Integrated surface light-emitting structural member and manufacturing method thereof

A technology of surface luminescence and manufacturing method, which is applied in chemical instruments and methods, special decorative structures, other household appliances, etc., can solve the problems of high requirements, high price, low product yield and other problems, and achieves simple structure and manufacturing process. Occupy design space, rich luminous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

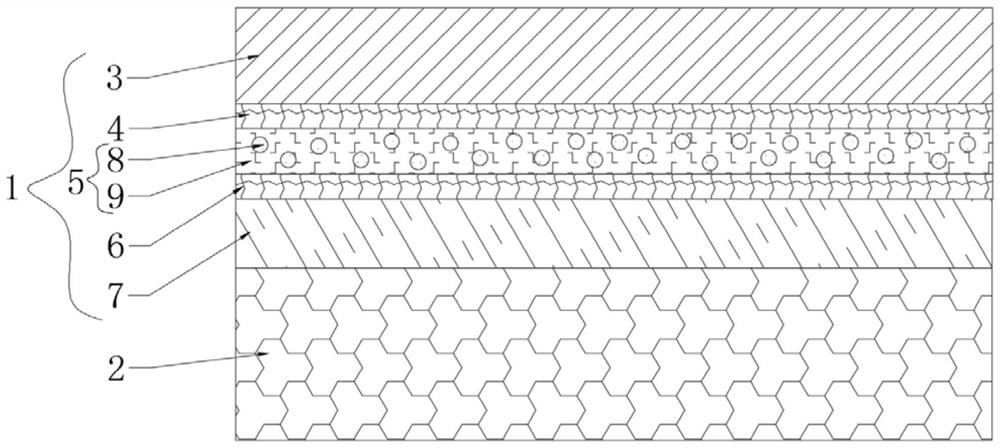

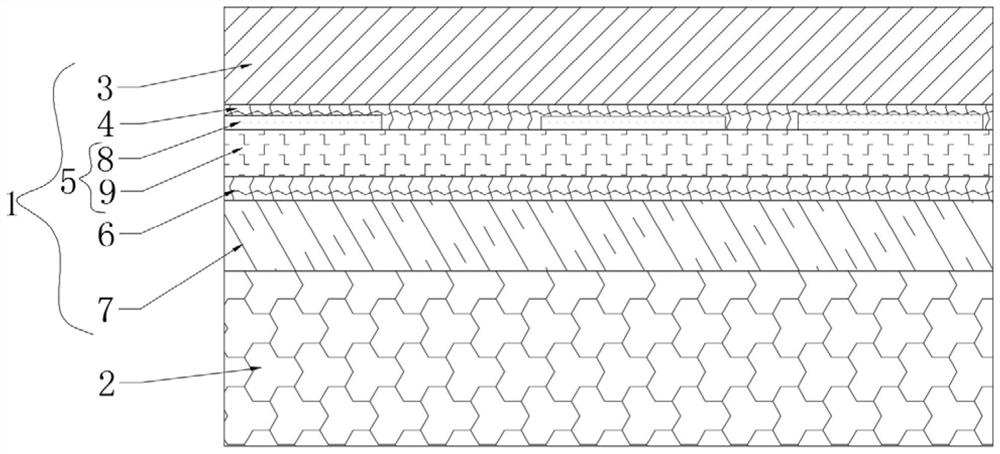

[0033] This embodiment provides an integrated surface light-emitting structure, such as Figure 1~2 As shown, it includes a surface film 1 and a plastic base 2, and the surface film 1 and the plastic base 2 are solidified into one. Specifically, the surface film 1 includes an IMD film 3 , a first adhesive layer 4 , a light emitting layer 5 , a second adhesive layer 6 and a receiving layer 7 from top to bottom. Wherein, the IMD film 3 can be selected from PC film, PET film or PMMA film, and its surface hardness can reach 2-3H. The first adhesive layer 4 and the second adhesive layer 6 can be made of transparent water-based polyurethane adhesive or polyacrylic adhesive. The luminescent layer 5 is made of a luminescent material 8 and a polymer 9, the luminescent material 8 adopts a responsive fluorescent material and / or phosphorescent material, and the polymer 9 adopts polyvinylidene fluoride, polyethylene, polypropylene or polycarbonate. The luminescent material 8 can be a liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com