First-order electro-optical effect silicon modulator and preparation process thereof

A technology of electro-optic effect and preparation process, applied in the direction of light guide, optics, instrument, etc., can solve the problems of low modulation efficiency, large device size, weak plasma dispersion effect, etc., and achieve the goal of improving modulation efficiency, reducing insertion loss, and optimizing electro-optic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

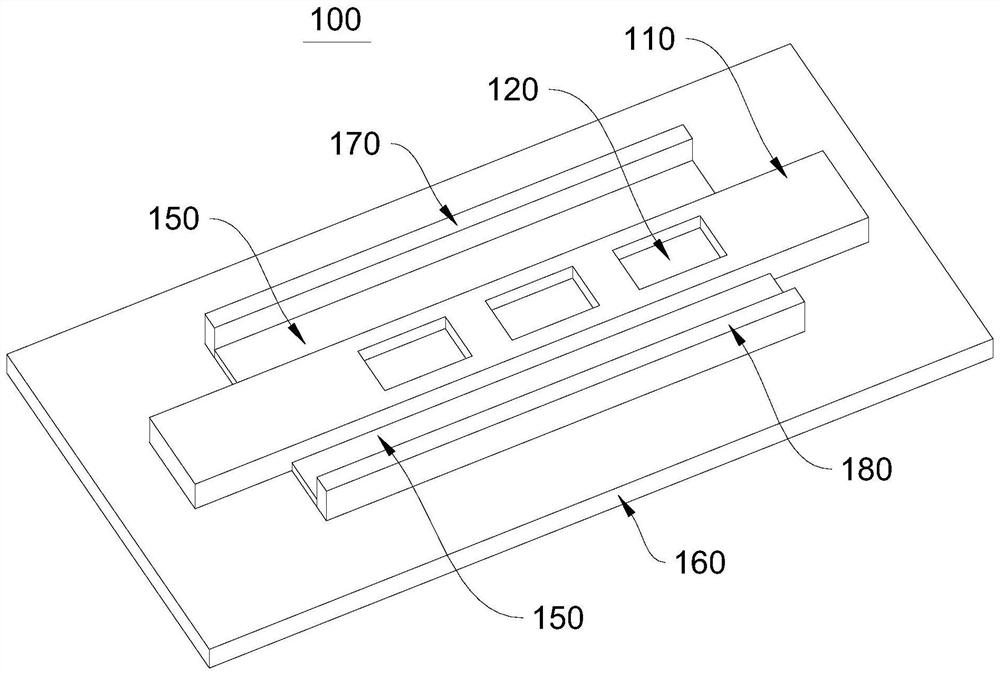

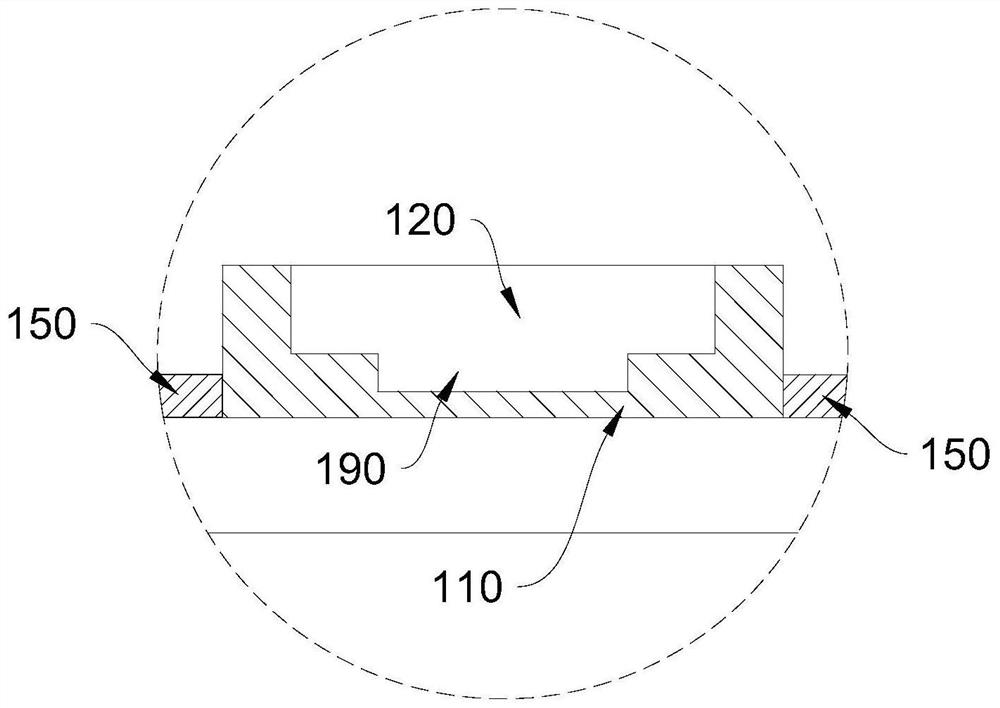

[0046] Please refer to figure 1 , figure 2 and image 3 , this embodiment provides a manufacturing process of a first-order electro-optic effect silicon modulator 100, which includes:

[0047] An amorphous silicon growth window 120 is formed by etching the silicon waveguide region 110, and the amorphous silicon growth window 120 is formed by etching the upper surface of the silicon waveguide region 110; an auxiliary window 190 is also provided at the bottom of the amorphous silicon growth window 120, and the auxiliary window 190 is formed by Etching the bottom of the amorphous silicon growth window 120;

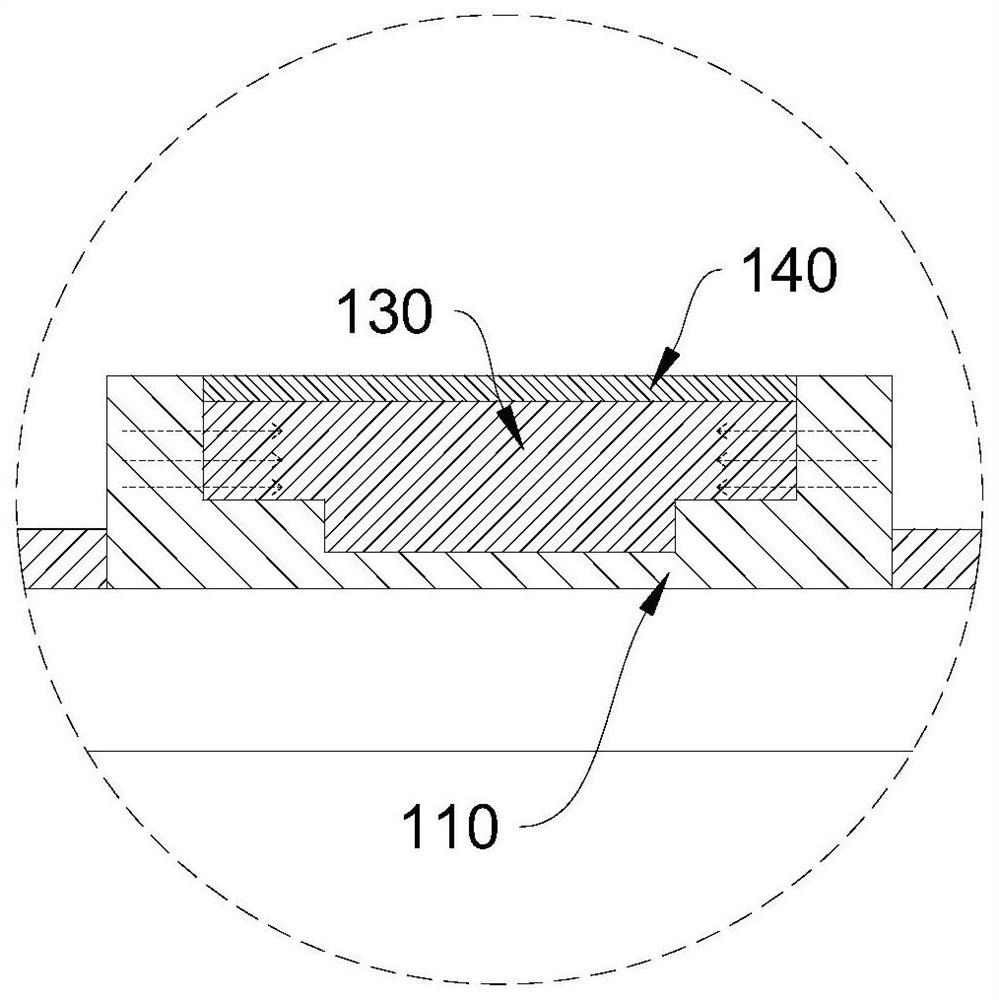

[0048] Depositing amorphous silicon 130 in the amorphous silicon growth window 120, and covering the surface of the deposited amorphous silicon 130 with a silicon dioxide layer 140;

[0049] Irradiating the amorphous silicon growth window 120 with light having a wavelength of 488 nm converts at least a portion of the amorphous silicon 130 in the amorphous silicon growth w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com