional movement. The coating atmosphere is argon, the first rotational roller 2.4, the second...

Embodiment 3

[0066] Using the apparatus of the present invention to carry out the coating operation of the nanocrystalline strip methyl silicone resin, Figure 8 The immersion method shown, the insulating substance solution does not have a portion of the third rotating roller 2.6; the strip is from the feed port 2.1 into the coating chamber 2, the strip is divided into the lower side of the fourth rotating roller 2.9, and the fifth rotation roller 2.9 Above, the direction of the strip 2.7 is bonded, the movement direction of the strip is the same as the moving direction of the coated belt 2.7, and the strip passes below the second rotation roller 2.5, and the third rotation roller 2.6 is immersed in the liquid surface or below the liquid surface. The surface belt liquid, and then the strip moves from above the sixth rotational roller 2.10, moves in the direction of the discharge port 2.12. The coating atmosphere is dry air (relative air humidity <1%), the first rotational roller 2.4, the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com