A kind of compatibility ito etchant and preparation method

An etching solution and compatibility technology, applied in the field of compatible ITO etching solution and preparation, can solve the problems of strong corrosion ability of etching solution, difficult to control etching precision, severe etching reaction, etc., achieve mild and stable reaction, avoid severe etching reaction, The effect of high etching precision

Active Publication Date: 2022-06-03

JIANGYIN RUNMA ELECTRONICS MATERIAL

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The ITO etching solution used in the panel process in the existing industry usually uses hydrochloric acid / nitric acid mixed aqueous solution, hydrochloric acid / ferric chloride aqueous solution, iodic acid aqueous solution, phosphoric acid aqueous solution, etc. These etching solutions have strong corrosion ability and are often difficult to control during the etching process. Etching angle and etching time, difficult to control etching precision

[0003] Chinese patent CN201210206045.5 discloses a novel aqua regia-based ITO etching solution and its preparation method. The ITO etching solution includes hydrochloric acid, nitric acid, pure water and additives, wherein the additives include nitrate compounds, chlorine-based compounds and surfactants. The liquid has strong corrosion ability. In the etching process, it is often difficult to control the etching angle and etching time. It is not suitable for ITO films with small thickness, and the preparation process of the etching liquid is relatively complicated.

[0004] Chinese patent CN201510832036.0 discloses an ITO etchant for high-generation flat panels, the components of which include: 4-16% sulfuric acid, 7-22% nitric acid, 0.1-10% % of additives and the rest of water, sulfuric acid / nitric acid / acetic acid triacid ITO etching system is used, the acid content used is high, the etching reaction is violent, it is difficult to control the etching accuracy, and it is not suitable for ITO films with small thickness layer, and the cost of etching solution is higher

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

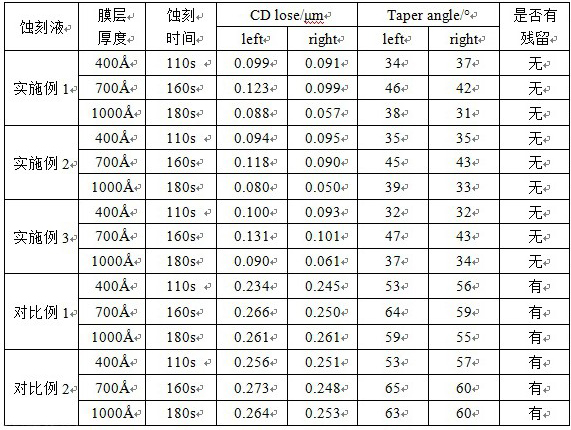

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

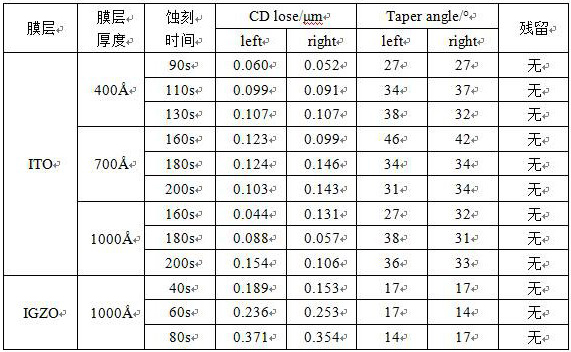

The invention relates to a compatible ITO etching solution and a preparation method. The raw materials of the etching solution are calculated by weight percentage, including 10% to 30% of nitric acid, 10% to 20% of sulfuric acid, 1% to 10% of metal salt, and 0.5% of ammonium salt. %‑3%, the balance is pure water; add nitric acid, pure water, metal salt, ammonium salt in sequence, stir well, mix evenly, then slowly add into the mixture of nitric acid, pure water, metal salt, ammonium salt Sulfuric acid, fully stirred and mixed to obtain a compatible ITO etching solution. The compatible ITO etchant of the invention is suitable for ITO film layers with different thicknesses, and has mild and stable reaction and high etching precision. For film layers of different thicknesses, the purpose of etching can be achieved only by adjusting the etching time, without changing the composition of the etchant or adjusting the composition of the etchant.

Description

A kind of compatible ITO etching solution and preparation method technical field The invention belongs to etching solution technical field, be specifically related to a kind of compatibility ITO etching solution and preparation method. Background technique [0002] The indium tin oxide (ITO) conductive film is plated on a soda lime base or borosilicate glass by a method of magnetron sputtering. Made of indium tin oxide film. ITO conductive film has low resistivity, high visible light transmittance, high infrared reflection, It has excellent adhesion and scratch resistance and is widely used in the panel display industry. To prepare the required electrode pattern shape, usually requires wet etching of the ITO conductive film. In the existing industry, the ITO etching solution usually uses salt in the process of using it as a panel. Acid / nitric acid mixed aqueous solution, hydrochloric acid / ferric chloride aqueous solution, iodic acid aqueous solution, phosphoric acid...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K13/08C09K13/04C09K13/06

CPCC09K13/08C09K13/04C09K13/06

Inventor 戈烨铭何珂汤晓春

Owner JIANGYIN RUNMA ELECTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com