Early strength concrete with frost resistance and preparation method thereof

A concrete and performance technology, applied in the field of building materials, can solve the problems of the influence of concrete compressive strength and the difficulty of controlling the air content of concrete, etc., and achieve the effect of improving frost resistance and strength performance, and improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

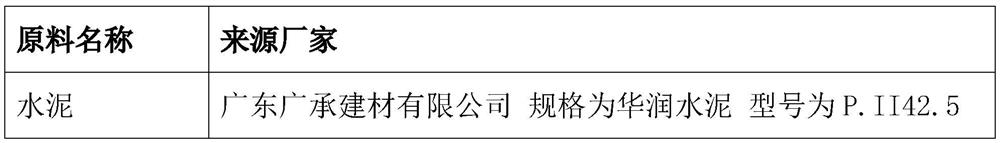

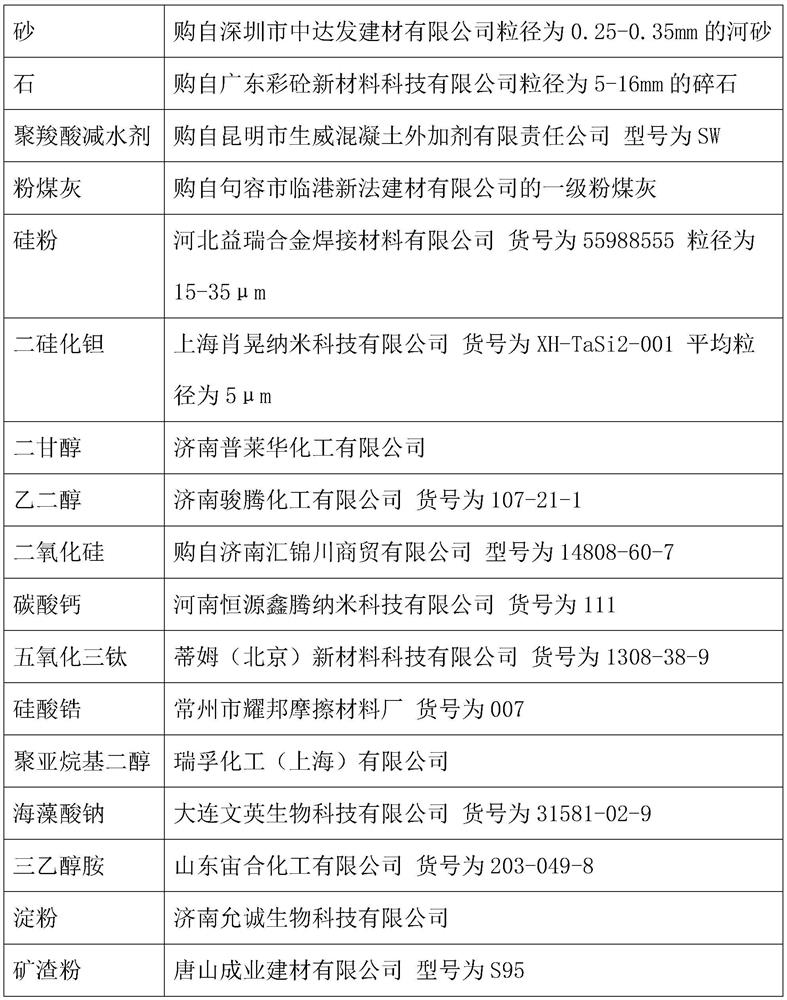

Method used

Image

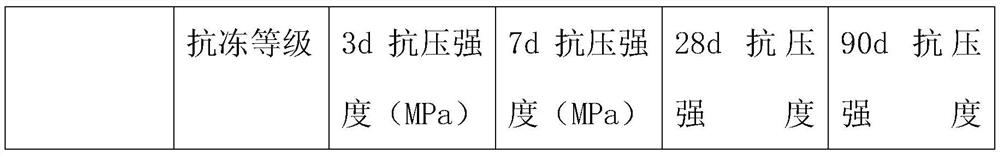

Examples

Embodiment 1

[0053] This embodiment discloses a kind of early-strength concrete with antifreeze performance, comprising the following components:

[0054] Cement 200kg; water 160kg; sand 765kg; stone 1050kg; polycarboxylate superplasticizer 5kg; fly ash 80kg; silicon powder 72kg; tantalum disilicide 7kg;

[0055] In this embodiment, the additive is silicon dioxide.

[0056] This embodiment also discloses a preparation method of early-strength concrete with frost resistance, comprising the following steps:

[0057] Step (1), add 200kg of cement, 765kg of sand, 1050kg of stone, 80kg of fly ash, 72kg of silicon powder, 7kg of tantalum disilicide, 5kg of diethylene glycol and 80kg of water into the mixer machine, and stir evenly to form a premix.

[0058] In step (2), continue to add 5 kg of polycarboxylate superplasticizer and 2 kg of silicon dioxide to the premix while stirring, and stir evenly to form an intermediate mixture.

[0059] In step (3), add the remaining 80 kg of water to the i...

Embodiment 2

[0062] The difference with embodiment 1 is:

[0063] Early-strength concrete with frost resistance consists of components of the following qualities:

[0064]Cement 207kg; water 150kg; sand 770kg; stone 1055kg; polycarboxylate superplasticizer 3kg; fly ash 85kg; silicon powder 69kg; tantalum disilicide 3kg;

Embodiment 3

[0066] The difference with embodiment 1 is:

[0067] Early-strength concrete with frost resistance consists of components of the following qualities:

[0068] Cement 215kg; water 155kg; sand 760kg; stone 1060kg; polycarboxylate superplasticizer 4kg; fly ash 75kg; silicon powder 65kg; tantalum disilicide 5kg;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com