Method for preparing iron phosphate by recycling mother liquor

A technology of iron phosphate and mother liquor, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of comprehensive utilization of resources, high cost of wastewater treatment, unfavorable energy saving and cost reduction, etc., and is beneficial to comprehensive resources Utilization, good appearance, and the effect of reducing the cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

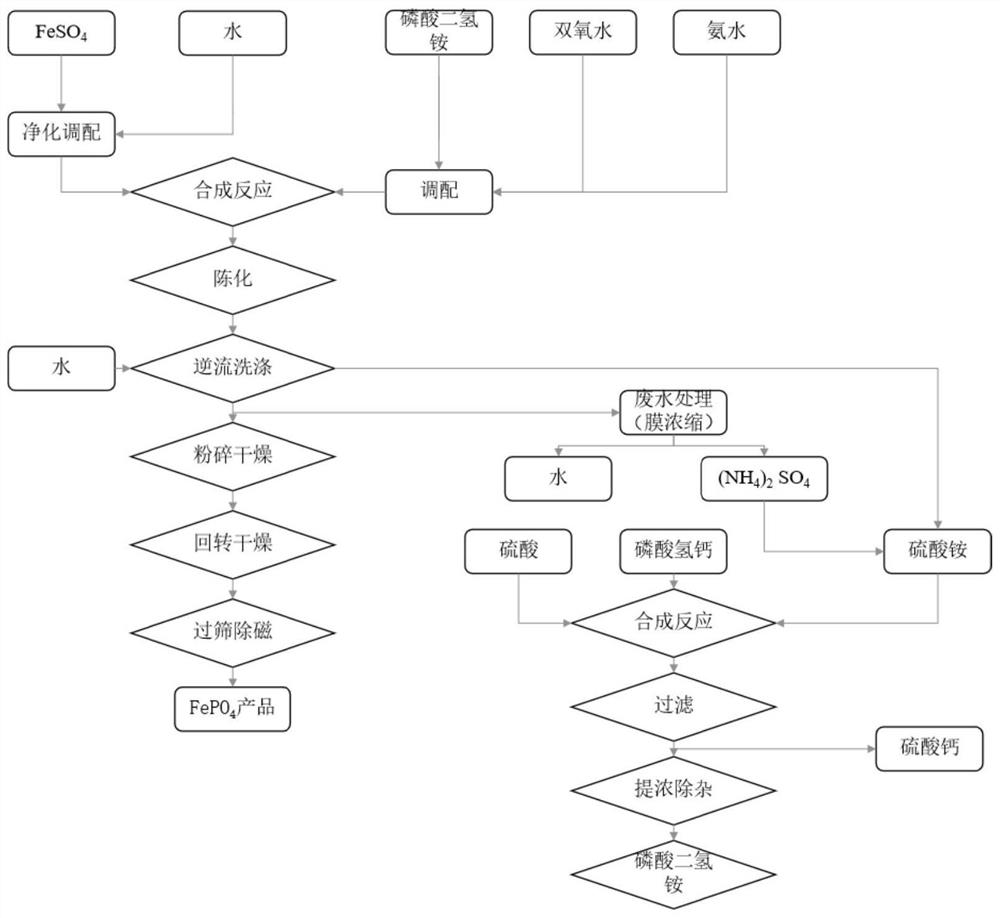

[0032] Such as figure 1 Shown, a kind of mother liquor reuses the method for preparing ferric phosphate, and this method may further comprise the steps:

[0033] 1. Mix calcium hydrogen phosphate, sulfuric acid, and ammonium sulfate mother liquor, stir at 45°C for 60 minutes, and filter to obtain ammonium dihydrogen phosphate solution; the molar ratio of calcium hydrogen phosphate, sulfuric acid, and ammonium sulfate added is 2: 1.05: 1.

[0034] 2. Add hydrogen peroxide to the ammonium dihydrogen phosphate solution, the mol ratio of the consumption of hydrogen peroxide to ferrous sulfate in ferrous sulfate is 0.3:1, mix to obtain filtrate B;

[0035] 3. The filtrate B is mixed with ammonia water to obtain a solution C of pH=2.0, and the solution C is added to the reactor together with the purified ferrous sulfate solution (80g / L) to synthesize and prepare ferric phosphate, according to the method of ammonium dihydrogen phosphate and The molar ratio of ferrous sulfate is 1:1...

Embodiment 2

[0041] Such as figure 1 Shown, a kind of mother liquor reuses the method for preparing ferric phosphate, and this method may further comprise the steps:

[0042] 1. Mix calcium hydrogen phosphate, sulfuric acid, and ammonium sulfate mother liquor, stir at 98°C for 30 minutes, and filter to obtain ammonium dihydrogen phosphate solution; the molar ratio of calcium hydrogen phosphate, sulfuric acid, and ammonium sulfate added is 2.05: 1:1.

[0043] 2. Add hydrogen peroxide in the ammonium dihydrogen phosphate solution, the mol ratio of the consumption of hydrogen peroxide and the ferrous iron in ferrous sulfate is 0.5: 1, mix to obtain filtrate B;

[0044] 3. The filtrate B is mixed with ammonia water to obtain a solution C of pH=7.0, and the solution C is added to the reaction kettle together with the purified ferrous sulfate solution (120g / L), and ferric phosphate is synthesized according to ammonium dihydrogen phosphate and ammonium dihydrogen phosphate. The molar ratio of f...

Embodiment 3

[0050] Such as figure 1 Shown, a kind of mother liquor reuses the method for preparing ferric phosphate, and this method may further comprise the steps:

[0051] 1. Mix calcium hydrogen phosphate, sulfuric acid, and ammonium sulfate mother liquor, stir at 65°C for 45 minutes, and filter to obtain ammonium dihydrogen phosphate solution; the molar ratio of calcium hydrogen phosphate, sulfuric acid, and ammonium sulfate added is 2: 1:1.

[0052] 2. Add hydrogen peroxide in the ammonium dihydrogen phosphate solution, the mol ratio of the consumption of hydrogen peroxide and the ferrous iron in ferrous sulfate is 0.4: 1, mix to obtain filtrate B;

[0053]3. The filtrate B is mixed with ammonia water to obtain a solution C of pH=5.0, and the solution C is added to the reaction kettle together with the purified ferrous sulfate solution (100g / L), and ferric phosphate is synthesized according to ammonium dihydrogen phosphate and ammonium dihydrogen phosphate The molar ratio of ferrou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com