Heat slow-release element with layered structure, and application of heat slow-release element in thermal battery

A layered structure and thermal technology, applied in the direction of primary battery use/maintenance, battery cooling/heating, delayed action cells, etc., can solve the problem of rapid internal temperature drop rate, achieve slow down rate, improve performance, and have wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

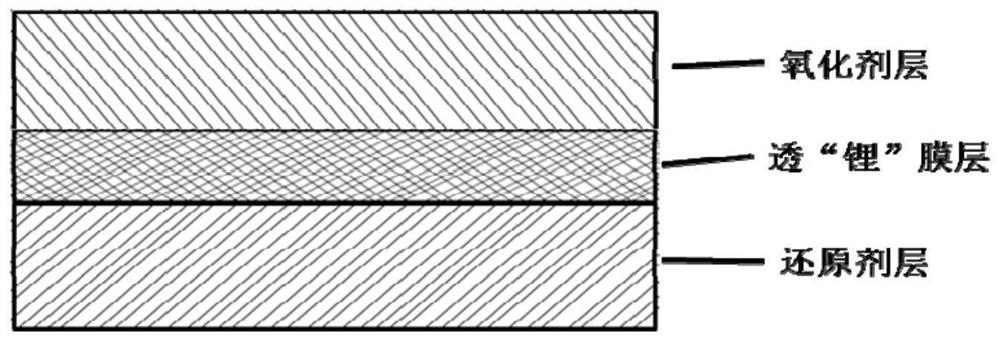

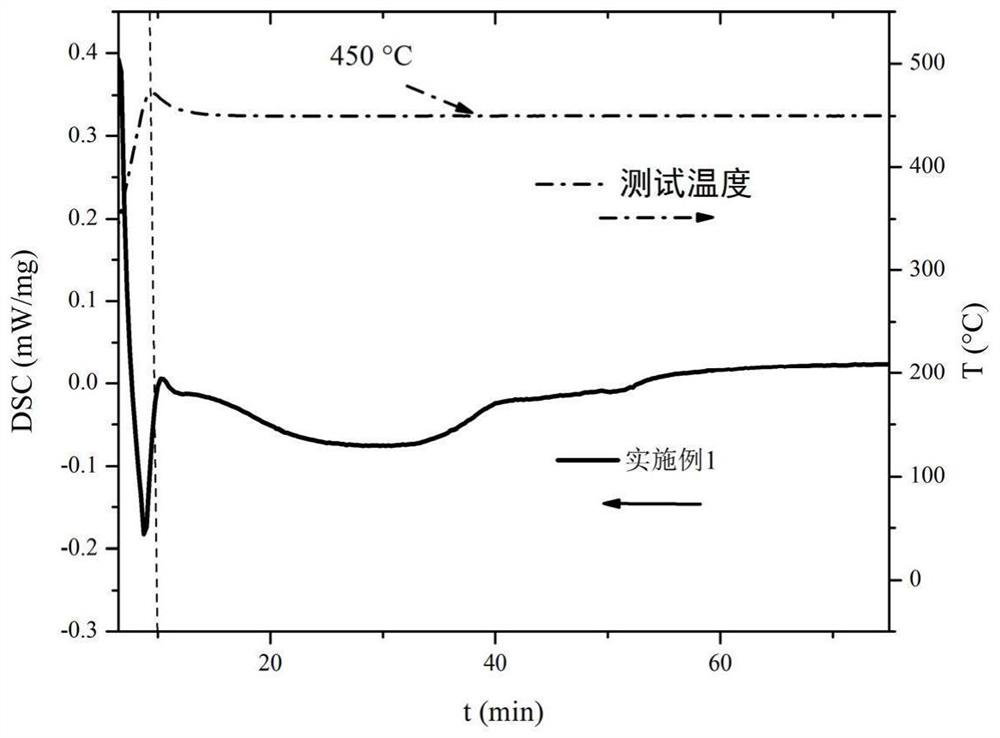

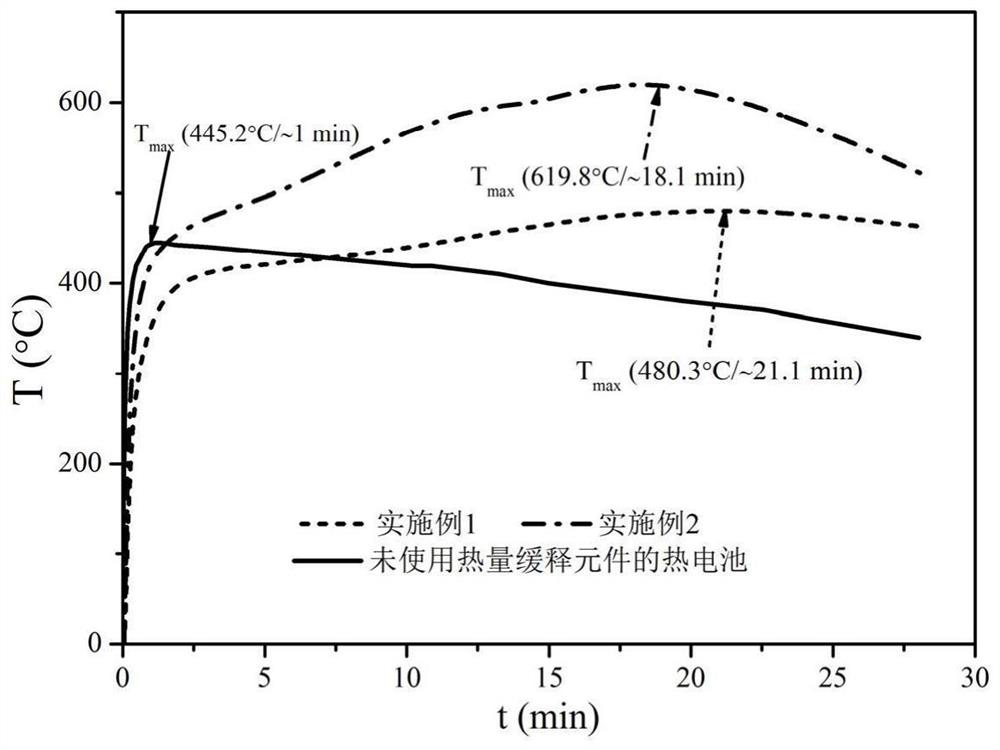

[0036] This embodiment provides a heat slow-release element with a layered structure and its application in thermal batteries, including:

[0037] 1) Heat slow-release element with a layered structure: composed of 0.2g reducing agent powder, 0.3g "lithium" thin-layer powder, and 0.3g oxidant powder, pressed according to cold isostatic pressing, wherein The reducing agent is Li-Si alloy (44wt.% Li), and the "lithium" thin-layer powder is composed of 40wt.% LiCl-37wt.% LiBr-52wt.% KBr and 60wt.% CeO 2 Composition, the oxidant powder is composed of 80wt.% CuO and 20wt.% LiCl-KCl-LiBr.

[0038] 2) Thermal battery with layered heat slow-release elements: except that two layered heat slow-release elements are placed at both ends of the thermal battery cell stack, other aspects are consistent with the traditional thermal battery manufacturing and assembly process.

Embodiment 2

[0040] This embodiment provides a heat slow-release element with a layered structure and its application, including:

[0041] 1) Heat slow-release element with a layered structure: composed of 0.3g reducing agent powder, 0.4g "lithium" thin-layer powder, and 0.4g oxidant powder, pressed according to cold isostatic pressing, wherein The reducing agent is Li-B alloy (55wt.% Li), and the "lithium" thin-layer powder is composed of 50wt.% LiCl-55wt.% KCl, 50wt.% Sm 2 o 3 Composition, the oxidant powder is CuO;

[0042]2) Thermal battery containing layered heat slow-release elements: except that two layered heat slow-release elements are placed at both ends of the thermal battery cell stack and one is placed in the middle of the thermal battery stack, other aspects are different from traditional thermal cells. The battery manufacturing and assembly process remains the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com