Preparation method of environment-friendly mute floor

An environmentally friendly, flooring technology, applied in floor coverings, chemical instruments and methods, lamination, etc., to achieve strong adhesion, improve working environment, and increase efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

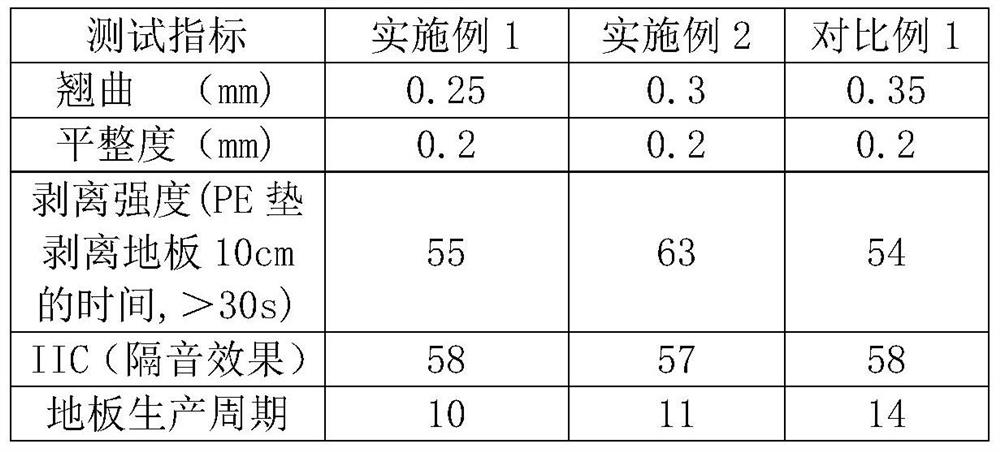

Examples

Embodiment 1

[0026] A method for preparing an environment-friendly silent floor, specifically attaching a new foamed PE cushion to the back of a hard PVC floor, specifically includes the following steps:

[0027] (1) Production of hard PVC floor semi-finished products: Weigh the raw materials in corresponding parts by weight, mix 100 parts of PVC resin, 280 parts of stone powder, 3 parts of stearic acid, 5 parts of internal lubricant, and 5 parts of impact modifier 3. Add 3 parts of coloring agent to the high-speed mixer. After setting the temperature to 110°C, mix and stir evenly at a speed of 250r / min while raising the temperature. After reaching the temperature, start cold mixing at the same time, and put the The raw material is unloaded to the cold mixer and stirred for 12 minutes; the cold-mixed material is unloaded into the storage tank, and fed into the twin-screw extruder, the temperature of the screw area is 195°C, and the temperature of the outlet mold is 185°C; the calendering te...

Embodiment 2

[0031] A method for preparing an environment-friendly silent floor, specifically attaching a new foamed PE cushion to the back of a hard PVC floor, specifically includes the following steps:

[0032] (1) Production of hard PVC floor semi-finished products: Weigh the raw materials in corresponding parts by weight, mix 110 parts of PVC resin, 350 parts of stone powder, 8 parts of stearic acid, 4 parts of internal lubricant, and 8 parts of impact modifier 1. Add 1 to 4 parts of colorant to the high-speed mixer. After setting the temperature to 110°C, mix and stir evenly at a speed of 300r / min while raising the temperature. The material in the machine is unloaded to the cold mixer and stirred for 13 minutes; the cold-mixed material is unloaded into the storage tank, and fed into the twin-screw extruder, the temperature of the screw area is 200 ° C, the temperature of the outlet mold is 190 ° C; the calendering temperature is 215 ° C , the hard PVC base material is obtained, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com