Antibacterial low-odor master batch as well as preparation method and application thereof

A low-odor, masterbatch technology, applied in the field of polymer materials, can solve the problems of inability to achieve antibacterial effect, peculiar smell, unsuitable for automotive interior materials, etc., achieve synergistic antibacterial material odor, reduce material odor, and be suitable for large-scale production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

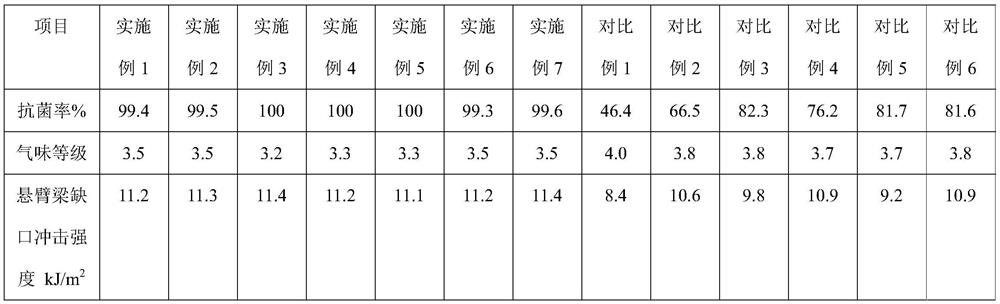

Examples

Embodiment 1~5 and comparative example 1~4

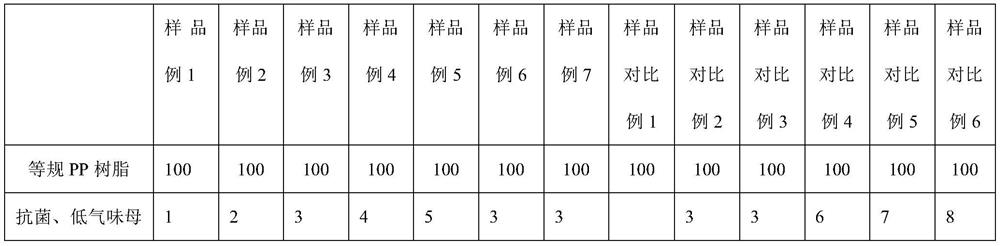

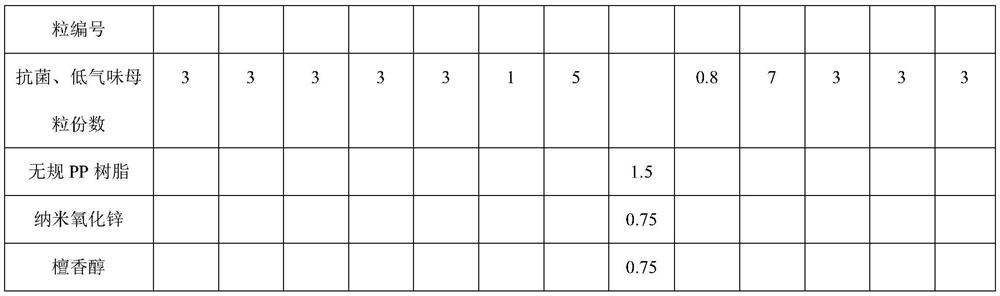

[0043] An antibacterial, low-odor masterbatch, including the components calculated in parts by weight as shown in Table 1 below.

[0044] The antibacterial of each embodiment of table 1 and comparative example, the formula of low odor masterbatch

[0045] project Example 1 Example 2 Example 3 Example 4 Example 5 Comparative example 1 Comparative example 2 Comparative example 3 Master batch number 1 2 3 4 5 6 7 8 Random PP resin 100 100 100 100 100 100 100 Isotactic PP resin 100 Nano Zinc Oxide 20 80 50 40 60 15 85 50 Sandalol 80 20 50 60 40 85 15 50

[0046] The preparation method of above-mentioned antibacterial, low odor masterbatch, comprises the steps:

[0047] For the examples and comparative examples 1-2, add random PP resin, nano-zinc oxide and santalyl alcohol into the high mixer in proportion, mix for 1-3 minutes at 200-300 rpm, and then add the mixed raw materials in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com