A kind of high thermal conductivity and high strength mg-al-la-mn wrought magnesium alloy and preparation method thereof

A deformed magnesium alloy, high thermal conductivity technology, applied in the field of magnesium alloy and its preparation, to achieve high strength, meet heat dissipation performance requirements, and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

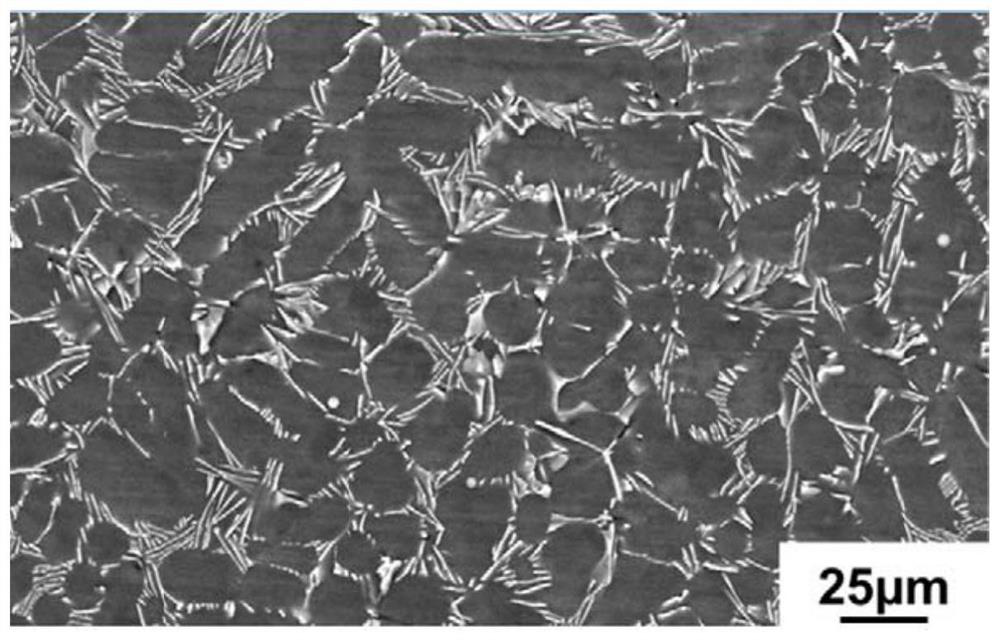

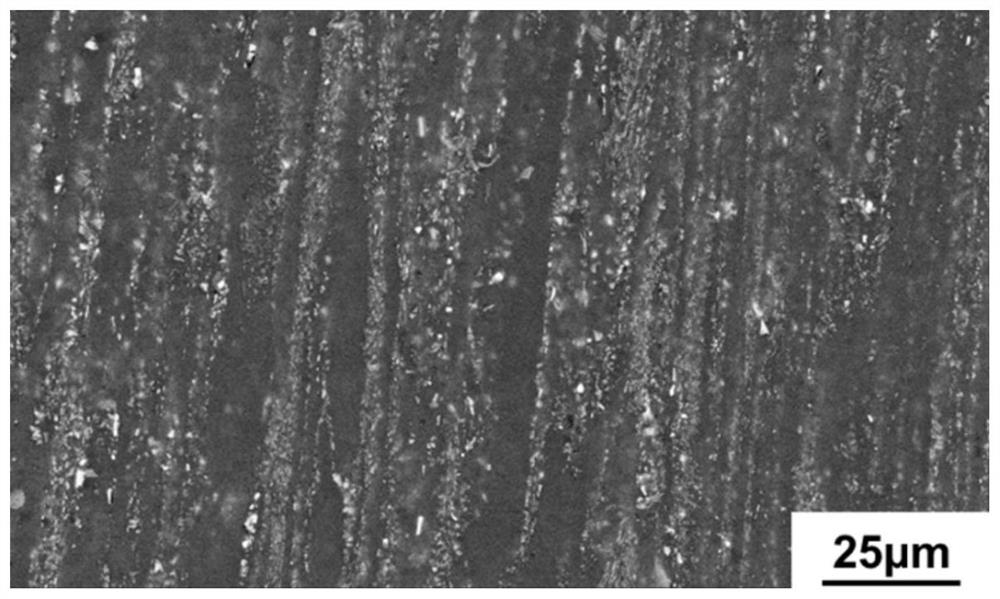

[0028] Specific implementation mode 1: The elements and contents in the high thermal conductivity and high strength Mg-Al-La-Mn deformed magnesium alloy in this embodiment are: Al: 2.8-3.5wt.%, La: 4.3-5.0wt.%, Mn: 0.28- 0.3wt.%, Mg is the balance. The alloy also contains some unavoidable impurities such as Fe and Si.

[0029] This embodiment has the following beneficial effects:

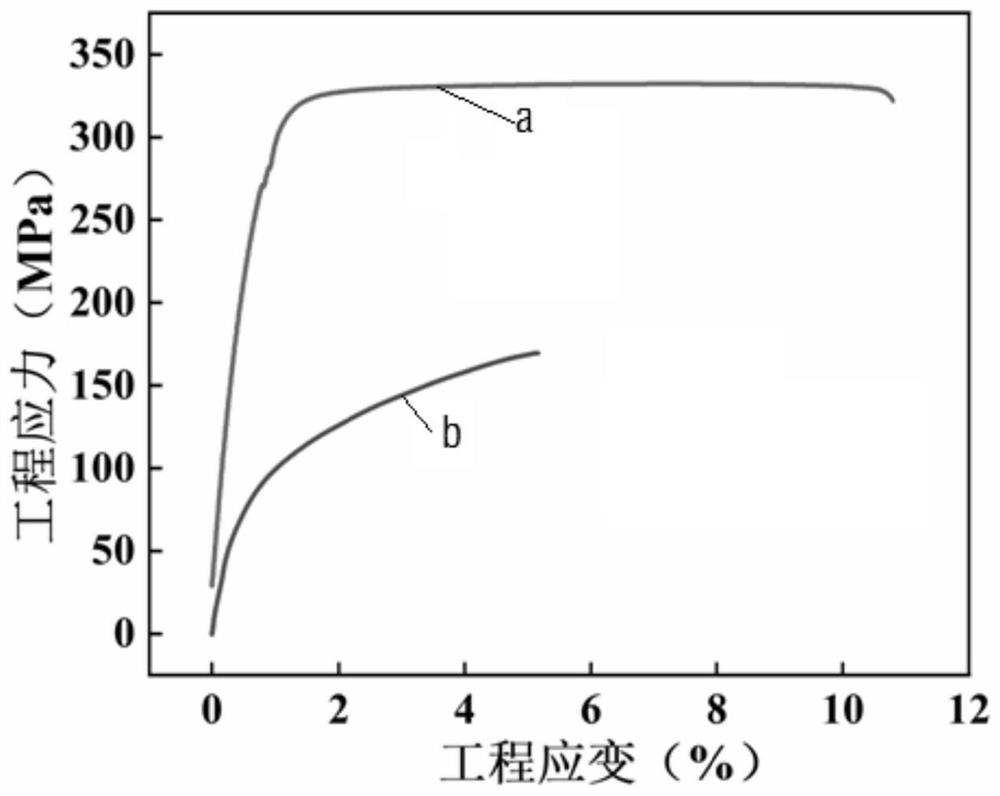

[0030] The room temperature thermal conductivity of the high thermal conductivity and high strength Mg-Al-La-Mn alloy extruded alloy of this embodiment is 112-120W / (m K), the yield strength is 245-271MPa, and the tensile strength is 318-335MPa , the elongation rate is 10%-21%. The alloy has both high thermal conductivity and high strength, and has good comprehensive performance. It can effectively meet the heat dissipation performance requirements of components such as communication equipment and electronic products. It has broad application prospects in the fields of aerospace, automobile, electr...

specific Embodiment approach 2

[0032] Specific embodiment two: The preparation method of the high thermal conductivity and high strength Mg-Al-La-Mn deformed magnesium alloy of this embodiment is carried out according to the following steps:

[0033] 1. Raw material preparation:

[0034] According to the mass percentage of elements, Al: 2.8-3.5wt.%, La: 4.3-5.0wt.%, Mn: 0.28-0.3wt.%, and the rest is Mg. Weigh Mg-Al master alloy and Mg-La master alloy , Mg-Mn master alloy and pure Mg ingot are used as raw materials to remove oxide skin and inclusions on the surface of pure Mg ingot and master alloy;

[0035] 2. Preheating: Preheat the raw materials weighed in step 1 to 200-250°C;

[0036] 3. Melting:

[0037] ①. Put the crucible into a resistance heating furnace, set the temperature of the heating furnace to 750-760°C, when the temperature of the crucible reaches 600°C-650°C, feed SF 6 and CO 2Mix the protective gas, and put the pure Mg ingot obtained in step 2 into the crucible for smelting. After 30-45...

specific Embodiment approach 3

[0047] Specific embodiment three: the difference between this embodiment and the second embodiment is that in step one, the mass percentage of elements is Al: 2.8wt.%, La: 5.0wt.%, Mn: 0.3wt.%, and the rest is Mg, which is called Take the ingredients.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com