White peach oolong flavor dry egg cake formula and preparation method thereof

A technology of dried oolong cakes, which is applied in the direction of baking, baked foods with modified ingredients, and tuber baked foods, etc., which can solve the problems of insufficient nutrients, low moisture content, and insignificant efficacy of dry cakes, and achieve the goal of maintaining intestinal Normal function of the intestinal tract, low moisture content, and rich nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

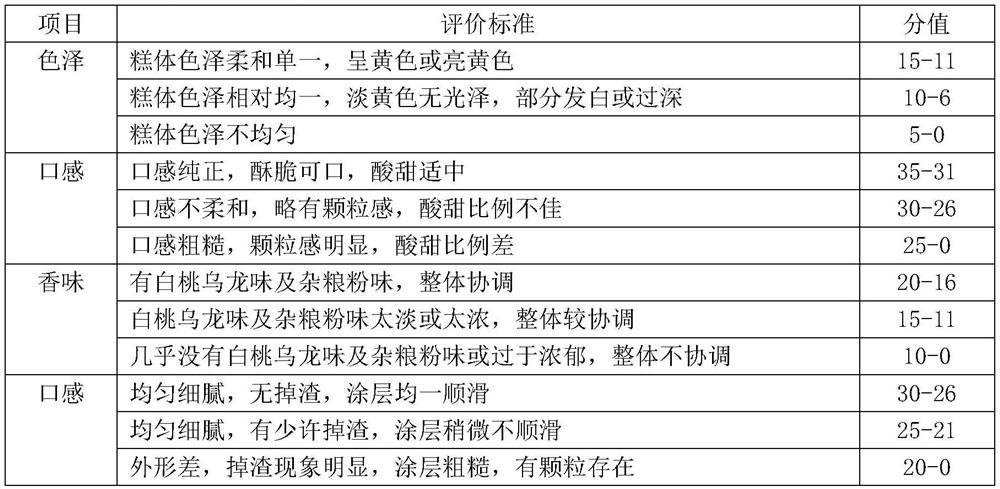

Examples

Embodiment 1

[0027] Recipe: 50g wheat flour, 11g black whole wheat flour, 20g buckwheat flour, 2g konjac powder, 0.2g edible salt, 2.5g white peach oolong tea powder, 1g baking powder, 0.4g citric acid, 16.4g salad oil, 0.4g tartar powder, Egg 210g, milk 55g, fructo-oligosaccharide 80g, galacto-oligosaccharide 20g, allulose 40g, white cocoa butter 40g, soybean lecithin 1g, γ-aminobutyric acid 0.2g.

[0028] The processing technology is as follows:

[0029] Step (1) Preparation of mixed flour, put the weighed wheat flour, buckwheat flour, black whole wheat flour, konjac powder, edible salt, white peach oolong tea powder (accounting for 2 / 3 of the total amount of white peach oolong tea powder), baking powder through a 60-mesh sieve Mix well to obtain mixed powder; put the weighed fructo-oligosaccharide, galacto-oligosaccharide and allulose sugar powder through a pulverizer to pulverize and mix evenly to prepare mixed sugar powder for later use.

[0030] Step (2) Preparation of protein paste...

Embodiment 2

[0036] Recipe: 40g wheat flour, 7g black whole wheat flour, 16g buckwheat flour, 1.5g konjac powder, 0.15g edible salt, 2g white peach oolong tea powder, 0.5g baking powder, 0.2g citric acid, 14.4g salad oil, 0.4g tartar powder , egg 200g, milk 45g, fructo-oligosaccharide 70g, galacto-oligosaccharide 15g, allulose 30g, white cocoa butter 35g, soybean lecithin 1g, γ-aminobutyric acid 0.2g.

[0037] The processing technology is as follows:

[0038] Step (1) Preparation of mixed flour, put the weighed wheat flour, buckwheat flour, black whole wheat flour, konjac powder, edible salt, white peach oolong tea powder (accounting for 2 / 3 of the total amount of white peach oolong tea powder), baking powder through a 60-mesh sieve Mix well to obtain mixed powder; put the weighed fructo-oligosaccharide, galacto-oligosaccharide and allulose sugar powder through a pulverizer to pulverize and mix evenly to prepare mixed sugar powder for later use.

[0039] Step (2) Preparation of protein pa...

Embodiment 3

[0045] Recipe: 60g wheat flour, 15g black whole wheat flour, 24g buckwheat flour, 2.5g konjac powder, 0.25g edible salt, 3g white peach oolong tea powder, 1.5g baking powder, 0.6g citric acid, 18.4g salad oil, 0.4g tartar powder , egg 280g, milk 65g, fructo-oligosaccharide 90g, galacto-oligosaccharide 25g, allulose 40g, white cocoa butter 45g, soybean lecithin 1g, γ-aminobutyric acid 0.2g.

[0046] The processing technology is as follows:

[0047] Step (1) Preparation of mixed flour, put the weighed wheat flour, buckwheat flour, black whole wheat flour, konjac powder, edible salt, white peach oolong tea powder (accounting for 2 / 3 of the total amount of white peach oolong tea powder), baking powder through a 60-mesh sieve Mix well to obtain mixed powder; put the weighed fructo-oligosaccharide, galacto-oligosaccharide and allulose sugar powder through a pulverizer to pulverize and mix evenly to prepare mixed sugar powder for later use.

[0048] Step (2) Preparation of protein p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com