Steel cord and manufacturing method thereof

A steel cord and steel wire technology, applied in the field of steel cord, can solve the problems of insufficient rubber penetration, affecting tire fatigue performance, cord warping, etc., and achieve good rubber penetration performance, increase tire life, and improve fatigue performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

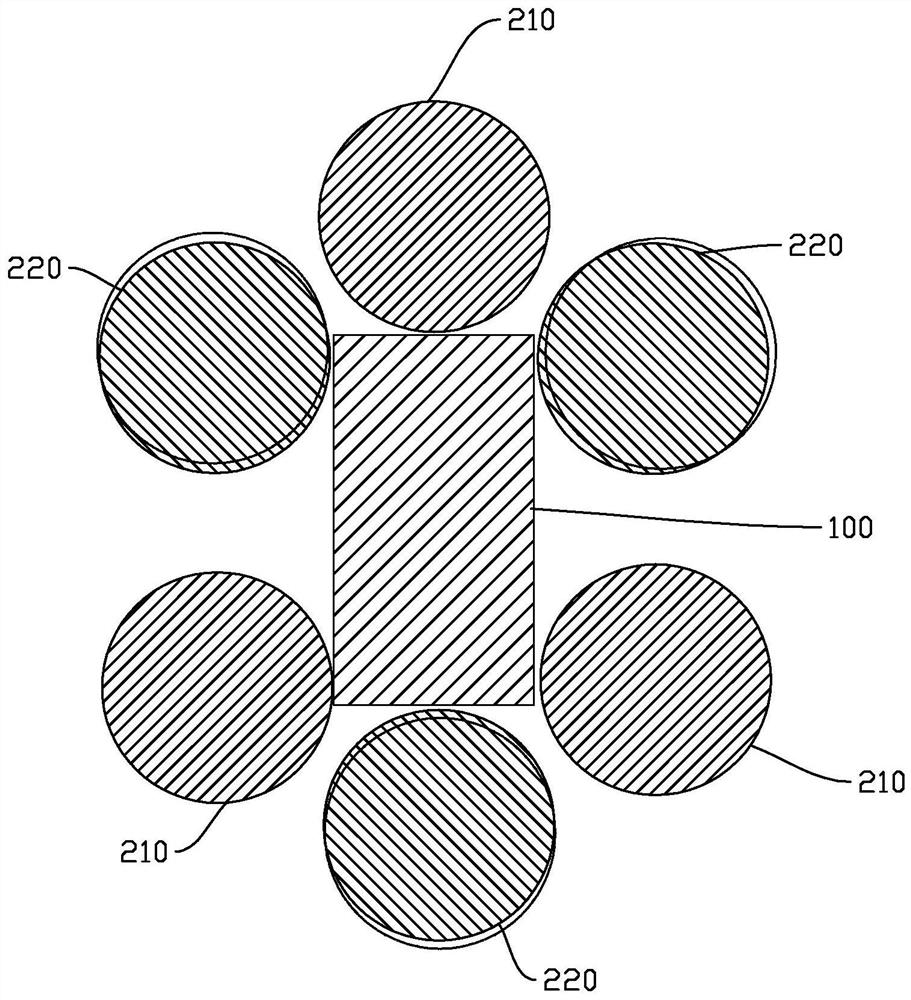

[0033] The cross section of the central steel wire is rectangular, with a central steel wire and 6 sheath steel wires, the width of the central steel wire is 0.38mm, the thickness of the central steel wire is 0.28mm, and the three sheath steel wires are pre-deformed, pre-formed by a polygonal pre-deformer or by The gear meshes and deforms, and the remaining three sheath wires do not have deformation. The diameters of the three sheath wires with pre-deformation are 0.28 mm, and the diameters of the three sheath wires without deformation are 0.30 mm.

Embodiment 2

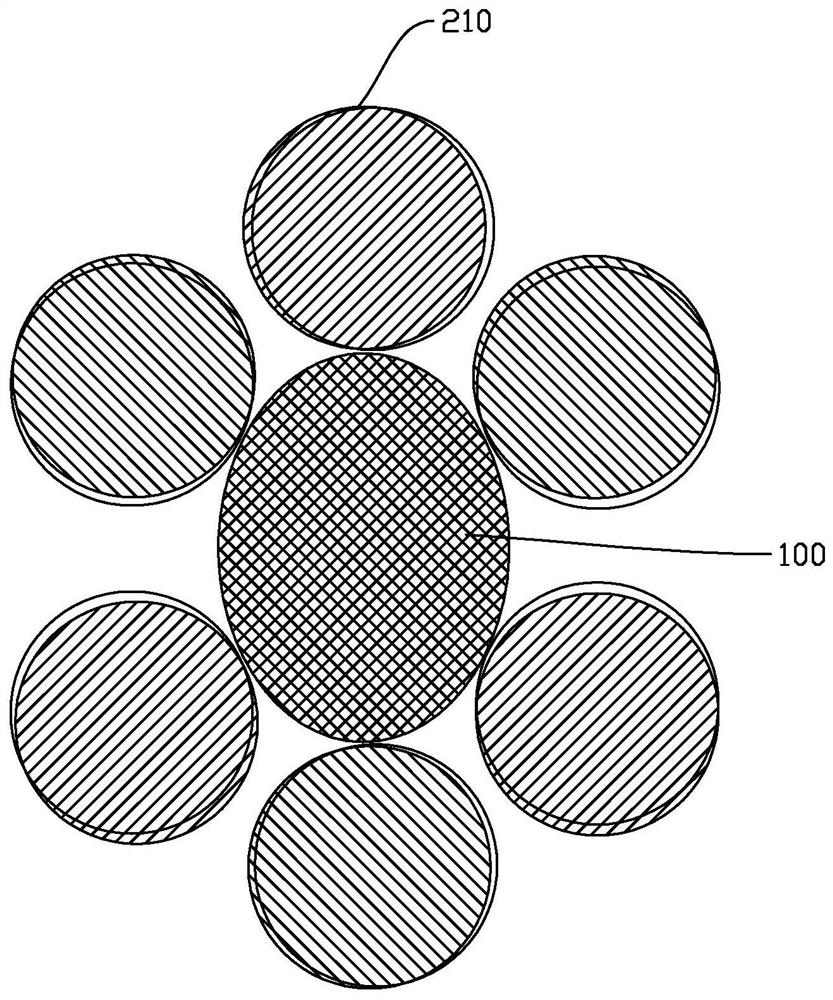

[0035] The cross-section of the central steel wire is elliptical, with one central steel wire and six sheath steel wires. The major axis a value of the central steel wire is 0.42mm, the short axis b value of the central steel wire is 0.31mm, and the diameter of the six sheath steel wires is 0.32mm. Pre-deform via the polygonal pre-deformer.

Embodiment 3

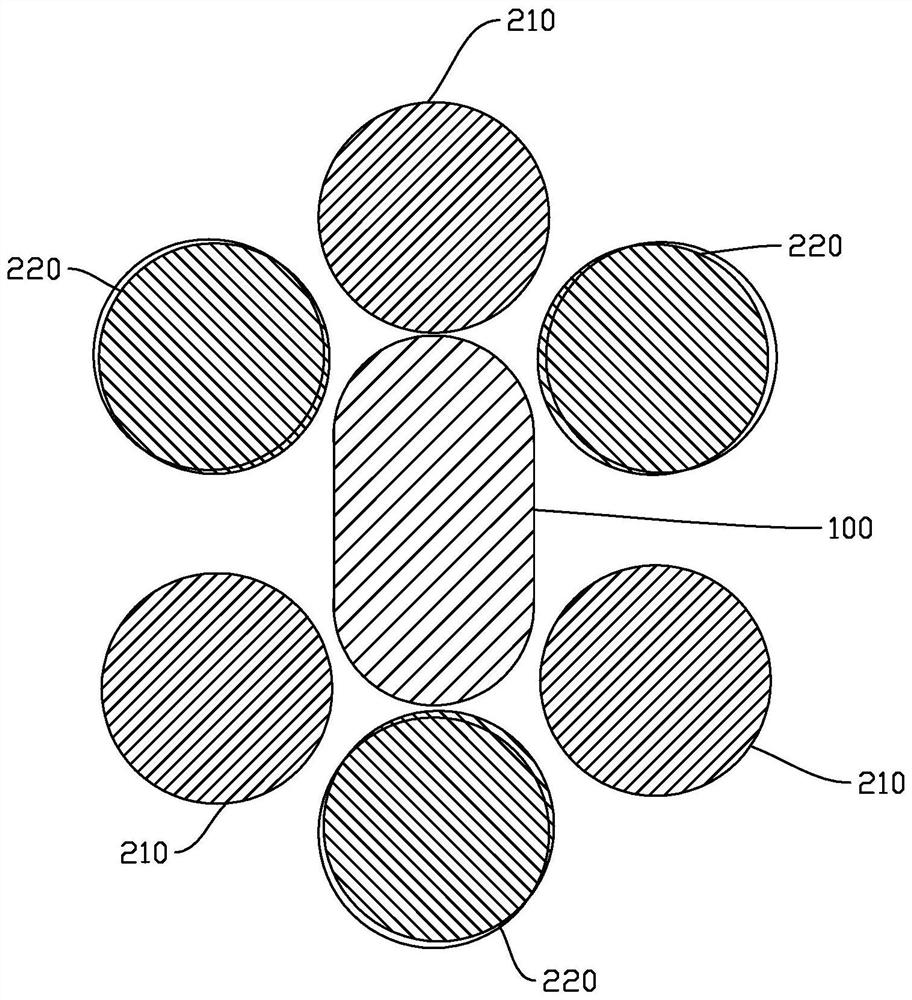

[0037] The cross-section of the central steel wire is waist-circular, with a central steel wire and 6 sheath steel wires. The width of the central steel wire is 0.40mm, and the thickness of the central steel wire is 0.30mm. Or through gear meshing deformation, the remaining three sheath wires do not have deformation, the diameter of the three sheath wires with pre-deformation is 0.30mm, the wave height of the deformed steel wires is between 0.35-0.38mm, and the three sheath wires without deformation The diameter is 0.32mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long axis | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com