Multi-sensor-based mobile integrated wine picking device

A mobile, multi-sensing technology, applied in the field of brewing, can solve problems such as no consideration of temperature, bubbles are easily affected by surrounding environmental factors, complex and difficult modeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings, but this does not limit the protection scope of the present application.

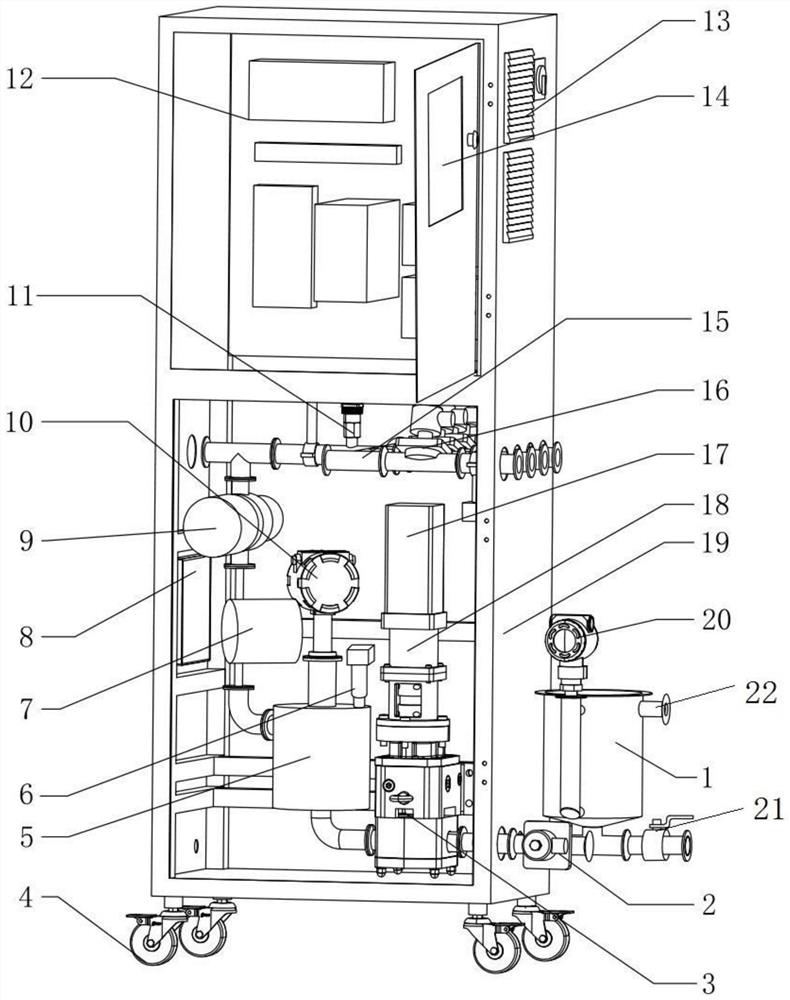

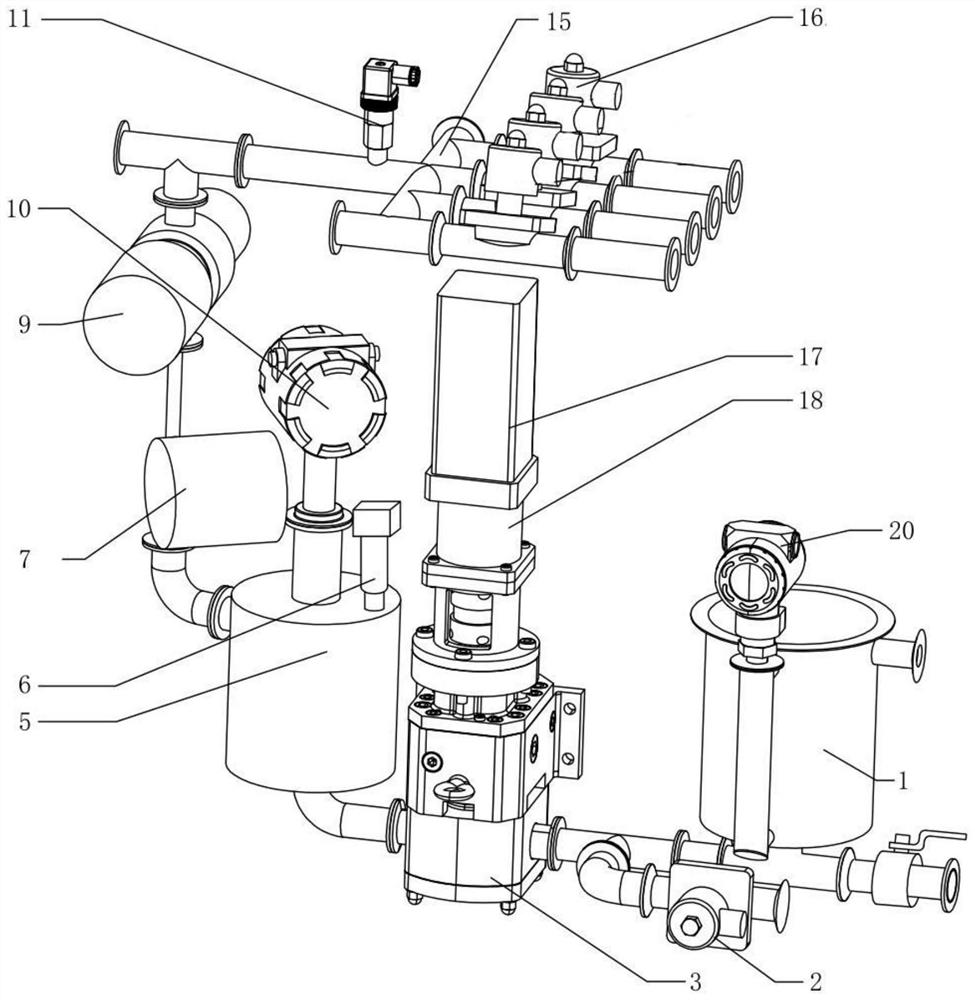

[0021] Such as figure 1 As shown, a kind of mobile integrated wine-picking device (abbreviation device) based on multi-sensing of the present invention comprises a wine collection barrel 1, a delivery pump 3, a collection pot 5, a temperature sensor 6, a flow meter 7, a refractometer 9, Tuning fork density sensor 10, drive motor 17, mobile cabinet 19 and liquid level gauge 20;

[0022] The mobile cabinet 19 is divided into upper and lower layers, the upper layer is used to install the electrical control module 12 and the host computer 14, and the lower layer is used to install the rest of the components; The outer side of the body 19; the entrance of the upper part of the wine collection barrel 1 leads into the raw wine cooled by the external co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com