Automatic clamping device of mechanical polishing equipment

A technology of mechanical polishing and clamping device, which is applied in the direction of grinding/polishing equipment, grinding drive device, surface polishing machine tool, etc. It can solve the problem of indetermination of product qualification, affecting the production efficiency and aesthetics of metal handles, and polishing device Problems such as inability to detect surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

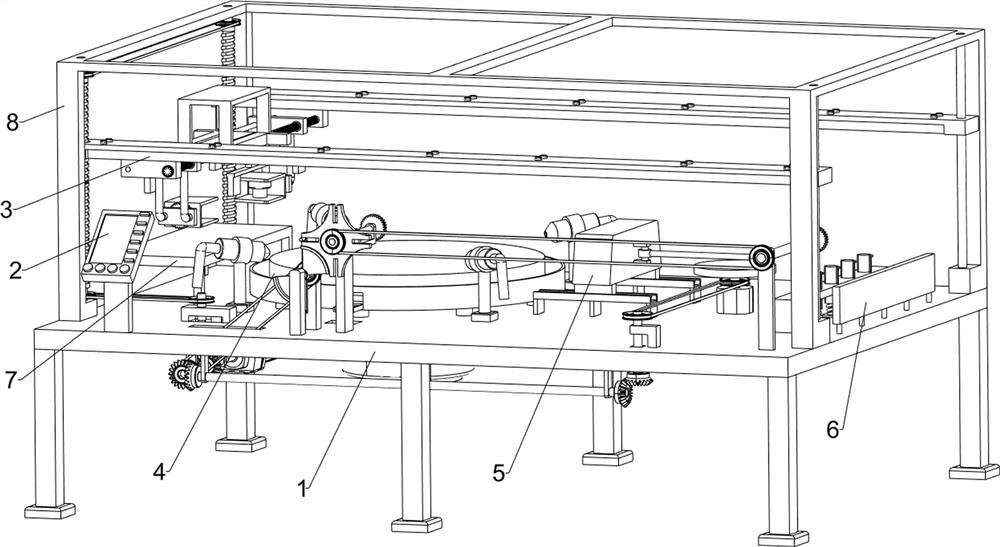

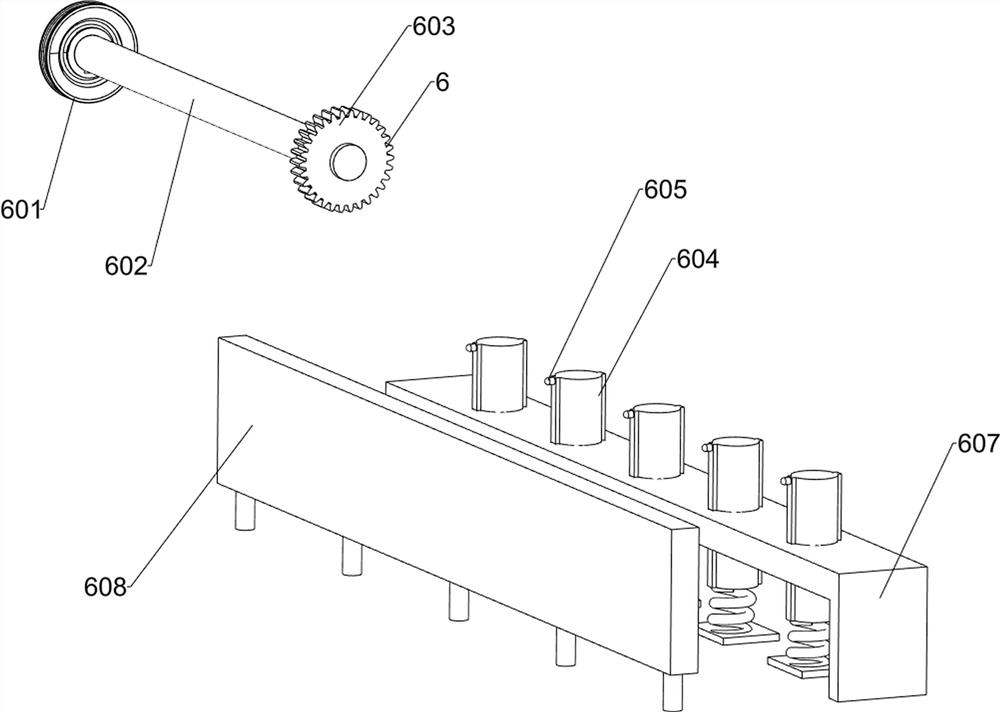

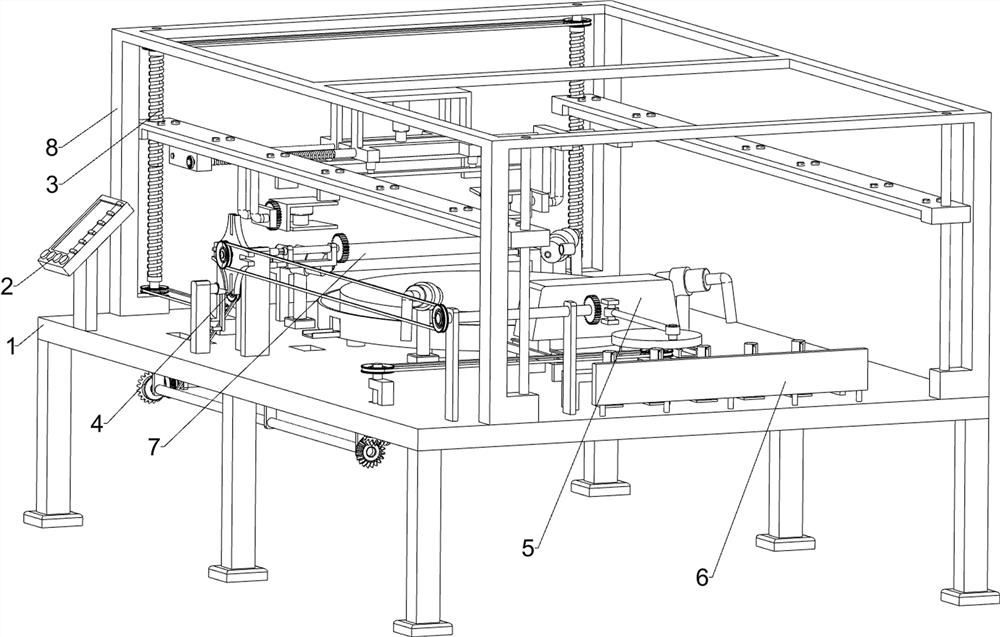

[0034] An automatic clamping device for mechanical polishing equipment, such as Figure 1-11 As shown, it includes a support base plate 1, a control panel 2, a clamping and conveying system 3, an outer surface polishing system 4, an inner arc surface polishing system 5, a detection system 6, a stage 7 and a fixing frame 8; the support base plate 1 and the control The screen 2 is connected; the support base 1 is connected with the outer surface polishing system 4, the inner arc surface polishing system 5 and the detection system 6 in sequence; the support base 1 is connected with the stage 7; the support base 1 is connected with the fixed frame 8; The outer surface polishing system 4 is connected with the inner arc surface polishing system 5 ; the outer surface polishing system 4 is connected with the detection system 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com