Diluting, sampling and testing equipment for combustion chamber tail gas smoke

A test equipment and combustion chamber technology, applied in the preparation of test samples, sampling devices, measuring devices, etc., can solve the problems of loss of primary condensed particles, fast emission of combustion smoke, unfavorable particle collection, etc., to achieve air tightness The effect of good design, reduced particle loss, and improved portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

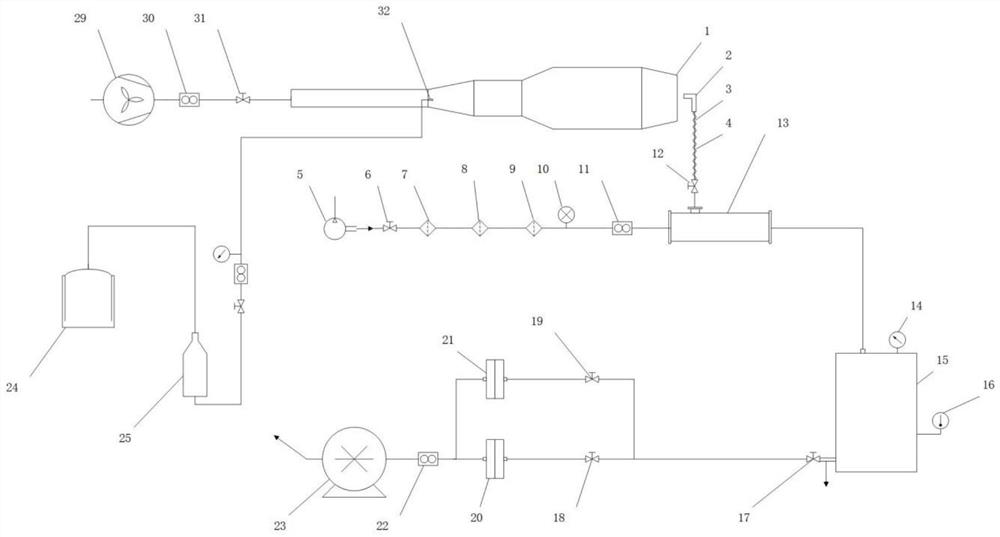

[0020] like figure 1 As shown, the combustion chamber exhaust smoke dilution sampling test equipment is composed of a dilution sampling system and a burner. The dilution sampling system is divided into five parts: a flue gas collection system, a clean air generation system, a Venturi mixer, a dwelling chamber, and a sampling system. The sub-systems, except the clean air generating system and staying outdoors, the rest of the systems are placed on a movable platform with wheels at the bottom, which is convenient to move to different sampling locations, such as indoor test bench component test site, outdoor airborne site, etc.

[0021]The flue gas collection system consists of a sampling probe 2, a sampling pipe 3, and a heating belt 4. The sampling tube 3 is made of stainless steel with a smooth inner wall, and the heating belt is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com