Material for cold-mixing and cold-paving overlay technology and preparation method of material

A cold laying and overlay technology, which is applied in construction, roads, road repairs, etc., can solve problems such as unsatisfactory application effects, and achieve the effects of low driving noise, noise reduction, and damage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of cold-mixed cold-paved overlay technology, comprising the steps of:

[0020] Preparation of cationic one-component waterborne epoxy asphalt mixture: 72 parts of basalt coarse aggregate, 23 parts of basalt fine aggregate, 5 parts of mineral powder, 10 parts of cationic one-component waterborne epoxy asphalt (solid content 60%, The softening point is 87°C, the bonding strength is 0.7MPa, the elongation at break is 85%, the viscosity at 60°C is 25000Pa·S), 3 parts of SBS emulsion, and 2 parts of water are mixed. The results of the aggregate screening experiments are shown in Table 2.

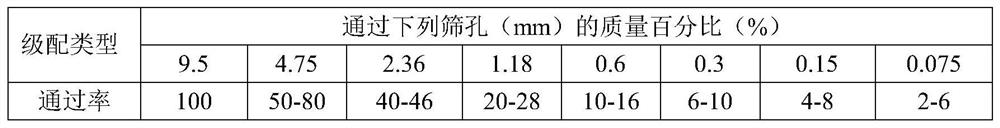

[0021] Table 2 Coarse aggregate and fine aggregate screening test results

[0022]

[0023] Preparation of hydrophobic silicone emulsion: 49 parts of water-based silicone emulsion, 48 parts of water-based silicone acrylic emulsion, 2 parts of triethanolamine, 1 part of water-based dark brown and stirred for 30 minutes.

[0024] The construction method steps of col...

Embodiment 2

[0027] A preparation method of cold-mixed cold-paved overlay technology, comprising the steps of:

[0028] Preparation of cationic one-component waterborne epoxy asphalt mixture: 68 parts of basalt coarse aggregate, 26 parts of basalt fine aggregate, 5 parts of mineral powder, 1 part of cement, 12 parts of cationic one-component waterborne epoxy asphalt (solid content of 61%, softening point of 86°C, bond strength of 0.6MPa, elongation at break of 82%, viscosity of 21000Pa·S at 60°C), 2 parts of SBR emulsion and 1 part of water. The results of the aggregate screening experiments are shown in Table 3.

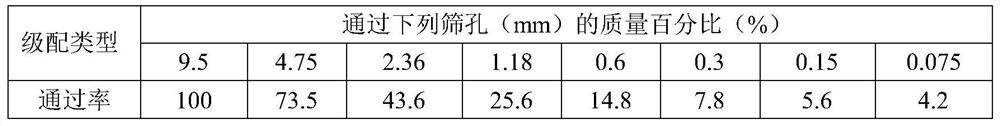

[0029] Table 3 Coarse aggregate and fine aggregate screening test results

[0030]

[0031] Preparation of hydrophobic silicone emulsion: 35 parts of water-based silicone emulsion, 61 parts of water-based silicone acrylic emulsion, 2 parts of tallow-based primary amine, and 2 parts of water-based dark brown emulsion were prepared by stirring for 30 minutes.

[0032] The con...

Embodiment 3

[0035] A preparation method of cold-mixed cold-paved overlay technology, comprising the steps of:

[0036] Preparation of cationic one-component waterborne epoxy asphalt mixture: 72 parts of basalt coarse aggregate, 24 parts of basalt fine aggregate, 4 parts of mineral powder, 14 parts of cationic one-component waterborne epoxy asphalt (solid content 59%, The softening point is 89°C, the bonding strength is 0.68MPa, the elongation at break is 88%, the viscosity at 60°C is 21530Pa·S), 2 parts of SBS emulsion, 1 part of SBR emulsion, and 4 parts of water are mixed. The results of the aggregate screening experiments are shown in Table 4.

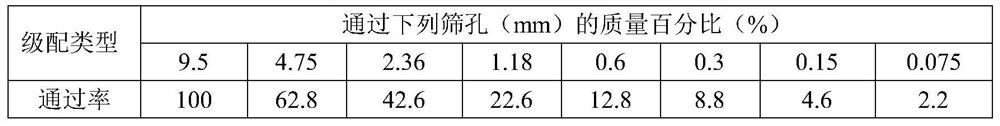

[0037] Table 4 Coarse aggregate and fine aggregate screening test results

[0038]

[0039] Preparation of hydrophobic silicone emulsion: 55 parts of water-based silicone emulsion, 41 parts of water-based silicone acrylic emulsion, 3 parts of laurylamine, and 1 part of water-based dark brown emulsion were prepared by stirring for 30 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com