Pipeline mounting support with novel structure

A new type of pipeline installation technology, which is applied in the direction of pipeline supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of large interference from the surrounding environment, vibration or jitter displacement, unscientific and reasonable structure, etc., to avoid using Cost expenditure, reduce daily use cost, more scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

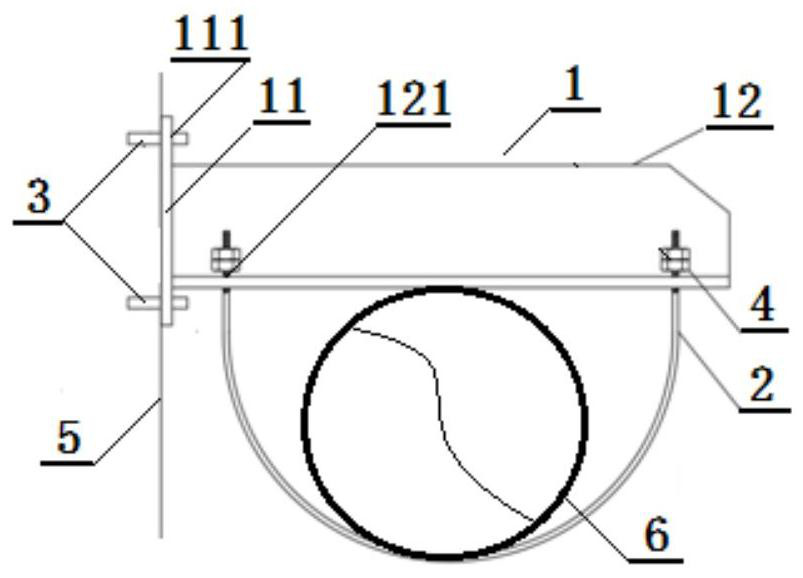

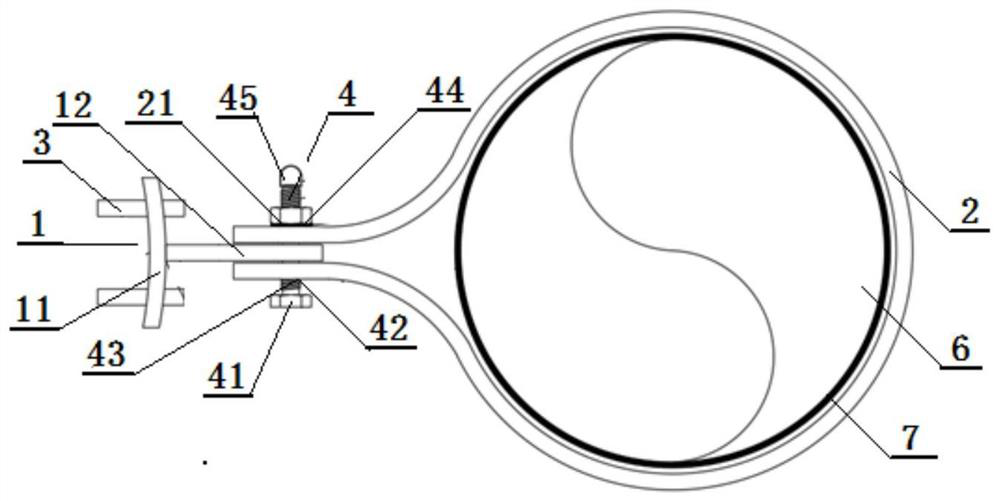

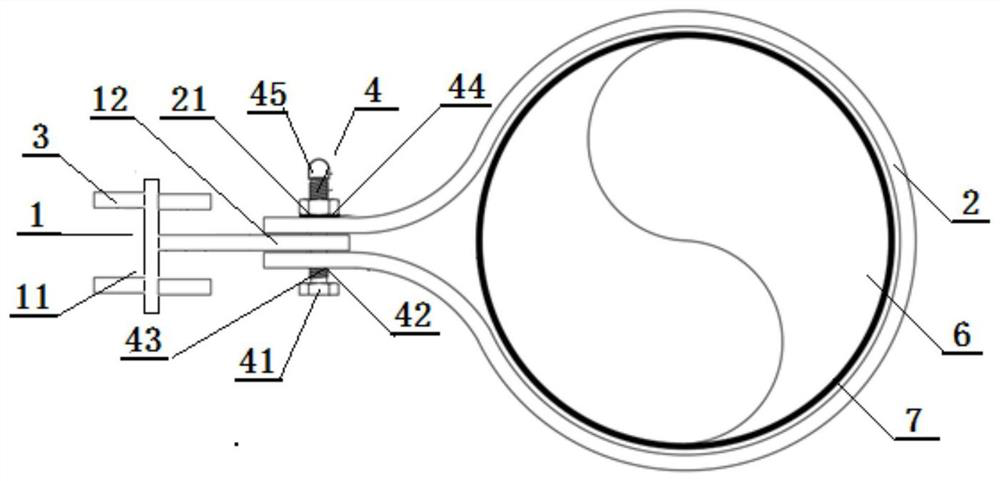

[0024] exist Figure 2 to Figure 8 Among them, the pipe installation bracket with a new structure of the present invention, the main body includes a seat frame 1, a clamp 2, a fastening expansion bolt 3 for fixing the seat frame 1 on the structural column 5, and a fastening limit pipe 6 on the clamp 2 The hoop fastener 4 in the encirclement is characterized in that it also includes a pipeline damping washer 7, wherein:

[0025] The main body of the seat frame 1 is in a short T-shape, including a seat plate 11 made of an arc-shaped steel plate or a flat steel plate conforming to the surface of the structural column 5 and provided with several installation limit holes 111, vertical Solid welded on the seat plate 11, made of a strip steel plate whose length is less than the diameter of the pipe, and provided with several shorter legs 12 with assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com