Novel combined equipment suitable for granulating/crushing high polymer materials by grinding method

A polymer and new combination technology, applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve problems such as poor product quality, environmental pollution, and flying dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A new combination equipment suitable for milling granulation / crushing polymer materials, said "new combination equipment" is characterized by Example 1-1, or Example 1-1 and Example 1-2 to Example 1-3 Any or a combination of:

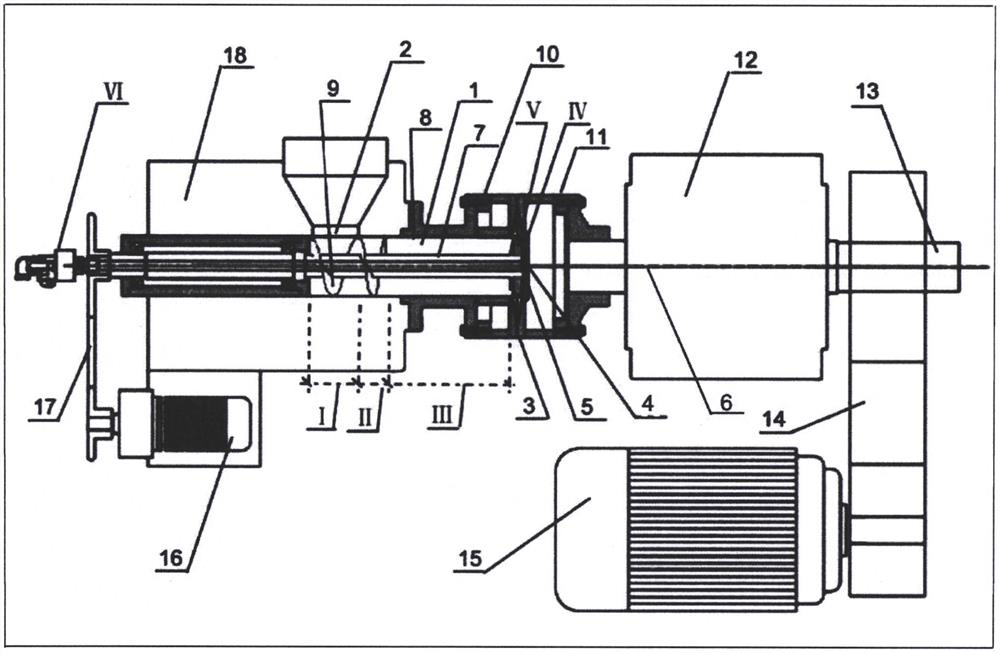

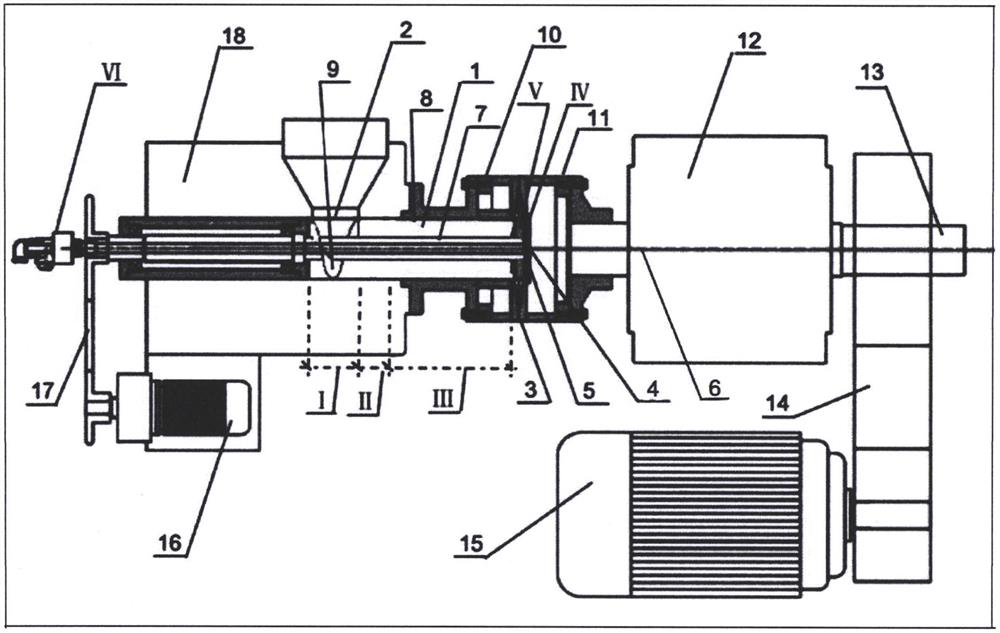

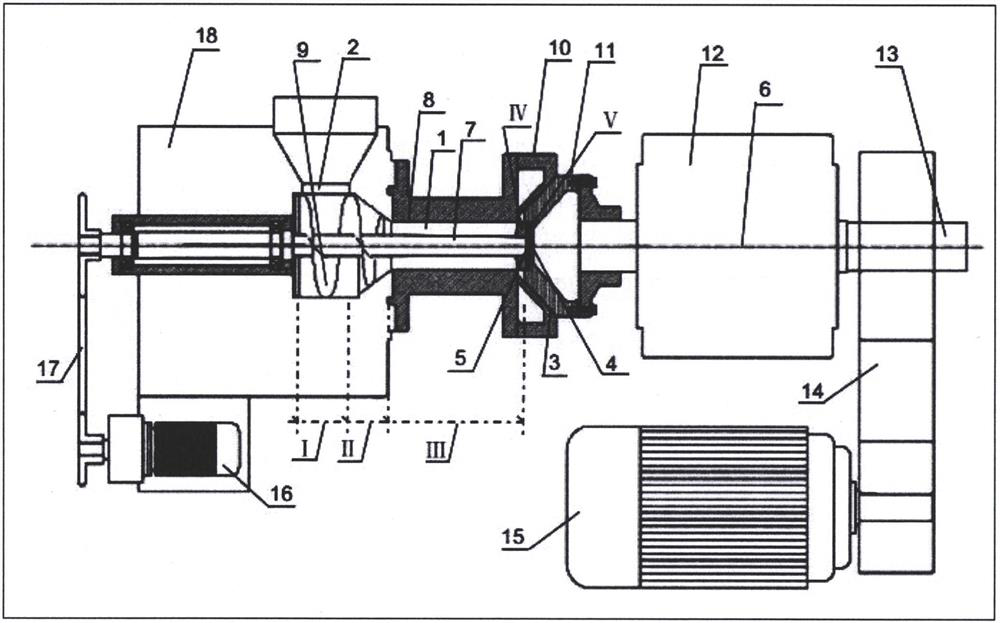

[0078] Example 1-1. Combined sub-equipment A with at least a milling mechanism, as attached Figure 11 said, Figure 11 The "grinding mechanism" carried in A can at least choose the bulk density of the polymer material to be ≥0.06kg / L, and at least coarse waste paper regenerated through a 2-mesh sieve, miscellaneous waste plastic film Or / and waste agricultural plastic film as a calibration object, as attached Figure 13 It is the black-and-white photo of waste plastic film discarded from the recycling of waste paper passing through the 2-mesh sieve, and its bulk density is ≥0.06kg / L. If waste agricultural plastic film is selected as the calibration object, its black-and-white photo graph with Figure 13 It is almost the same, when the "calibr...

example 1-2

[0079] Example 1-2. As attached Figure 11 As mentioned above, before A, there is a secondary crushing combination sub-device C for grading or mixing the elastomer or / and plastic in the polymer material to any mesh size of 2 to 40, and before C, there is a secondary crushing sub-device C. Cleaning / sorting combined sub-device B of elastomers in molecular materials or / and waste plastics; after A, a combined sub-device D with a magnetic separator is connected, or / and a combined sub-device E with an electric field separator is connected , or / and connect the combined sub-device F containing the color sorter;

example 1-3

[0080] Example 1-3. As attached Figure 11 As mentioned above, before A, there is a secondary crushing combination sub-device C for grading or mixing the polymer elastomer or / and plastic in the polymer material to any mesh size of 2 to 40, and before C, there is a Combination sub-device B for cleaning / separating polymer elastomers or / and waste plastics in polymer materials; sub-device G for primary crushing is connected before B; sub-device D with a magnetic separator is connected after A , or / and connecting the combination sub-device E carrying the electric field separator, or / and connecting the combination sub-device F containing the color sorter; or / and connecting the combination sub-device D carrying the magnetic separator after C and before A , or / and connecting with the combined sub-device E carrying the electric field separator, or / and connecting with the combined sub-device F containing the color sorter;

[0081] The "connection" mentioned in 1-2 / 1-3 above refers to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com