Preparation method of corrosion-resistant conductive grounding carbon steel in-situ coating

A carbon steel, in-situ technology, applied in the direction of contact manufacturing, connecting contact materials, etc., can solve the problems of uneven coating, poor adhesion of external coating, and continuous consumption of resources by cathodic protection technology. Reduce corrosion rate, avoid long-term consumption and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

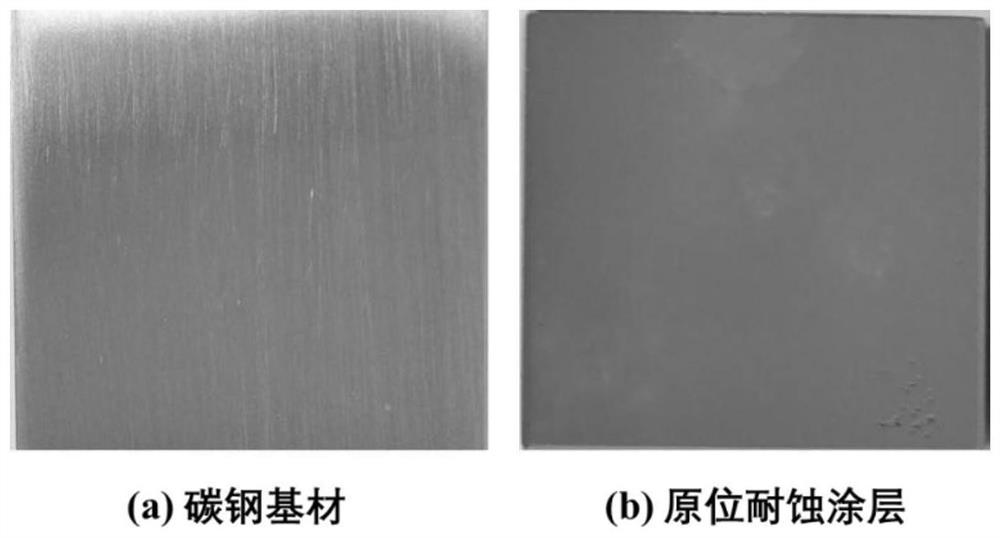

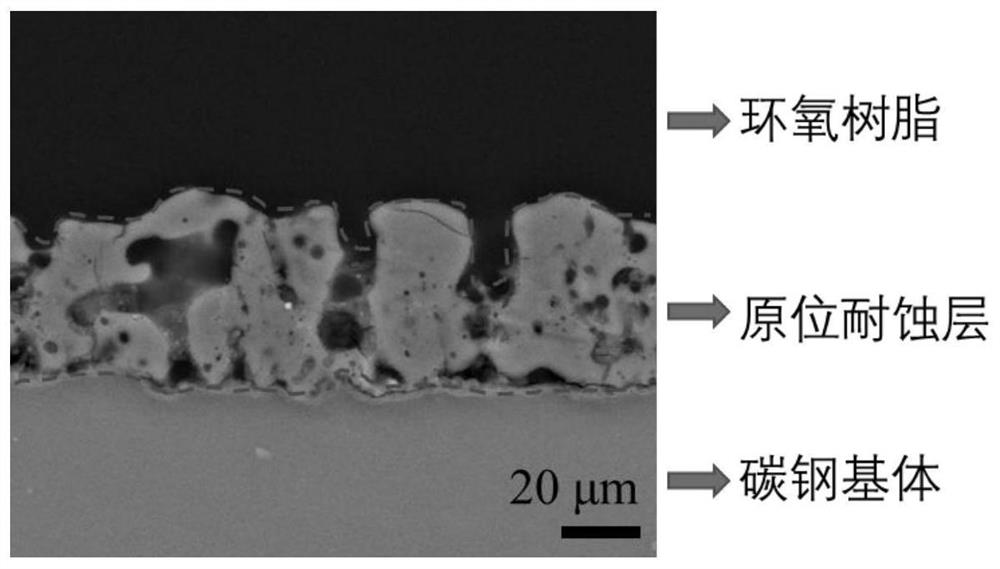

[0025] A method for preparing an in-situ coating of corrosion-resistant grounded carbon steel, comprising the steps of:

[0026] (1) Surface pretreatment of carbon steel: Wipe the carbon steel with ethanol solution and sand it for 10 minutes under 100# silicon carbide sandpaper;

[0027] (2) The treated carbon steel is used as the anode, the graphite plate is used as the cathode, and the ratio of the surface area of the carbon steel to the surface area of the graphite plate is 1:20. Placed in the in-situ electrolyte, the temperature of the electrolyte is controlled at 40°C, the stirring speed is 300r / min, the setting parameters of the DC power supply are current 0.5A, frequency 50Hz, the power is turned on for in-situ treatment, and the treatment stops after 30 minutes

[0028] Electrolytic treatment for a certain period of time, the components and contents of the in-situ treatment solution are: 5g / L sodium metaaluminate, 5g / L sodium hexametaphosphate, 3g / L sodium carbonat...

Embodiment 2

[0032] The method of Example 1 was repeated according to the content of each component specified in Table 1 below, and the test results are listed in Table 1.

Embodiment 3

[0034] The method of Example 1 was repeated according to the content of each component specified in Table 1 below, and the test results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com