Low-temperature selective oxidation catalyst for converting acraldehyde into acrylic acid and application thereof

A technology of selective oxidation and acrolein, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, organic compound preparation, etc., can solve the problem of catalyst deactivation and achieve the ability to resist overheating Strong, mild and stable reaction, wide operating window effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

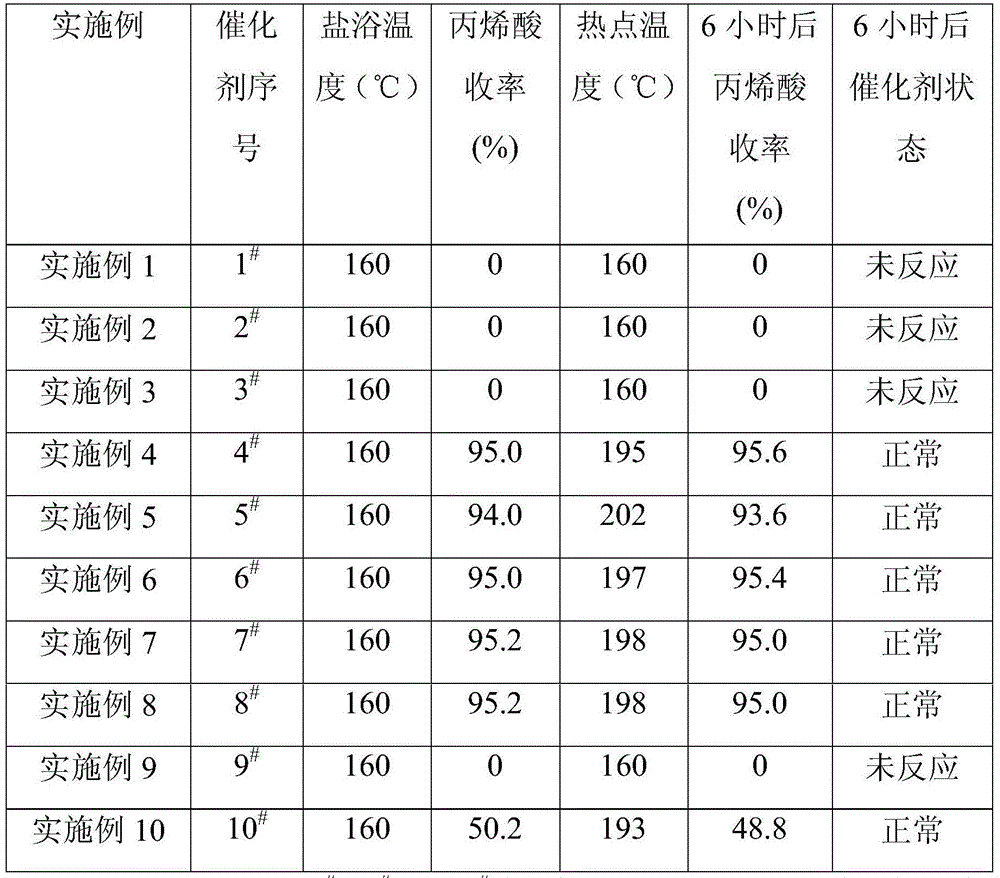

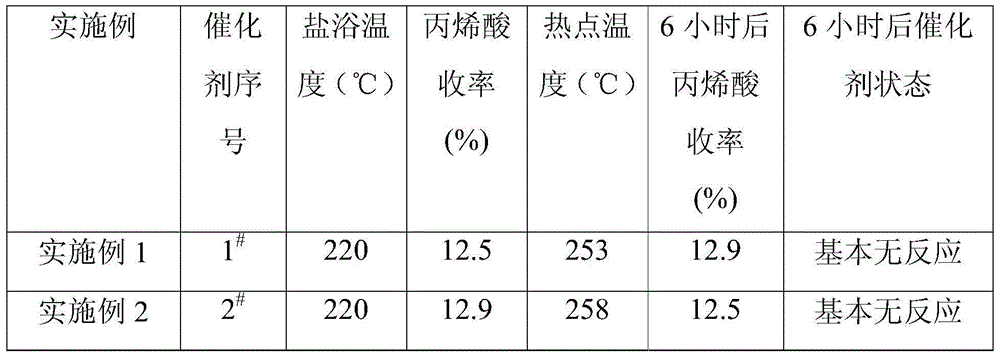

Examples

Embodiment 1

[0026] Embodiment 1: preparation of composite oxide

[0027] In a 20L five-neck flask, put 10L of distilled water, then put a certain amount of copper nitrate, nickel nitrate, ammonium metavanadate, ammonium molybdate, strontium nitrate, and magnesium nitrate into it and stir to form a slurry state, and then the mixed solution is dried by pumping it into a spray dryer, the inlet temperature of the spray dryer is 200°C, and the outlet is not lower than 80°C. The obtained dry powder was ground in a ball mill for 2 hours to obtain a fine powder, shaped on an extruder, and then calcined at 320° C. for 6 hours. The active component is Mo 12 V 3 Nb 0.5 Cu 0.4 Ni 0.8 Sb 48 Mg 0.1 o x , labeled Catalyst 1 # .

Embodiment 2

[0028] Embodiment 2: preparation of composite oxide

[0029] Other is with embodiment 1, makes Mo 12 V 3 Nb 0.5 Cu 0.4 Ni 0.8 Sb 120 Mg 0.1 o x , labeled Catalyst 2 # .

Embodiment 3

[0030] Embodiment 3: preparation of composite oxide

[0031]Other is with embodiment 1, makes Mo 12 V 3 Nb 0.5 Cu 0.4 Ni 0.8 Sb 240 Mg 0.1 o x , labeled Catalyst 3 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com