Application of sodium azide in degradation of organic matters and method for treating organic wastewater by ozone

A technology of organic wastewater and sodium azide, which is applied in special compound water treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of economic and convenience limitations, metal ion pollution, etc., and achieve improved reliability Biochemical properties, the effect of simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

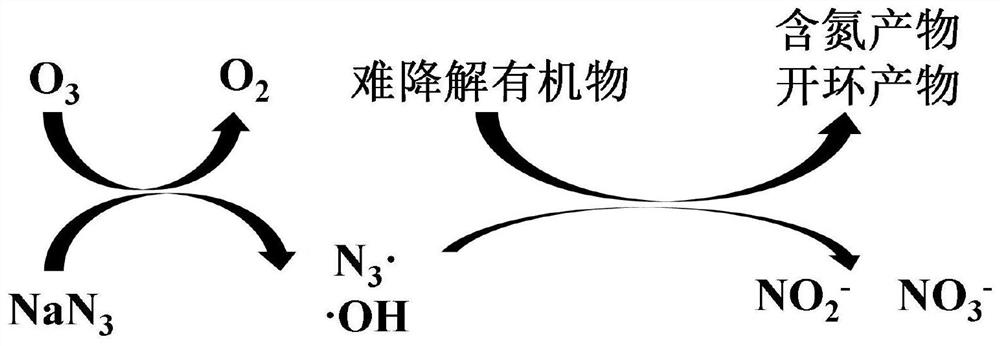

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The organic pollutant in organic wastewater is atrazine. The initial concentration of atrazine is 1mg / L, the reaction temperature is 10°C, the reaction pH value is 3, NaN 3 The dosage of ozone is 0.3mg / L, the dosage of ozone is 3mg / L, NaN 3 The dosing method is one-time dosing, and the reaction time is 30 minutes. After testing, the removal rate of atrazine was 100%.

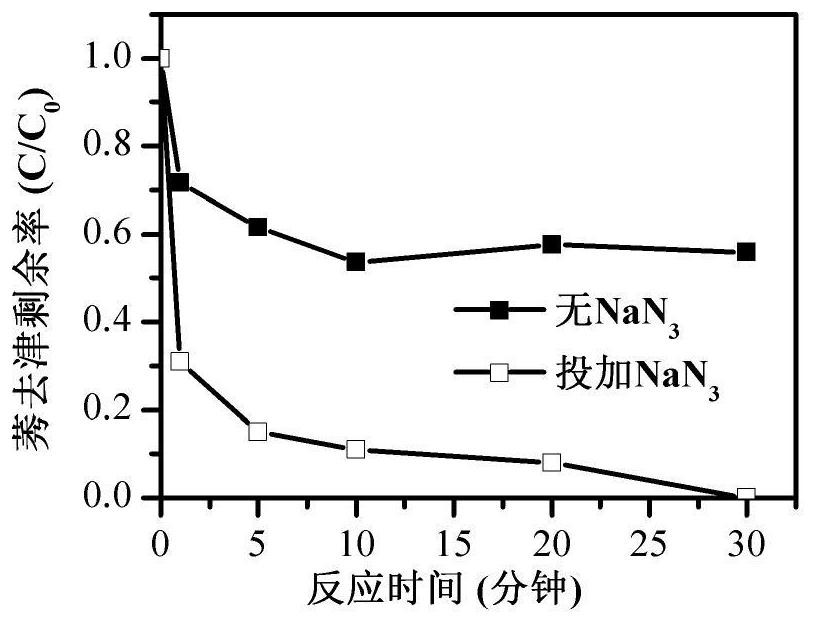

[0030] The degradation effect of organic matter atrazine in embodiment 1 sees as figure 2 As shown, among them, the dotted line indicates that there is no NaN 3 Degradation curve of atrazine, □ dotted line indicates NaN 3 Degradation curve of atrazine in the presence. From figure 2 It can be seen that when atrazine was treated for 10 minutes, no NaN was added 3 The remaining rate of atrazine in the solution was about 50% and NaN was added 3 The remaining rate of atrazine in the solution is about 10%. As reaction time increases without NaN addition 3 The remaining rate of atrazine in the soluti...

Embodiment 2

[0032] The organic pollutant in organic wastewater is atrazine. The initial concentration of atrazine is 10mg / L, the reaction temperature is 20°C, the reaction pH value is 3, NaN 3 The dosage is 5mg / L, the dosage of ozone is 30mg / L, NaN 3 The dosing method is continuous dosing for 10 minutes, and the reaction time is 60 minutes. After testing, the removal rate of atrazine was 95%.

Embodiment 3

[0034] The organic pollutant in organic wastewater is atrazine. The initial concentration of atrazine is 100mg / L, the reaction temperature is 15°C, the reaction pH value is 7, NaN 3 The dosage of ozone is 100mg / L, the dosage of ozone is 200mg / L, NaN 3 The dosing method is continuous dosing for 60 minutes, and the reaction time is 60 minutes. After testing, the removal rate of atrazine was 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com