Process and system for combining waste electricity hydrogen production with circulating fluidized bed boiler combustion

A circulating fluidized bed and boiler combustion technology, applied in the direction of combustion air/fuel supply, combustion methods, chemical industry, etc., can solve the problems of large thermal inertia, limit the deep peak-shaving performance of circulating fluidized bed boilers, etc., and achieve improved The effect of fluidizing wind speed, solving fluidization safety problems, and improving response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0034] A typical implementation of the present invention provides a process for producing hydrogen from waste electricity combined with combustion in a circulating fluidized bed boiler, including a hydrogen production process from electrolyzed water and a combustion and power generation process in a circulating fluidized bed boiler;

[0035] During deep peak shaving, a part of the flue gas from the combustion power generation process of the circulating fluidized bed boiler is extracted as the circulating flue gas, a part of the circulating flue gas is mixed with air or oxygen to obtain primary air, and the primary air enters the furnace from the lower part of the furnace as fluidized air. Mix another part of the circulating flue gas with oxygen to obtain the secondary air, and send the secondary air into the furnace from the upper part of the furnace; the oxygen content in the primary air is lower than that in the air, and the oxygen content in the secondary air is higher than t...

Embodiment 1

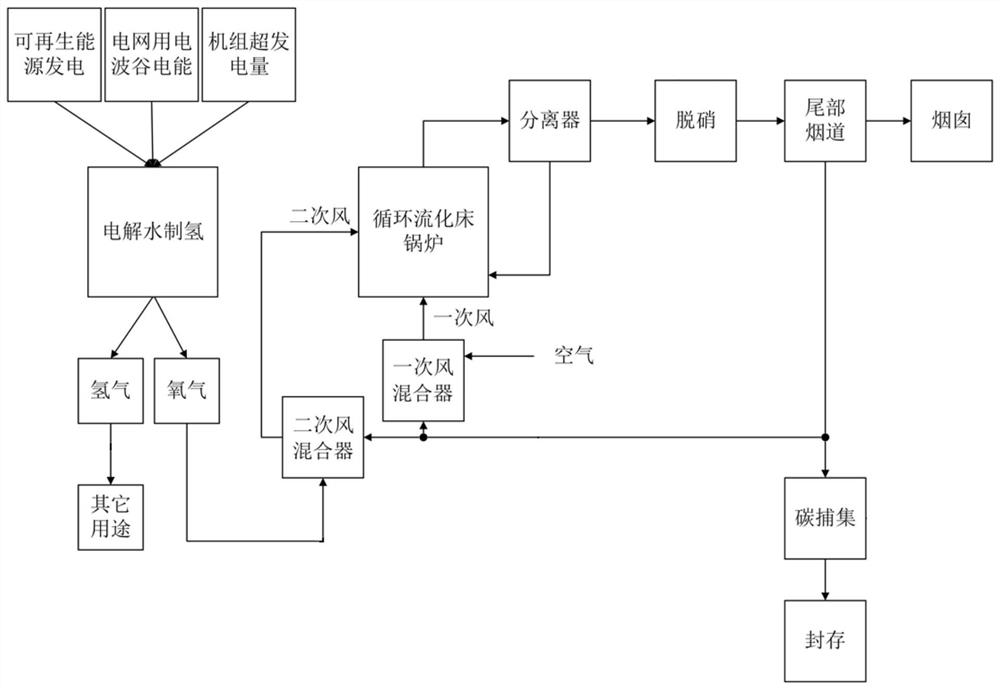

[0061] A process for hydrogen production from waste electricity combined with circulating fluidized bed boiler combustion, such as figure 1 As shown, the part of hydrogen production by electrolysis of water can use the abandoned electricity generated by solar photovoltaic or photothermal power generation during the day, and can use the cheap electricity during the power valley of the power grid at night to electrolyze water to produce hydrogen and oxygen. At the same time, during deep peak regulation Use the off-grid power generated by the unit itself to electrolyze water to produce hydrogen and oxygen. The hydrogen produced is used in hydrogen fuel cells, hydrogen-cooled generators, and other chemical industries. The oxygen obtained by the electrolysis of water can be mixed with the recirculated flue gas through the secondary air mixer and enter the circulating fluidized bed furnace as the secondary air, forming an oxidizing atmosphere in the upper part of the furnace, thereb...

Embodiment 2

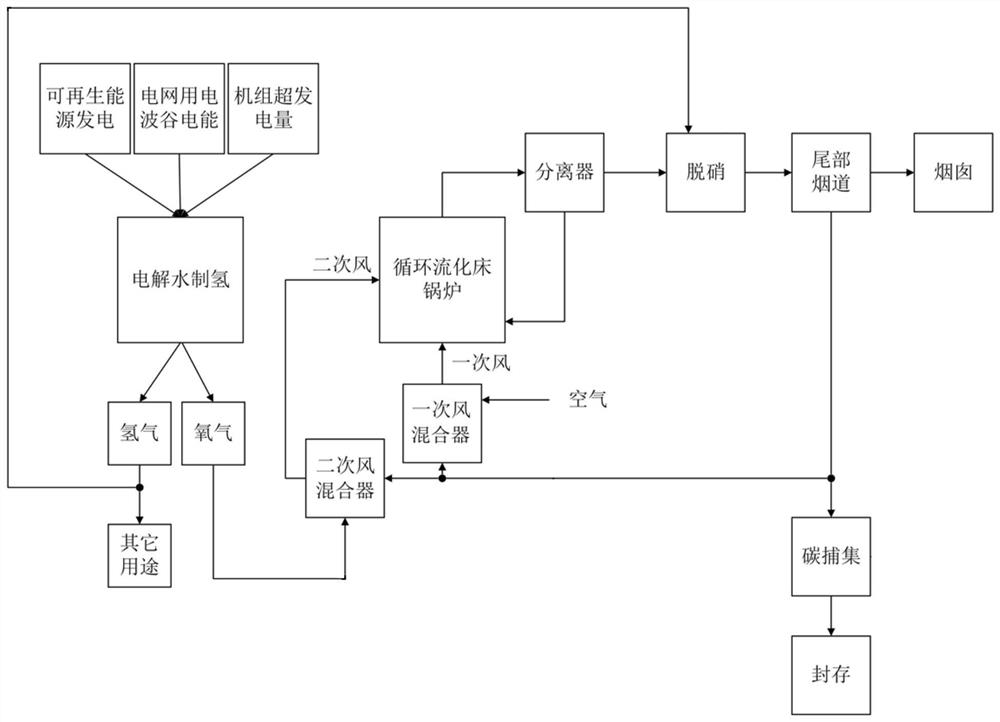

[0064] A process for hydrogen production from waste electricity combined with circulating fluidized bed boiler combustion, such as figure 2 As shown, the part of hydrogen production by electrolysis of water can use the abandoned electricity generated by solar photovoltaic or photothermal power generation during the day, and can use the cheap electricity during the power valley of the power grid at night to electrolyze water to produce hydrogen and oxygen. At the same time, during deep peak regulation Use the off-grid power generated by the unit itself to electrolyze water to produce hydrogen and oxygen. Part of the produced hydrogen is used for hydrogen fuel cells, hydrogen-cooled generators, and other chemical industries, and the other part is used for flue gas denitrification. The oxygen obtained by the electrolysis of water can be mixed with the recirculated flue gas through the secondary air mixer and enter the circulating fluidized bed furnace as the secondary air, formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com