Method for deeply removing COD (Chemical Oxygen Demand) in wastewater

A waste water and depth technology, applied in chemical instruments and methods, water/sewage treatment, natural water treatment, etc., can solve the problems of increased power consumption of water production, increased cost of chemicals, high cost of use, etc., to reduce operating costs and reduce chroma , the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1, a centralized sewage treatment plant in a pharmaceutical park mainly collects and treats biopharmaceutical wastewater. The upstream biopharmaceutical types include chlortetracycline, chlortetracycline hydrochloride, oxytetracycline, coenzyme Q10, penicillin, pesticides, veterinary drugs, enzyme preparations, etc. . Design water volume 12000m 3 / d.

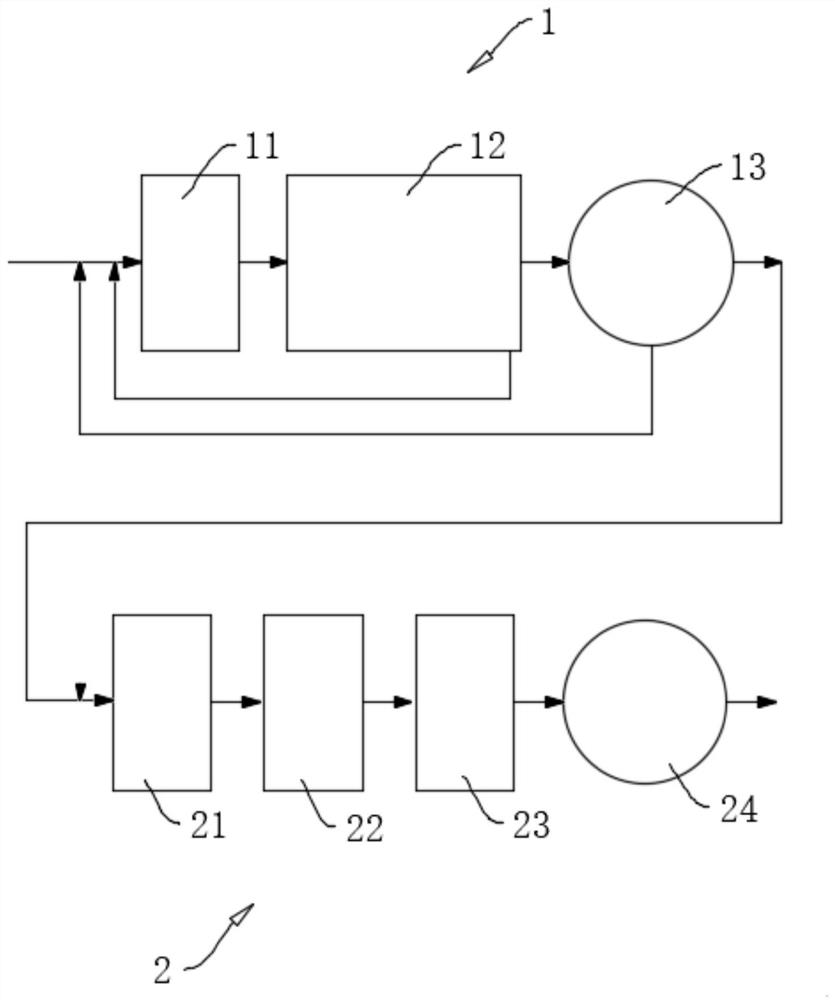

[0045] In this embodiment, a method for deep removal of COD in wastewater includes a biochemical treatment system 1 and a chemical dosing coupled sedimentation system 2 . The sludge concentration of the biochemical treatment system 1 is controlled at 10-13g / L. The biochemical treatment system 1 includes a hydrolysis tank 11, an aerobic tank 12 and a secondary sedimentation tank 13, and the hydrolysis tank 11 and the aerobic tank 12 are circulating water tanks. The sludge age in the aerobic tank 12 was maintained at 60 days, the sludge age in the aerobic tank 12 was maintained at 120 days, and the sludge load in ...

Embodiment 2

[0050] A pharmaceutical factory produces waste water. The products include amoxicillin, cephalosporin antibiotics, tylosin, acetylspiramycin, abamectin, 7ACA and veterinary antibiotics (tilmicosin, tilmicosin phosphate, etc.). Design water volume 20000m 3 / d.

[0051] The sewage treatment device of this embodiment includes an A / O treatment system and an oxidation coupled advanced treatment system. The sludge concentration of the biochemical treatment system 1 is controlled at 8-10 g / L. The biochemical treatment system 1 includes a hydrolysis tank 11, an aerobic tank 12 and a secondary sedimentation tank 13. The hydrolysis tank 11 and the aerobic tank 12 are circulating water tanks. The sludge age in the aerobic tank 12 was maintained at 120 days, and the sludge load in the aerobic tank 12 was 0.05gCOD / (gMLSS·d). Sewage is added to the hydrolysis tank 11, the mixed solution after hydrolysis in the hydrolysis tank 11 enters the aerobic tank 12, and the mixed solution at one en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com