Diffusion welding method for tungsten target material and copper back plate

A technology of diffusion welding and copper backplane, applied in the field of target manufacturing, can solve the problem of insufficient bonding ability between tungsten target and copper backplane, and achieve the effect of solving the insufficient bonding ability and improving the bonding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

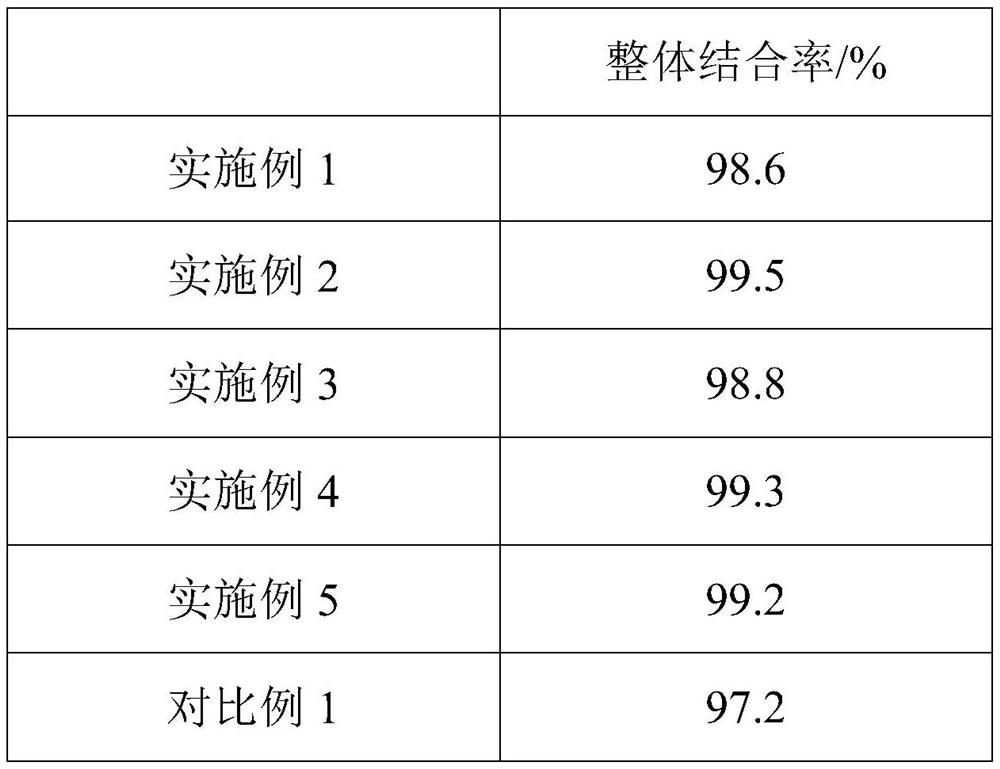

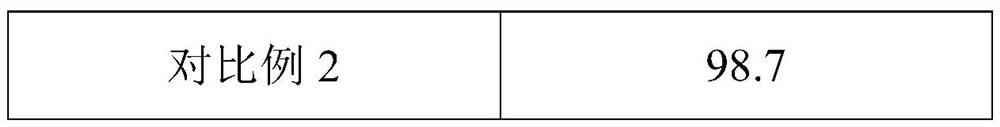

Examples

Embodiment 1

[0047] This embodiment provides a method for diffusion welding of a tungsten target and a copper backplane. The diffusion welding method includes the following steps:

[0048] The welding surface of the tungsten target is finely ground. After the fine grinding, the roughness Ra of the welding surface is ≤ 3 μm. After IPA ultrasonic cleaning, PVD titanium coating is performed. The thickness of the titanium film is 3 μm, and the non-welding surface is polished. Carry out IPA ultrasonic cleaning after described polishing treatment;

[0049] Machining the copper backplane to the assembly size, performing IPA ultrasonic cleaning on the welding surface of the copper backplane after IPA ultrasonic cleaning, the thickness of the titanium film is 3 μm, and performing IPA ultrasonic cleaning after the PVD coating;

[0050]Machining the middle layer to the assembly size, the surface roughness of the middle layer is Ra≤1.6 μm, and performing IPA ultrasonic cleaning after the machining;

...

Embodiment 2

[0055] This embodiment provides a method for diffusion welding of a tungsten target and a copper backplane. The diffusion welding method includes the following steps:

[0056] The welding surface of the tungsten target is finely ground. After the fine grinding, the roughness Ra of the welding surface is ≤ 3 μm. After IPA ultrasonic cleaning, a PVD titanium coating is performed. The thickness of the titanium film is 6 μm, and the non-welding surface is polished. Carry out IPA ultrasonic cleaning after described polishing treatment;

[0057] Machining the copper backplane to the assembly size, performing IPA ultrasonic cleaning on the welding surface of the copper backplane with PVD titanium film, the thickness of the titanium film is 6 μm, and performing IPA ultrasonic cleaning after the PVD coating;

[0058] Machining the middle layer to the assembly size, the surface roughness of the middle layer is Ra≤1.6 μm, and performing IPA ultrasonic cleaning after the machining;

[00...

Embodiment 3

[0063] This embodiment provides a method for diffusion welding of a tungsten target and a copper backplane. The diffusion welding method includes the following steps:

[0064] The welding surface of the tungsten target is finely ground. After the fine grinding, the roughness of the welding surface is Ra≤3μm. After IPA ultrasonic cleaning, PVD titanium coating is performed. The thickness of the titanium film is 3.5μm, and the non-welding surface is polished. , carry out IPA ultrasonic cleaning after described polishing treatment;

[0065] Machining the copper backplane to the assembly size, performing IPA ultrasonic cleaning on the welding surface of the copper backplane with PVD titanium film, the thickness of the titanium film is 3.5 μm, and performing IPA ultrasonic cleaning after the PVD coating;

[0066] Machining the middle layer to the assembly size, the surface roughness of the middle layer is Ra≤1.6 μm, and performing IPA ultrasonic cleaning after the machining;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com