A kind of leveling liquid and its preparation method and application

A technology of leveling fluid and polyacrylamide, which is used in lubricating compositions, petroleum industry, etc., can solve problems such as inability to meet different needs, and achieve the effects of excellent anti-rust performance, low surface tension and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

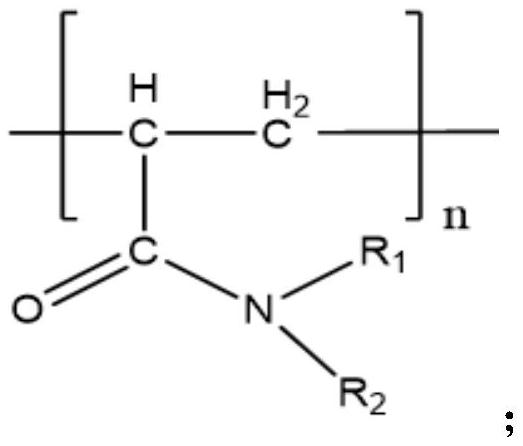

Image

Examples

Embodiment 1

[0054] A leveling liquid (1000g / L), consisting of the following components:

[0055]

[0056]

[0057] Among them, the organic amine is monoethanolamine; the organic acid is a mixed acid composed of neononanoic acid and sebacic acid in a mass ratio of 3:4; the corrosion inhibitor is benzotriazole; the surfactant is nonylphenol polyoxyethylene ether E09; The functional additive is antirust additive sebacic acid, and the mass ratio of polyacrylamide polymer and functional additive is 10:2.

[0058] The preparation method is as follows:

[0059] (1) Preparation of polyacrylamide polymers coated with functional additives

[0060] In 100 parts by weight of water, add 4 parts by weight of acrylamide and 0.5 parts by weight of N-propylacrylamide, stir vigorously, then add 2 parts by weight of potassium persulfate, raise the temperature to 50°C for 2 hours, and then add 1 part by weight of Potassium sulfate, heated to 75°C, and reacted for 2 hours to obtain a polyacrylamide po...

Embodiment 2

[0065] The difference from Example 1 is that in this example, the polyacrylamide polymer coated with functional additives is replaced by the components prepared as follows:

[0066] In 100 parts by weight of water, add 2.5 parts by weight of acrylamide and 1.0 part by weight of N-propylacrylamide, stir vigorously, then add 2 parts by weight of potassium persulfate, raise the temperature to 50°C for 2 hours, and then add 1 part by weight of persulfate Potassium sulfate, heated to 80°C, and reacted for 1 hour to obtain a polyacrylamide polymer.

[0067] Add 10 parts by weight of polyacrylamide polymer to 10 parts by weight of nonylphenol polyoxyethylene ether E09, dialyze, cool and dry to obtain polyacrylamide polymer coated with functional additives.

Embodiment 3-7

[0069] The difference with Example 2 is that the mass ratio of polyacrylamide polymer and functional additive is 10:3 (Example 3), 10:0.1 (Example 4), 10:5 (Example 5), 10: 6 (Example 6), 10:0.05 (Example 7).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com