Composite oxide supported double transition metal catalysts for fixed-bed catalytic hydrogenation of hydroquinone to 1,4-cyclohexanediol

A composite oxide, transition metal technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst carrier, etc., can solve the problem of high catalyst price, long reaction time and complex separation process and other problems, to achieve the effect of improving catalytic efficiency, increasing production capacity, and increasing conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

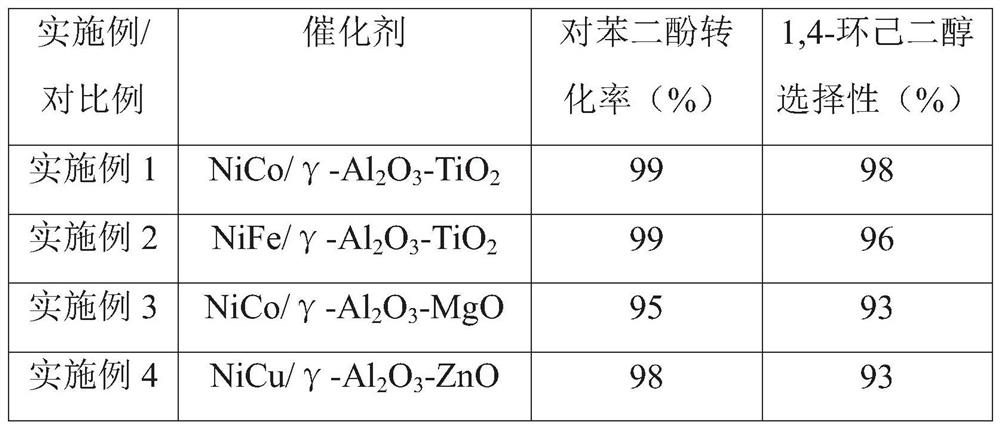

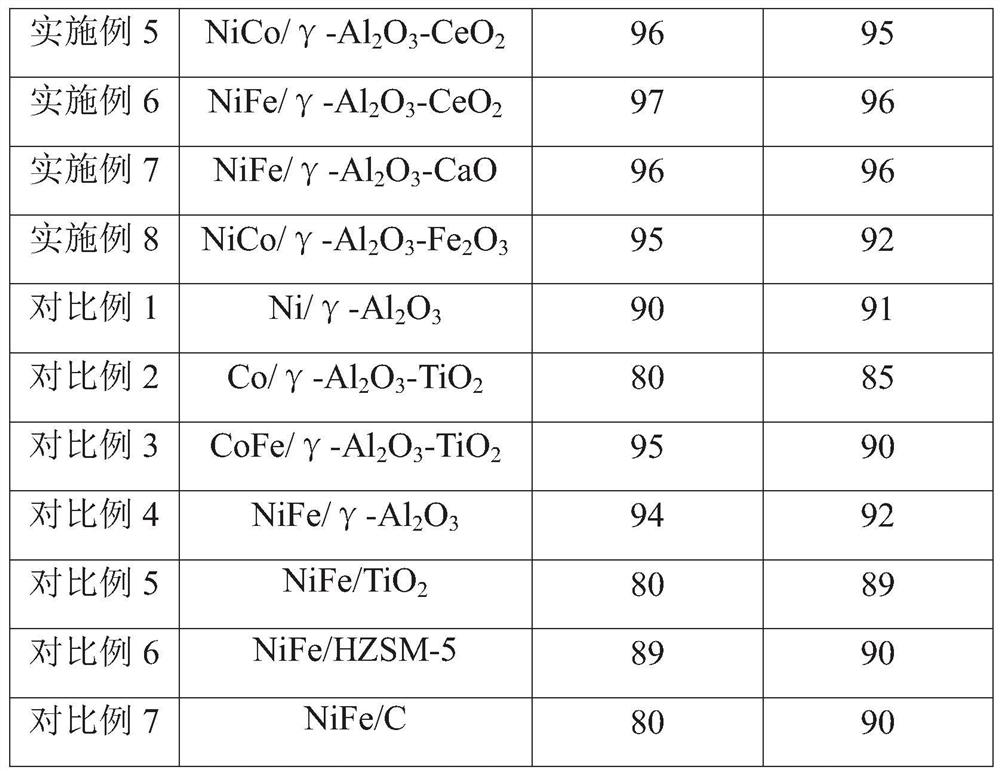

Examples

Embodiment 1

[0023] Weigh 4g Ni (NO 3 ) 2 ·6H 2 O and 1g Co(NO 3 ) 2 ·6H 2 O was dissolved in 20 g of water. Then immersed in mechanically ground 90 g of γ-Al 2 O 3 and 10gTiO 2 in the mixture. Evaporate the solvent in a water bath at 60°C, dry in an oven at 120°C for 24h, calcinate in air at 500°C for 4h, in the reactor GHSV=6000h -1 In the flow rate, 0.1MPa hydrogen was maintained at 550 °C for 3h to obtain the activated γ-Al 2 O 3 and TiO 2 Supported NiCo-based catalyst, denoted as NiCo / γ-Al 2 O 3 -TiO 2 .

[0024] At 150°C, 2.5MPa, the H 2 Filled in 90g ethanol solution dissolved in 10g hydroquinone, H 2 The molar ratio of hydroquinone / hydroquinone is 30:1, and the hydroquinone solution LHSV=4h -1 , the catalyst volume is 0.5 mL. Off-line analysis of liquid products, DB-1701 capillary column, FID detector to analyze the content of hydroquinone and 1,4-cyclohexanediol.

Embodiment 2

[0026] Weigh 3g Ni (NO 3 ) 2 ·6H 2 O and 2g Fe(NO 3 ) 2 ·6H 2 O was dissolved in 20 g of water. Then immersed in mechanically ground 10 g of γ-Al 2 O 3 and 90g TiO 2 in the mixture. Evaporate the solvent in a water bath at 80°C, dry in an oven at 150°C for 24h, calcinate in air at 500°C for 2h, in the reactor GHSV=5000h -1 In the flow rate, 0.1MPa hydrogen was maintained at 550 °C for 3h to obtain the activated γ-Al 2 O 3 and TiO 2 Supported NiFe-based catalyst, denoted as NiFe / γ-Al 2 O 3 -TiO 2 .

[0027] At 150°C, 1.5MPa, the H 2 Filled in 90g ethanol solution dissolved in 10g hydroquinone, H 2 The molar ratio of hydroquinone / hydroquinone is 20:1, the hydroquinone solution LHSV=5h -1 , the catalyst volume is 1 mL. Off-line analysis of liquid products, DB-1701 capillary column, FID detector to analyze the content of hydroquinone and 1,4-cyclohexanediol.

Embodiment 3

[0029] Weigh 2g Ni (NO 3 ) 2 ·6H 2 O and 3g Co(NO 3 ) 2 ·6H 2 O was dissolved in 20 g of water. Then immersed in 50 g of mechanically ground γ-Al 2 O 3 and 50 g of MgO. Evaporate the solvent in a water bath at 60°C, dry in an oven at 120°C for 24h, calcinate in argon at 400°C for 4h, in the reactor GHSV=6000h -1In the flow rate, 0.1MPa hydrogen was maintained at 550 °C for 3h to obtain the activated γ-Al 2 O 3 and MgO-supported NiCo-based catalysts, denoted as NiCo / γ-Al 2 O 3 -MgO.

[0030] At 150°C, 2.5MPa, the H 2 Filled in 90g ethanol solution dissolved in 10g hydroquinone, H 2 The molar ratio of / hydroquinone is 30:1, the hydroquinone solution LHSV=6h -1 , the catalyst volume is 0.5 mL. Off-line analysis of liquid products, DB-1701 capillary column, FID detector to analyze the content of hydroquinone and 1,4-cyclohexanediol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com