Method for improving dissolution rate of triclabendazole particles and dissolution rate detection method of triclabendazole particles

A technology of triclabendazole and detection method, which is applied to a method for improving the dissolution rate of triclabendazole granules and the field of dissolution detection thereof, and can solve the problems of low dissolution rate of triclabendazole and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0026] A method for improving the dissolution rate of triclabendazole granules, the specific steps are:

[0027] (1) After screening experiments, the present invention uses triclabendazole, starch and glucose in a ratio of 1:1:8 as the main body of the prescription;

[0028] (2) Add 1 part of starch to 9 parts of water, use steam to make a uniform starch slurry, let it cool, and set aside;

[0029] (3) Add 0.5 part of sodium carboxymethyl cellulose to 99.5 parts of water, stir and dissolve to a clear solution, and set aside;

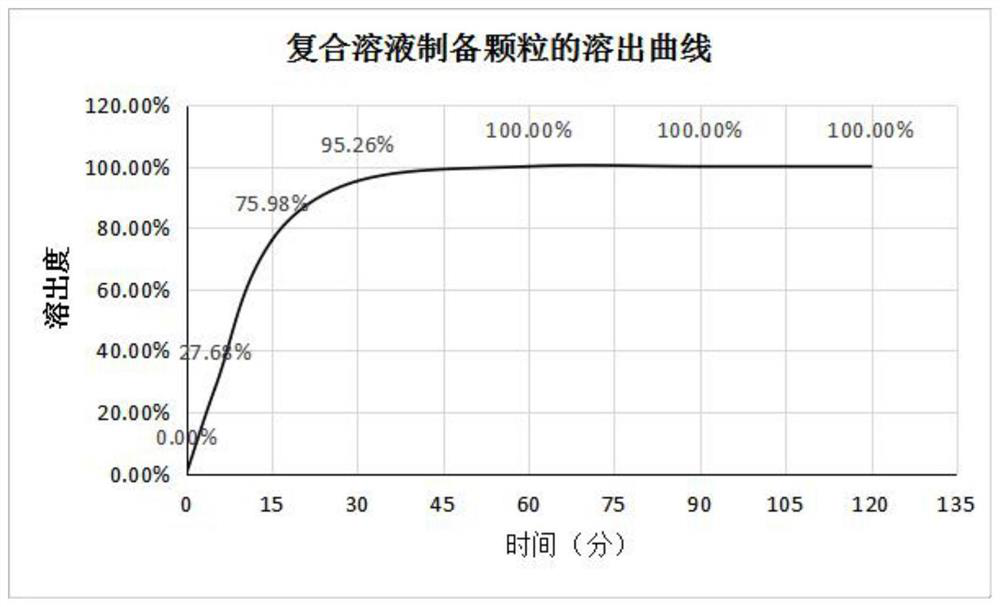

[0030] (4) Mix water, 95% ethanol, sorbitan monooleate and polyvinylpyrrolidone K30 in a ratio of 3:6:0.4:0.6, stir and dissolve until a clear and uniform solution is set aside;

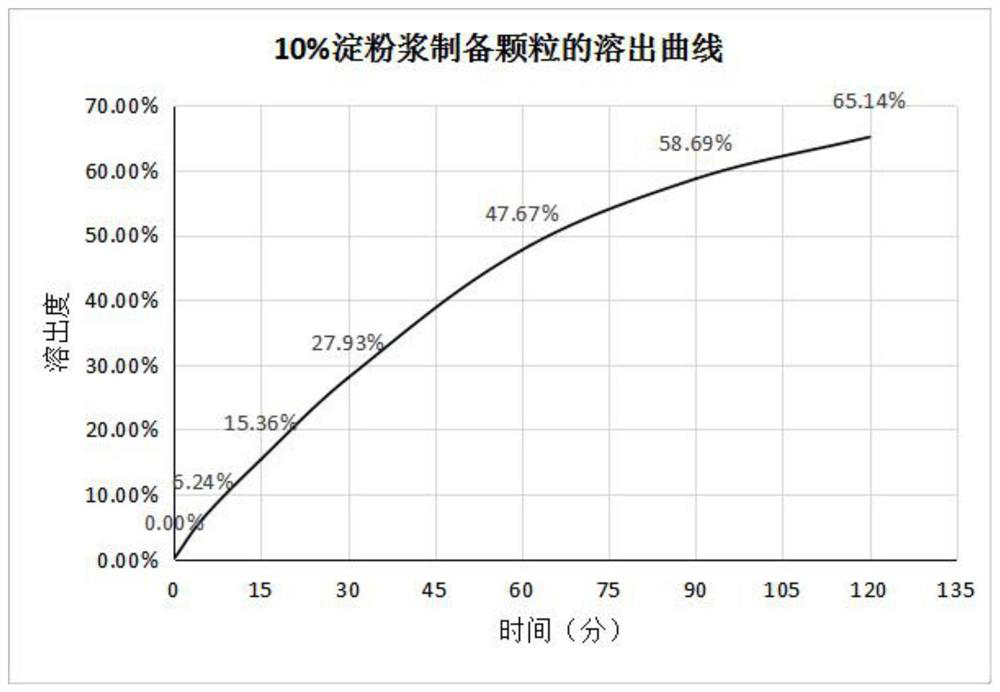

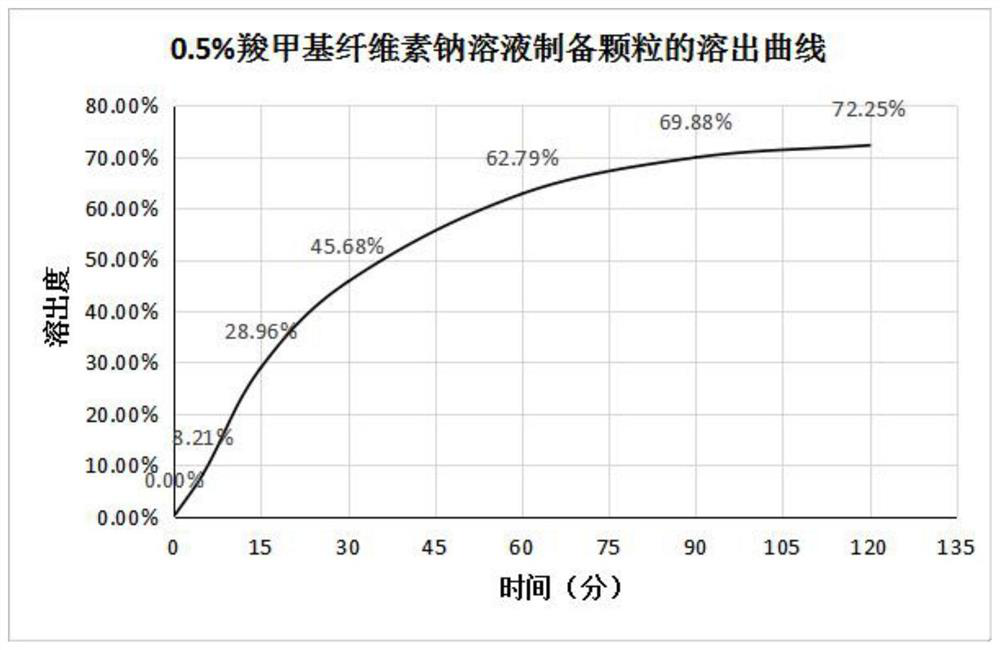

[0031] (5) Mix triclabendazol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com