Preparation method of chemical igniter for testing dust explosion characteristic of energetic material

A technology for dust explosion and ignition tools, applied in ignition devices, explosives, offensive equipment, etc., can solve problems such as large environmental pollution and dust generation, and achieve the effects of low price, strong ignition ability, and avoiding toxicity problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

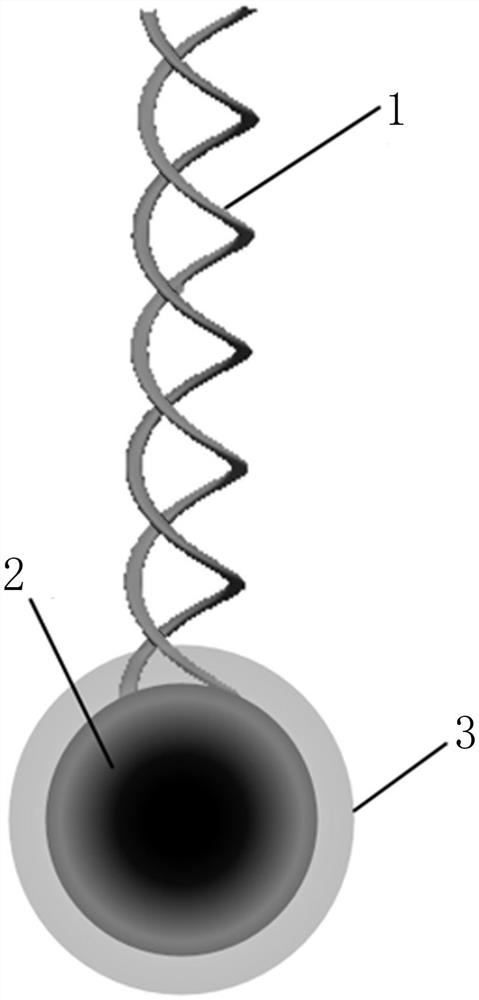

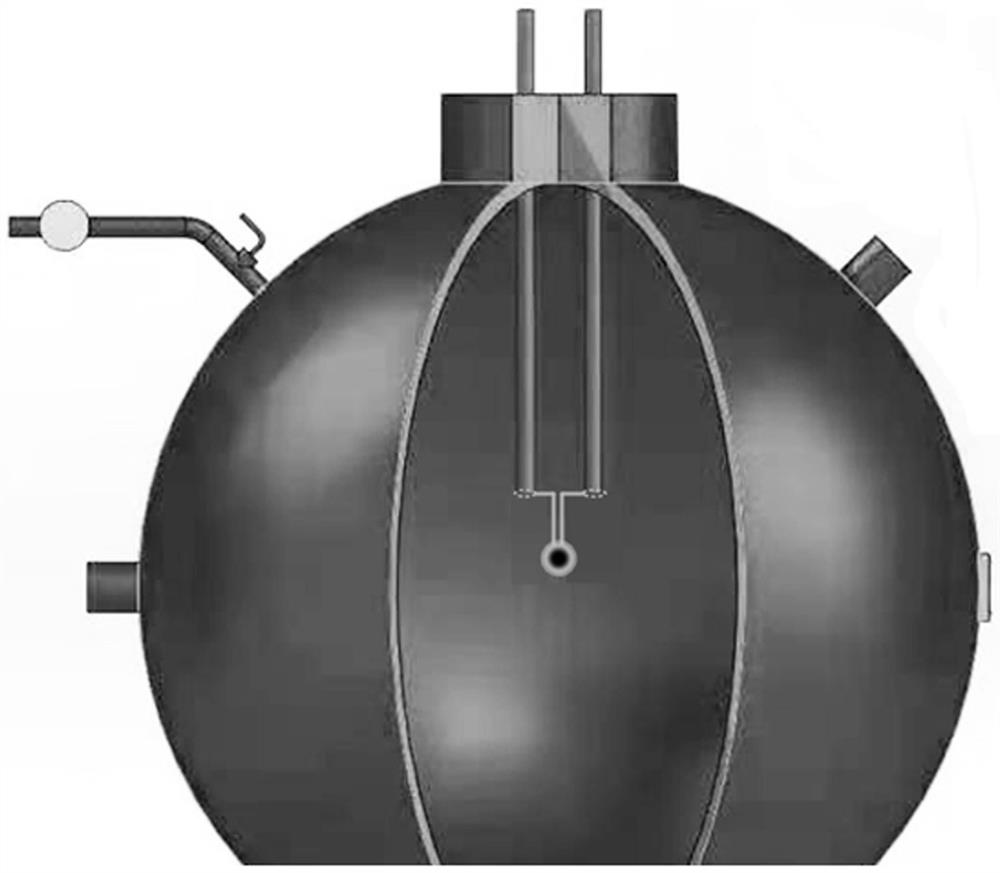

Image

Examples

Embodiment

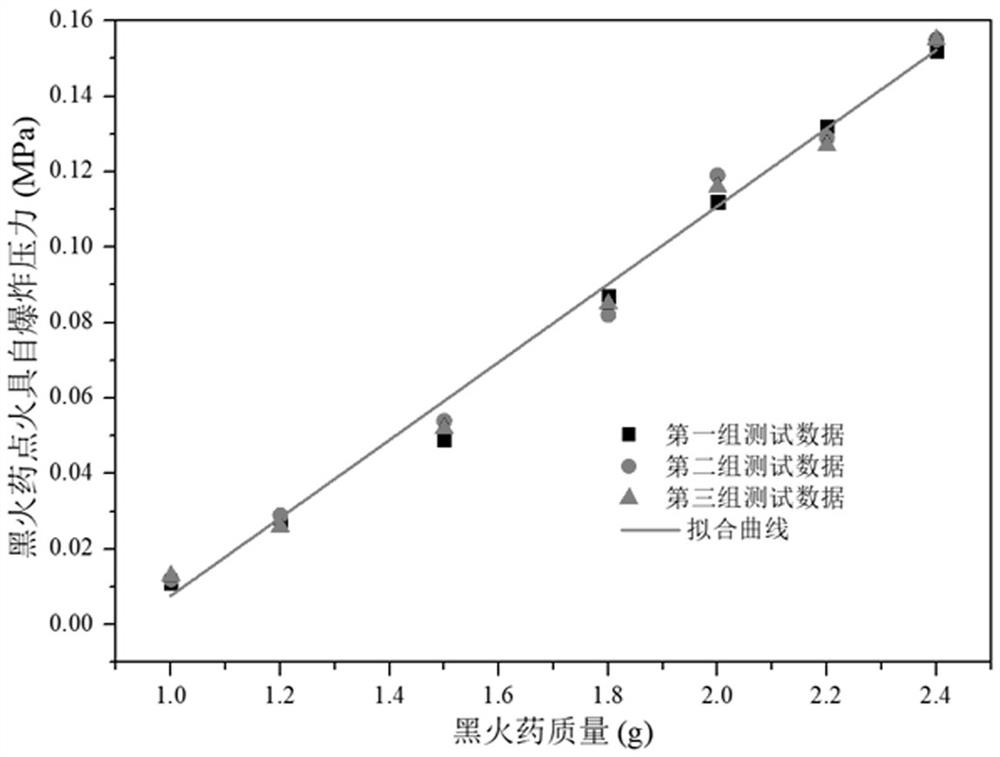

[0022] Performance comparison with traditional igniters suitable for industrial dust in the national standard: Using piezoelectric sensors, the pressure generated by the self-explosion of chemical igniters made of black powder in 20L explosion test balls was tested. Each group of experiments was repeated 3 times, and the self-explosion pressure and the explosion pressure versus time curves of black powder masses of 0g, 1.0g, 1.2g, 1.5g, 1.8g, 2.0g, 2.2g, and 2.4g were obtained.

[0023] from image 3 It can be seen from the fitting line in the figure that the mass of the black powder igniter is basically in a linear relationship with the self-explosion pressure of the black powder. The greater the mass of the igniter, the greater the pressure generated by its self-explosion. from Figure 4 It can be seen from the figure that the time for black powder igniters of different qualities to reach the maximum pressure is basically about 0.25 s. The maximum explosion pressure and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com